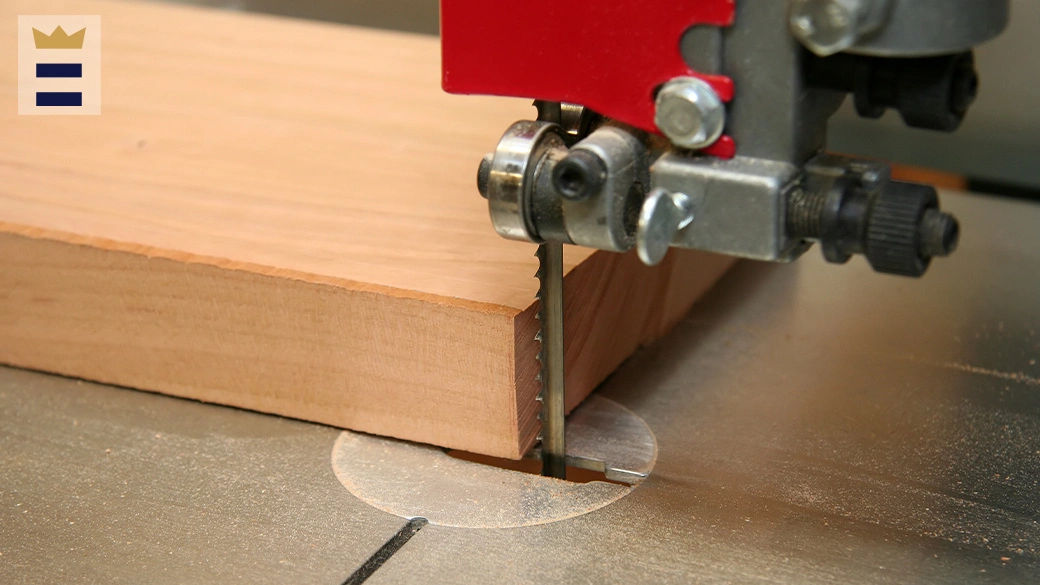

Are you looking for the best band saw blade for your projects? You are in the right place! This article serves to guide you in selecting the right band saw blade that is suitable for your specific application. Our comprehensive buying guide will help you find the perfect saw blade that meets your needs and budget.

Best band saw blade 2023

- POWERTEC 13104 TPI Band Saw Blade (Editor’s pick)

- BOSCH BS80-6H 6-Tpi Saw Blade (Best Overall)

- POWERTEC 13212 TPI Band Saw Blade (Budget Friendly)

- BOSCH BS6412 Metal Bandsaw Blade

- Imachinist S933414 M42 Band Saw

- Imachinist S6412121014 Bi-Metal Saw Blades

- Milwaukee 48-39-0529 Band Saw Blade

1) POWERTEC 13104 TPI Band Saw Blade

The tooth arrangement of the POWERTEC 13104 TPI Band Saw Blade makes it effective. These teeth are strategically designed for clean, precise cuts by professional and DIY woodworkers.

Unmatched Durability

No one enjoys blade replacements. The POWERTEC 13104 TPI Band Saw Blade lasts longer than most. This strong steel alloy blade is heavy-duty. POWERTEC is classic.

Your Ideal Friend

The POWERTEC 13104 TPI Band Saw Blade is crucial for DIYers and pros. 5.9 x 4.7 x 0.5 inches makes it easy to keep in your workspace. The sleek silver colour conveys professionalism and superior quality. This blade stands out with 18 teeth for precise cuts.

Easy Compatibility

The flexible POWERTEC 13104 TPI Band Saw Blade. Its 59.5″ x 3/8″ x 18TPI characteristics work with various band saw models, making it popular with pros and DIYers. Installation is easy without tools. Quality and usability make this the best choice.

Conclusion

The POWERTEC 13104 TPI Band Saw Blade is precise, durable, and compatible. This outstanding blade will improve your cutting experience, whether you’re a craftsman or a hobbyist. Try POWERTEC today to witness the difference.

Must Read – Best 7 inch wet tile saw blade

POWERTEC 13104 TPI Band Saw Blade First Hand Review Video

Video Source: Tools Informer

Pros:

- Made of durable steel alloy

- Compact item dimensions of 5.9 x 4.7 x 0.5 inches

- 18 teeth for clean and precise cuts

- Compatible with a wide range of band saw models

- Easy to install

CORE FEATURE

| Material | Steel Alloy |

| Brand | POWERTEC |

| Item Dimensions LxWxH | 5.9 x 4.7 x 0.5 inches |

| Color | Silver |

| Number of Teeth | 18 |

| Style | 1 Pack |

| Item Weight | 0.1 Pounds |

| Domestic Shipping | Item can be shipped within U.S. |

| Part Number | 13104X |

2) BOSCH BS80-6H 6-Tpi Saw Blade

The BOSCH BS80-6H 6-Tpi Saw Blade uses an adapter that fits most saws. This versatility opens up woodworking options. The BOSCH BS80-6H 6-Tpi Saw Blade fits any saw.

Size Matters

Its 80mm length gives it a wide cutting range. No more frequent blade changes during projects. The BOSCH BS80-6H 6-Tpi Saw Blade lets you work across many projects without interruption.

The 6-Tpi Design Redefined Precision

This blade’s 6-Tpi design ensures precise cutting for seamless craftsmanship. Enjoy smooth cuts in softwoods, hardwoods, and plywood. Precision is impossible with the BOSCH BS80-6H 6-Tpi Saw Blade.

Excellence meets durability

Built to Last

Premium steel makes this blade hold strong amid adversity. Applications that are heavy? No issue. The durable BOSCH BS80-6H 6-Tpi Saw Blade is your constant companion.

Compact Convenience Size Matters

The small BOSCH BS80-6H 6-Tpi Saw Blade is 1 x 9.88 x 10.88 inches. Its sleek silver finish adds professionalism and makes storage easy. Efficiency doesn’t compromise space with this tool.

A Universal Fit for Maximum Compatibility

With its wood-friendly design, this blade fits most band saw sizes. For professionals and DIYers alike, the BOSCH BS80-6H 6-Tpi Saw Blade provides the whole package.

Precision Perfected: The Ultimate Woodworking Companion

The optimized tooth design of the BOSCH BS80-6H 6-Tpi Saw Blade ensures top performance. With its premium-grade steel, this blade can handle the toughest labour conditions. Woodworking pros, this is your key to success.

Finally, the BOSCH BS80-6H 6-Tpi Saw Blade is a symbol of precision, durability, and versatility. Improve your woodworking tasks with a high-quality blade. Trust the BOSCH BS80-6H 6-Tpi Saw Blade and experience woodworking like never before.

Must Read – Best 8 1/4 table saw blade

BOSCH BS80-6H 6-Tpi Saw Blade First Hand Review Video

Video Source: RICHARD HOWARD

Pros:

- Optimized tooth geometry for best performance

- Made from premium grade steel for durability

- Compatible with wood as a material

- Compact item dimensions of 1 x 9.88 x 10.88 inches

- Designed to fit most common band saw sizes

CORE FEATURE

| Material | Wood,Steel |

| Brand | BOSCH |

| Item Dimensions LxWxH | 1 x 9.88 x 10.88 inches |

| Color | Silver |

| Number of Teeth | 6 |

| Style | Band Saw Blade Only |

3) POWERTEC 13212 TPI Band Saw Blade

Duracraft construction gives the POWERTEC 13212 TPI Band Saw Blade remarkable durability. This cutting-edge material lets the blade tackle heavy jobs without sacrificing precision. Eliminate blade replacements and enjoy steady performance.

Precision Redefined

Geometric design distinguishes this blade from competitors. Finessefully handles even the most complex cuts. This precision is due to the POWERTEC 13212 TPI Band Saw Blade’s invention. Whether you’re a pro woodworker or a DIYer, this blade will alter your workspace.

Versatility meets quality

The POWERTEC 13212 TPI Band Saw Blade is the best option for professionals and DIYers who want a durable, high-quality blade. Its carbon steel construction makes it a durable cutting tool for heavy-duty use.

Compact and Useful

This blade is compact and easy to store at 11.81 x 9.45 x 0.39 inches, saving workplace space. Its sleek black appearance adds professionalism to your instruments, and its 24 teeth per inch ensure clean, precise cuts on wood, aluminium, and plastic. This adaptability makes it essential for professionals and DIYers.

Cutting-Edge Compatibility

Wide material compatibility is a highlight of the POWERTEC 13212 TPI Band Saw Blade. This makes it ideal for those who work with varied materials and need a blade that can cut easily. With 24 teeth per inch, this blade cuts cleanly and precisely, delivering high-quality products.

Finally, the POWERTEC 13212 TPI Band Saw Blade represents precision, durability, and innovation. This blade is necessary for skilled craftsmen and DIYers alike. The POWERTEC 13212 TPI Band Saw Blade combines accuracy and fineness to enhance your cutting experience and expand your options.

Must Read – Best 10 inch table saw blade

POWERTEC 13212 TPI Band Saw Blade First Hand Review Video

Video Source: Record Power

Pros:

- Made of durable carbon steel

- Compact item dimensions of 11.81 x 9.45 x 0.39 inches

- 24 teeth per inch for clean and precise cuts

- Compatible with a variety of materials including wood, aluminum, and plastic

- Designed to provide resistance during heavy-duty use

CORE FEATURE

| specifications | TEETH SPECS: 24tpi (24 Teeth per Inch) |

| Material | Carbon Steel |

| Brand | POWERTEC |

| Item Dimensions LxWxH | 11.81 x 9.45 x 0.39 inches |

| Color | Black |

| Number of Teeth | 24 |

| Style | Resistance |

| Compatible Material | Wood, Aluminum, Plastic |

| Part Number | 13212 |

4) BOSCH BS6412 Metal Bandsaw Blade

BOSCH BS6412 Metal Bandsaw Blades are unmatched in precision. The longer length gives you stability and control for a smooth cutting experience, not just size. This blade is ideal for people who expect high-quality cuts due to its razor-sharp edges.

Precision in Every Cut

The BS6412 Metal Bandsaw Blade cuts metal and other materials precisely. The combination of extended length and sharp edges gives users unmatched stability and control. This blade makes clean, accurate cuts easy. The BOSCH BS6412 Metal Bandsaw Blade is the best for precision and performance.

Professional Durability Unmatched

The BOSCH BS6412 Metal Bandsaw Blade is essential for metalworking experts. This blade is made of high alloy steel for heavy-duty application. Bosch is known for its high-quality products, and this bandsaw blade continues that legacy.

Protecting against Heat

The BOSCH BS6412 Metal Bandsaw Blade resists heat buildup, extending its longevity. This is especially important in metallurgy, where friction can sear blades. This blade is durable and suited for the toughest jobs, so professionals can rest assured.

Compact, User-Friendly Design

The 10.8 x 9.8 x 1-inch BOSCH BS6412 Metal Bandsaw Blade is small. This site is easy to store and carry. Its 24 precision-cutting teeth and sleek silver color make it look professional. This 4.8-ounce industrial-style blade is easy to handle and maneuver throughout projects.

Finally, the BOSCH BS6412 Metal Bandsaw Blade excels in metalworking precision and durability. It stands out because to its length, sharp edges, and heat resistance. Take quality to the next level with this tool for dependably great metalworking results.

Must Read – Best 12 inch miter saw blade

BOSCH BS6412 Metal Bandsaw Blade First Hand Review Video

Video Source: MitGreen TV

Pros:

- Made from premium grade alloy steel

- Resists heat build-up for longer life

- Compact item dimensions of 10.8 x 9.8 x 1 inches

- 24 teeth for clean and precise cuts

- Designed in an industrial style for heavy-duty use

CORE FEATURE

| Material | Alloy Steel |

| Brand | BOSCH |

| Item Dimensions LxWxH | 10.8 x 9.8 x 1 inches |

| Color | Silver |

| Number of Teeth | 24 |

| Style | Industrial |

| Item Weight | 4.8 Ounces |

5) Imachinist S933414 M42 Band Saw

Imagine customising your tool’s cutting speed for your project. The Imachinist S933414 M42 Band Saw does. Its variable speed controls cutting delicate or tough materials. Its adaptability makes it perfect for various uses.

Better Performance with Multiple Blades

The Imachinist S933414 M42 Band Saw’s M42 blade compatibility displays its versatility. This feature allows you pick the right blade for your job. The Imachinist S933414 M42 Band Saw is precise and efficient for professionals and DIYers.

Professionally Cutting Soft Ferrous Metal

The Imachinist S933414 M42 Band Saw transforms soft ferrous metal cutting. A high-quality bi-metal blade made of M42 grade steel, noted for its wear resistance and durability. This Imachinist band saw blade is high-quality.

Power from Bi-Metal and M42

Imachinist S933414 M42 Band Saw’s bi-metal and M42 grade construction ensure durability and wear resistance. The 14 blade teeth cut mild ferrous metal cleanly and precisely, providing a flawless output.

Compact and User-Friendly

The tiny 11.02 x 11.02 x 1.97-inch Imachinist S933414 M42 Band Saw is easy to store. Silky silver lends your desk refinement. This tool is lightweight and fatigue-free at 310 grammes. Professionals prefer high-quality bi-metal and M42 blades.

Conclusion

The Imachinist S933414 M42 Band Saw is a versatile and accurate professional and DIY cutting instrument. Its variable speed, M42 blade compatibility, and great craftsmanship ensure good cutting. Experience the difference between Imachinist and cutting.

Must Read – Best 12 sliding compound miter saw blade

Imachinist S933414 M42 Band Saw First Hand Review Video

Video Source: HowMuchBest

Pros:

- Made from high-quality M42 grade steel

- Designed to provide high wear resistance and toughness

- Compact item dimensions of 11.02 x 11.02 x 1.97 inches

- 14 teeth for clean and precise cuts

- Ideal for cutting soft ferrous metal

CORE FEATURE

| specifications | Perfect for cutting soft ferrous metal |

| Is Discontinued By Manufacturer : | No |

| Product Dimensions : | 11.02 x 11.02 x 1.97 inches; 10.93 Ounces |

| Country of Origin : | China |

| Brand | Imachinist |

| Item Dimensions LxWxH | 11.02 x 11.02 x 1.97 inches |

| Color | Silver |

| Number of Teeth | 14 |

| Style | Bi-metal type, M42 grade |

| Item Weight | 310 Grams |

6) Imachinist S6412121014 Bi-Metal Saw Blades

Bi-Metal Saw Blades Imachinist S6412121014 are developed for perfection. Their sleek silver finish adds modernism and durability. The blades are designed to effortlessly cut through several fabrics.

Long-lasting Sharpness for Great Performance

These blades are known for their long-lasting sharpness. This reduces blade changes, making jobs faster. The blade’s gentler edge makes precise cuts and reduces material damage. In conclusion, Imachinist S6412121014 Bi-Metal Saw Blades are a reliable and high-quality option for diverse and durable cutting.

Created for Pros

Imachinist S6412121014 Bi-Metal Saw Blades are designed for professionals that need high-quality, robust blades for cutting projects. These bi-metal blades cut soft metals well because to their wear resistance and hardness. This saw blade is from Imachinist, known for its high-quality goods.

Soft Metal Cutting Precision

The Imachinist S6412121014 Bi-Metal Saw Blades’ soft metal cutting capability is unique. This unique feature gives professionals confidence that they are utilising a blade designed for them. These blades work with several metals, making them useful for experts.

Compact, User-Friendly Design

The Imachinist S6412121014 Bi-Metal Saw Blades are compact and easy to store at 7.48 x 7.48 x 1.18 inches. Their silver exterior communicates modernism and expertise. At 160 grammes, these blades are lightweight and easy to use. They meet the high-quality needs of experts who use precision cutting tools by providing excellent wear resistance and durability.

Finally, Imachinist S6412121014 Bi-Metal Saw Blades provide precision, durability, and versatility. This blade is perfect for professionals who need a reliable instrument or hobbyists who want great results. Improve your cutting efficiency with Imachinist and see results in every cut.

Must Read – Best band saw blade for stainless steel tubing

Imachinist S6412121014 Bi-Metal Saw Blades First Hand Review Video

Video Source: HowMuchBest

Pros:

- Made from high-quality bi-metal

- Designed to provide high wear resistance and toughness

- Compact item dimensions of 7.48 x 7.48 x 1.18 inches

- Ideal for cutting soft metal

- Compatible with metal as a material

CORE FEATURE

| specifications | Perfect for cutting soft metal only |

| Is Discontinued By Manufacturer : | No |

| Product Dimensions : | 7.48 x 7.48 x 1.18 inches; 5.64 Ounces |

| Brand | Imachinist |

| Item Dimensions LxWxH | 7.48 x 7.48 x 1.18 inches |

| Color | Silver |

| Style | Modern |

| Item Weight | 160 Grams |

| Compatible Material | Metal |

7) Milwaukee 48-39-0529 Band Saw Blade

The Milwaukee 48-39-0529 Band Saw Blade is your key to better performance. Its innovative design boosts power for smooth, precise cuts in a variety of materials. Not simply finishing the work, but doing it smoothly and perfectly.

Professional Durability

This blade, made for professional use, never gives up. It’s durable and reliable for experienced contractors but approachable for beginners. The Milwaukee 48-39-0529 Band Saw Blade is reliable and versatile, perfect for your workshop. This band saw blade is the perfect cutting companion due to its power, portability, and cutting-edge design.

Built to Last

Professionals need a durable blade for cutting. Milwaukee 48-39-0529 Band Saw Blades are made of alloy steel for durability and hardness, making them ideal for cutting iron, metal, and copper. Milwaukee band saw blades are known for quality.

Precision Fundamental

The 35-3/8″ x 1/2″ x.020″ Milwaukee 48-39-0529 Band Saw Blade has amazing specs. These standards ensure professionals receive a blade tailored to their needs. Its 18 teeth per inch make it suitable for precision cutting.

Compact & Handy

This band saw blade is powerful and useful. Its 15.04 x 7.01 x 0.79-inch dimensions make it portable and easy to store. Its silver sheen radiates professionalism, and at 7 ounces, it’s easy to operate. This versatile blade works with iron, metal, and copper, making it the best choice for professionals working with various materials.

Finally, the Milwaukee 48-39-0529 Band Saw Blade is a precision tool. Power, durability, and convenience are combined in this professional product. With a blade that exceeds your cutting needs, elevate your craftsmanship. For quality, consider the Milwaukee 48-39-0529 Band Saw Blade.

Must Read – Best blade for radial arm saw

Milwaukee 48-39-0529 Band Saw Blade First Hand Review Video

Video Source: FIX Tech Guides

Pros:

- Made from high-quality alloy steel

- Designed to provide high wear resistance and toughness

- Compact item dimensions of 15.04 x 7.01 x 0.79 inches

- 18 teeth per inch for precision cutting tasks

- Compatible with a variety of materials, including iron, metal, and copper

CORE FEATURE

| Material | Alloy Steel |

| Brand | Milwaukee |

| Item Dimensions LxWxH | 15.04 x 7.01 x 0.79 inches |

| Color | Silver |

| Number of Teeth | 18 |

| Style | Portable,Compact |

| Compatible Material | Iron, Metal, Copper |

Best band saw blade 2023-Complete buying Guide

The band saw is one of the power tools used by many professional carpenters, woodworkers, and hobbyists alike for their cutting needs. In order to ensure efficiency, performance, and safety, however, it’s essential to invest in the best band saw blade you can.

A band saw blade is an essential component of a band saw and has a particular purpose according to its shape and dimensions. Therefore, when browsing through options available in the market today it’s important that you understand the different types of blades as well as their various characteristics in order to make an informed purchase.

In this guide we will provide a comprehensive overview on the most important aspects related to purchasing the best band saw blade; from understanding various types of blades (ranging from regular-tooth blades to skip-tooth blades) to determining which blade works best for your job. So whether you’re cutting softwood or hardwood—we’ve got all your questions covered!

Photo Source: wfxrtv.com

Definition of Band Saw Blade

A band saw blade is a continuous toothed metal cutting strip with sharp edges used in a band saw machine. Band saw blades are an essential tool for many professionals and amateur woodworkers alike as they allow for quick, accurate, and safe cutting of wood, non-ferrous metals, plastic, and composite materials.

Band Saw Blade construction can vary widely depending on the application, but generally consists of two opposing curved plates that meet in the middle to form a toothless gullet between them. The teeth can then be applied either along the full length or just at the ends of the blade as per the particular material being cut. Commonly available configurations include blades specifically designed for making:

- Rip cuts

- Crosscuts

- Miter cuts

- Resawing

- Arch cutting

allowing for a wide range of materials to be cut with high precision and minimal vibrations. Band saw blades may also incorporate anti-kickback designs which are important elements when working with especially hard materials or highly viscous plastics.

Importance of Choosing the Right Blade

Choosing the right blade for your band saw is essential for getting the most out of your machine, as well as helping you work safely and effectively. The type of blade you need can vary depending on the size of the band saw, material you are cutting, and application. It is important to learn what factors make up a quality blade in order to choose the best one for your needs.

The length and width of the blade are two important considerations when selecting a band saw blade. The length should be measured from one tip to another, including any allowance needed from sharpening or installation. Generally, blades measure between 8″ and 12″ in length. The width should be selected based on the type of material being cut; thinner blades are great for small curves and tight corners while wider blades are better suited to perform heavy-duty work such as ripping through thicker materials such as hardwoods or metals.

Another important factor when shopping for band saw blades is tooth set – which has an effect on both smoothness and speed of a cut – as well as tooth shape and amount per inch (TPI). Tooth set describes how far apart each individual tooth is set away from one another; this affects how much force is required to drive a cut into a material and affects how thick it can be while still providing a smooth finish. Tooth shape refers to whether each individual tooth maintains an even angle body throughout its profile or changes slightly near its tip; this affects cutting speed by optimizing chip clearance at higher speeds. Finally TPI has an effect on how fine or coarse a cut will be; higher numbers mean lower feed rates but finer finishes overall.

Purpose of the Buying Guide

For anyone who is researching the best band saw blade to buy in 2023, this complete buying guide will provide helpful insight. Different blades are available for specific purposes and some are better than others in certain projects.

Blades can differ in type, size, profile, tensioning device, set and coating – each of which have significantly different properties and therefore warrant thorough consideration when selecting the one most appropriate for your specific application. Additionally, it’s important to understand how different types of steel relate to blade longevity and performance. This guide outlines all the key points so that you can determine the best band saw blade for your needs.

Factors to Consider when Choosing a Band Saw Blade

Choosing the right band saw blade for your project can be a difficult task, especially if you’re new to working with band saws. To help you make the right decision when shopping for a band saw blade, here are the most important factors to take into account:

- Blade Length and Width: The length and width of your blade will determine how effective it is on specific materials, so it’s important to choose a blade that is the right size for your project. Generally, blades come in lengths from 1/2″ to 1-1/4″. Additionally, blades usually range from 0.025″ – 0.063″ in thickness. If you are not sure which size is best for you, consult your manufacturer’s guide or user manual beforehand.

- Teeth per Inch (TPI): The teeth-per-inch count can range from 10 TPI up to 24 TPI. It will determine how quickly and accurately the saw can cut through different material types such as wood, plastic or metal – fewer teeth tend to provide faster cutting while more teeth offer improved accuracy and smoother cuts.

- Blade Material: Band saw blades typically come with either a carbon steel or bi-metal construction; carbon steel blades are very cost-effective but may require frequent sharpening, while bi-metal blades provide greater durability as well as longer lasting sharpness but tend to be more expensive than carbon steel blades.

By taking these three factors into consideration when deciding on which blade to buy, you can ensure that you’ll get the one best suited for your project!

Tooth Configuration

The tooth configuration of a band saw blade refers to the pattern and combination of various sizes, shapes, and angles of teeth along the length of the blade. The correct tooth configuration is determined based on the type of material being cut and the desired finish. Each saw manufacturer recommends the right tooth configuration for its machine, but it is usually best to start with a general purpose blade and then switch to other configurations as needed.

Common sizes range from 1/4” (6mm) for light-duty hobby saws up to 1-1/4” (31.8mm) for large commercial machines. As a general rule, thicker blades provide more strength when cutting thick or hard materials while thinner blades can be used on thin or soft materials without overstressing the machine. The number of individual teeth on a given blade can vary greatly, depending on the type and size of material being cut.

One advantage to band saw blades is that they can be customized by changing their tooth configurations in order to optimize performance for a particular application. Teeth come in two basic shapes: hook (or positive) and skip (or negative). Hook-style teeth are great for cutting through harder materials such as cold rolled steel, cast iron, aluminum extrusions, and stainless steel pipes; while skip style work better for softer materials such as aluminum sheet stock and plastics like ABS or PVC pipe. Blade tooth configurations also come in 3 separate profiles – flat top grind (FTG), wavy set (WS), or raker set (RS). Depending on your application’s needs one may be better than another.

Choosing the right tooth configuration depends largely on your particular sawing needs but whichever you choose make sure it fits your specific saw correctly so you get optimal performance out of each cut you make!

Blade Material

One of the key considerations when shopping for a band saw blade is the material from which it is constructed. Different materials are available, each with its own advantages and disadvantages; however, blades can be generally divided into two categories–carbon or bi-metal.

- Carbon blades–These are the most common type of band saw blade and are typically made from a spring steel alloy that has been hardened and tempered. Carbon blades tend to be less expensive than their bi-metal counterparts, but they may not last as long due to their softer construction. Additionally, they may require more frequent sharpening.

- Bi-metal blades–These are made by bonding a high-speed steel cutting edge (HSS) onto an alloy backing strip. This makes them more durable and able to resist breakage and wear better than pure carbon blades. They also stay sharper longer and typically require less frequent sharpening compared to carbon blades. However, they come with a higher price tag than carbon blades due to their more complex construction methods.

Blade Thickness

When choosing the right band saw blade for your needs, you must consider the blade’s thickness. The thickness of the band saw blade will determine how easily it can flex around curves, its resistance to vibration, and its cutting speed. A thicker blade will require more power, but it will also give you a better finish while being able to cut thicker materials with less vibration.

The different bands saw blades come in various sizes from ¼” (6 mm) to 1 ½” (38 mm). Smaller saws usually use blades that are about ¼ inch (6 mm) thick and larger saws commonly use blades that are about 1 inch (25 mm) thick. If a blade is too thick for a particular machine, it may not be able to reach full track speed or achieve maximum power.

When selecting a band saw blade, it is important to consider the material you are cutting as well as your desired cutting speed and accuracy. For example:

- Thinner blades excel at making intricate and delicate cuts on hardwoods while thicker blades could be used for rough cuts on metals such as aluminum or brass.

- Thinner blades are best suited for slower cuts while thicker ones are ideal for faster cuts.

Blade Width

When choosing a band saw blade for your particular project, blade width is one of the most important considerations. A blade that is either too wide or too narrow will result in a less than ideal cut, and can damage the saw itself. Here are some of the common blades widths available:

- 1/8-inch blades are the most popular size and work best with thin plastic or metal materials. These blades typically have 16 teeth per inch (TPI) and are great for making intricate cuts or small curves.

- 3/16-inch blades used in combination with 8 TPI make a much better choice when cutting thicker material such as lumber to make joints.

- 1/4-inch blades are stronger and more suitable for use on larger pieces of wood, especially when making rounded shapes. These blades usually have 14 TPI, but can be modified for even bigger tasks by increasing tooth size up to 24 TPI.

- Half Inch compact blade style has been gaining popularity due to its ability to deliver fast, straight cuts without significant effort on weaker materials like plywood or aluminum sheeting without sacrificing accuracy or causing harm to the saw itself.

Tension of the Blade

The tension of the band saw blade is extremely important to ensure a safe and successful cut. The tension must be maintained at a suitable amount for your particular saw, as too little tension will cause slippage while too much tension can cause the blade to snap. Generally speaking, it is beneficial to start with the recommended tension of your saw then make minor adjustments based on desired results.

Depending on the type of blade used in your band saw and its specific characteristics, the recommended setting should be noticeably marked on the frame with either an indicator or numerical value. Band saw blades can range anywhere from ⅛” to ¾” in width and usually range from 10 TPI up to 24 TPI (teeth per inch). To properly set your blade tension, start by increasing or decreasing it in increments of 5 pounds until you reach your desired pressure point.

Checking for proper tension is easy; using a feeler gauge placed between two teeth should press approximately 0.008-0.014” into a ⅛” thick blade when full conditioned pressure is applied for those 2 inches of teeth contact point. If you have any doubts about what setting works best for you, consult the owner’s manual of your band saw or talk to knowledgeable representatives who will usually have the answers you need!

Photo Source: finewoodworking.com

Cleaning and Lubrication

Cleaning and lubrication are two of the most overlooked but important aspects of maintaining your band saw blades. Keeping your blades free from dust, grime, residue and other debris will help extend their life and make them more efficient.

For best results, clean your blades after every cut to prevent buildup of debris. Use a cloth or brush to remove the dust and residue, then lubricate them with a vegetable or mineral oil. Regularly inspecting and cleaning the blade guides is also essential for good performance. You may need to adjust or replace the guides periodically to prevent warping or excessive vibration of the blades.

Proper Storage

For most DIYers, band saw blades are an essential tool for completing projects. However, the performance of their band saw blade heavily depends on their maintenance and proper storage. Certain tips needs to be kept in mind for storing the blades properly:

- Store your blades in a waterproof container when not in use. It is also recommended to place a piece of cardboard or paper between each blade to prevent scratches or any worst problems.

- Never store the blade outdoors or in areas with extreme temperatures as it might lead to its rusting or warping due to fluctuations in temperature.

- Also avoid storing the blade near chemicals such as those found in lubricants, motor oil, gasoline and paint thinners since they can corrode metal surfaces.

- Inspect your band saw blades before and after each use for damage such as nicks and grooves before storing them again away from dust, dirt, and moisture.

Keep these basic steps in mind when storing your band saw blade for better performance and greater longevity during all your projects!

Blade Tension Maintenance

One of the most important features of a band saw blade is tension maintenance. Properly maintaining tension is essential to the longevity of the blade and its cut quality. Blade tension should be checked at least once per week, or after any cutting operation that places increased strain on the machine. The general rule for checking blade tension is that if you can bend the band saw blade by more than one inch when pushing down in the center of the bottom pulley, then it’s too loose and needs to be tightened. If it doesn’t move more than one inch, then it should be good for your current task.

The way in which you should adjust your blade tension will depend on your specific machine. Most machines require you to loosen all screws at once, then adjust them till your desired level is reached. Some machines have a threaded rod that must be adjusted in order to change or maintain proper tension levels. It’s important to remember that in general, under-tensioning is better than over-tensioning as increased stress can cause premature aging of the components and reduce accuracy and performance over time. If blades are too tight they may increase noise levels as well as vibration throughout sensitive areas of your machine such as around bearings, table surfaces and seals.

Make sure to refer to your saw manual or contact the manufacturer’s support staff if you’re unsure on how to check and/or adjust your blade tension properly.

Conclusion

The choice of the best band saw blade should be influenced by the type of material you will be using it for, as well as your desired results. Blade tooth settings, gullet size, and tooth pattern can also contribute to the quality and performance. However, all these characteristics are stated in the blade’s data-sheet. Seeing as every user has different needs and wants, it is important to consider all the options available before buying a blade.

After a thorough review of all the above models, we conclude that our top pick is the Lennox Woodmaster Band Saw Blade due to its superior durability and superior cutting power. With customizable settings like tooth count, thicknesses and height, this band saw blade provides great value for your money.

Final Thoughts and Recommendations

When selecting the best band saw blade for your project, there are several important criteria to consider. The material you’re cutting should be matched with the tooth design on the blade so that it performs optimally. The width of the cut should also be taken into account and you may need to adjust the tension on your bandsaw if using a wider or thinner blade than usual. Additionally, you will want to select blades with a suitable number of teeth per inch (TPI) and with quality construction to ensure they will last through multiple projects.

We have reviewed some of the top band saw blades currently available on the market in order to help guide your decisions. When possible, purchase multiple blades so that you can get through various materials without dulling one blade too quickly. Regular sharpening of your blades is also recommended, as this will help maintain precision in your cuts and extend the lifetime of each blade.

Finally, it is important to put safety first when operating any power tool such as a bandsaw and ensure that all guards and protection plates are securely in place. Wear proper eye protection and other appropriate safety gear whenever necessary for maximum safety when working with a band saw environment.

FAQ’s

What is the best saw blade to use on composite decking?

The best saw blade to use on composite decking is a fine-toothed, carbide-tipped cross-cutting saw blade.

What jig saw blade to use on composite decking?

A jig saw blade with a fine-tooth, carbide-tipped design is recommended for cutting composite decking.

Can you cut composite decking with a regular blade?

Composite decking can be cut with a regular blade, but it will be more challenging and result in a rougher cut. Using a specialized saw blade designed for composite decking is recommended.

How do you cut composite decking material?

Composite decking can be cut with a circular saw, miter saw, or jigsaw using a fine-toothed, carbide-tipped saw blade. Make sure to secure the decking material firmly before cutting.

Can you use a wood saw to cut composite decking?

It is possible to use a wood saw to cut composite decking, but it is not recommended as it will result in a rough, uneven cut. It is better to use a saw blade specifically designed for cutting composite decking.

What should you not use on a composite deck?

Avoid using abrasive cleaners, steel wool, or a pressure washer on a composite deck as they can damage the surface.

What is the best saw blade for Timbertech?

The best saw blade for Timbertech composite decking is a fine-toothed, carbide-tipped cross-cutting saw blade.

Which saw blade makes the smoothest cut?

A fine-toothed, carbide-tipped saw blade makes the smoothest cut on composite decking.

How many teeth on composite deck saw blade?

Composite deck saw blades typically have between 40 and 80 teeth. The number of teeth will impact the speed and smoothness of the cut.

What is a 60 tooth saw blade good for?

A 60 tooth saw blade is good for making precise cuts in composite decking material. It is recommended for cross-cutting or ripping composite decking boards.

Michael Lilli is the author and CEO of sawbladetown.com and Informative Website. With over 10 years of experience in the saw blade industry, Michael has become a leading expert in the field. He is dedicated to helping professionals and hobbyists alike find the perfect saw blade for their projects. Through his informative website and writing, Michael shares his knowledge and expertise on everything from saw blade anatomy to advanced techniques and safety precautions. His passion for saw blades and commitment to helping others has made him a trusted resource in the industry.