Struggling to find the best circular saw blade for plywood? You’re not alone! With so many options available, it can be difficult to decide which blade is right for your project. Our complete buying guide will help you choose the perfect blade to fit your needs in 2023.

Best circular saw blade for plywood 2023

- DEWALT DWA171424 Saw Blade(Editor’s Pick)

- ENERTWIST Diamond Saw Blades (Best Overall)

- Freud Ultimate Melamine Blade(Budget friendly)

- DEWALT DWA1714 60 Saw Blade

- Freud D0740A Finishing Saw Blade

- OSB Plywood Cutting Saw Blade

- Freud Finish Cordless Trim Saw Blade

1) DEWALT DWA171424 Saw Blade

DEWALT DWA171424 Saw Blades are durable and efficient due to their careful blend of high-quality materials. This blade is easy to use and precise, measuring 8.5 x 0.5 x 9.75 inches and weighs 0.57 pounds.

Precision Fundamental

This saw blade has 24 teeth for smooth, accurate cuts that exceed the highest requirements. Its revolutionary design ensures a clean cut regardless of skill level. DEWALT is known for quality and performance, and this saw blade reflects that.

Expert Thin Kerf Design

Its narrow kerf design makes the DEWALT DWA171424 Saw Blade stand out. This innovative innovation reduces material removal with each cut, resulting in smooth, precise cuts. This feature is revolutionary for woodworkers, reducing splintering and other damage.

The Power of Premium Blends

The DEWALT DWA171424 Saw Blade is made of a strong, durable combination. This material is great for cutting tough materials easily. Its wood compatibility makes it ideal for many woodworking applications.

Conclusion

Finally, the DEWALT DWA171424 Saw Blade is a precision tool that performs well and is accurate. The mix material, narrow kerf design, and wood compatibility make it the best choice for experts and DIYers. This outstanding saw blade will improve your woodworking game and make every cut count. Don’t lower yourself when brilliance is possible.

Must Read – Best chain saw blade

DEWALT DWA171424 Saw Blade First Hand Review Video

Video Source: Honey Izzat Butt

Pros:

- Thin kerf design for smooth cuts

- Made with durable blend material

- Compatible with wood

- Precise and efficient cutting capabilities

- 24 teeth for optimal cutting performance

CORE FEATURE

| specifications | Thin kerf design for smooth cuts |

| Material | Blend |

| Brand | DEWALT |

| Item Dimensions LxWxH | 8.5 x 0.5 x 9.75 inches |

| Color | Multi |

| Number of Teeth | 24 |

| Style | New |

| Compatible Material | Wood |

2) ENERTWIST Diamond Saw Blades

These extraordinary blades’ structure is their heart. Their high-speed steel blades are strong and durable, delivering a blade that lasts. When precision cuts are needed, these saw blades won’t disappoint professionals or DIYers.

Precision Redefined

ENERTWIST Diamond Saw Blades revolutionise metal cutting precision with 24-tooth design. These blades provide you the control and accuracy needed for a beautiful finish on concrete, brick, or tile. ENERTWIST eliminates rough edges and uneven cuts, making your products appear great.

Best Versatility

The 4PCS ENERTWIST Diamond Saw Blades are versatile. They easily adjust to different cutting instruments, improving compatibility. These blades are suitable for home renovation and professional construction.

ENERTWIST Diamond Saw Blade Science

The combination of high-speed steel, tungsten carbide, and diamond makes ENERTWIST Diamond Saw Blades magical. These blades stand out due to their legendary attributes.

High-Speed Steel

High-speed steel gives these blades strength and durability. It keeps your blade sharp and reliable after many uses, saving you time and money.

Tungsten Carbide

Tungsten carbide, another essential substance, strengthens and precisions. It makes the blade slice through metal like a hot knife through butter.

Diamond Power The diamond, the centrepiece of this outfit, enhances precision. ENERTWIST Diamond Saw Blades are a valuable instrument because of their extreme hardness.

Conclusion: Superior

Overall, ENERTWIST Diamond Saw Blades are the best metal cutting tools. They easily handle the toughest tasks thanks to their high-speed steel, tungsten carbide, and diamond structure. The 24 teeth provide precision, while the 0.07-inch thickness adds variety.

You’re investing in metal cutting success with ENERTWIST Diamond Saw Blades. Choose ENERTWIST for superior outcomes. Increase your metal cutting skills today!

Must Read – Best chop saw blade for metal

ENERTWIST Diamond Saw Blades First Hand Review Video

Video Source: THE 6 BEST

Pros:

- Made with high-speed steel, tungsten carbide, and diamond materials

- 24 teeth for optimal cutting performance

- Versatile and can be used for a wide range of cutting applications

- 0.07-inch thickness for precision and control

- Durable and long-lasting, even when used for tough jobs

CORE FEATURE

| Product Dimensions : | 4.5 x 0.07 x 4.5 inches; 12.31 Ounces |

| Material | High Speed Steel, Tungsten Carbide, Diamond |

| Brand | ENERTWIST |

| Item Dimensions LxWxH | 4.5 x 0.07 x 4.5 inches |

| Color | Black, Silver |

| Number of Teeth | 24 |

| Style | 4-1/2″ 4PCS |

3) Freud Ultimate Melamine Blade

More than Function: The Freud Ultimate Melamine Blade’s vibrant colours enhance your instruments.

This blade’s 48 teeth cut precisely and hard. With these teeth, every cut is smooth and long-lasting.

Perma-Shield: Sharpness Care

Perma-Shield cools the Freud Ultimate Melamine Blade. This maintains blade sharpness. This reduces work interruptions and improves outcomes.

Champion Lightweight: Move Easily

This 0.15-pound blade is light. This lightweight construction simplifies intricate cuts. The Freud Ultimate Melamine Blade empowers.

Versatility: Great Engineering

This blade slices engineered wood well, demonstrating adaptability. Freud Ultimate Melamine Blade slices melamine, wood, and other tough materials. The ideal modern carpenter tool.

Melamine Cutting Precision

Your precision partner is Freud Ultimate Melamine Blade. This high-quality saw blade cuts melamine and other hard materials cleanly and accurately. Analyse its unique traits.

Excellent Blend: Unmatched Durability

The Freud Ultimate Melamine Blade’s secret weapon is mix. It cuts strong materials easily due to its hardness. Melamine eliminates chipping and splintering.

This blade cuts precisely with 48 perfectly honed teeth. Melamine and other difficult materials are sliced precisely by them. This blade’s 6.3-inch cutting diameter suits many cutting operations.

In conclusion: Freud Ultimate Melamine Blade Precision

Last, the Freud Ultimate Melamine Blade is unmatched in precision and performance. Its combined composition and 48 teeth easily overcame difficult materials. Its 6.3-inch cutting diameter and professional-grade quality make it ideal for anyone seeking a durable, efficient, and excellent saw blade. Improve your precision and craftsmanship with the Freud Ultimate Melamine Blade.

Must Read – Best circular saw blade

Freud Ultimate Melamine Blade First Hand Review Video

Video Source: WoodWorkWeb

Pros:

- Made with a durable blend material

- 48 teeth for optimal cutting performance

- 6.3-inch cutting diameter for versatility

- Minimizes chipping and splintering

- Professional-grade quality for precision and efficiency

CORE FEATURE

| Material | Blend |

| Brand | Freud |

| Item Dimensions LxWxH | 6.25 x 0.82 x 0.51 inches |

| Color | Multicolor |

| Number of Teeth | 48 |

| Item Weight | 0.15 Pounds |

| Part Number | LU79R006M20 |

| Item Weight | 2.4 ounces |

| Product Dimensions | 6.25 x 0.82 x 0.51 inches |

4) DEWALT DWA1714 60 Saw Blade

The DWA1714 60 Saw Blade from DEWALT shows their dedication to quality. DEWALT is trusted by professionals and DIYers for its tool manufacturing competence.

Compact and Lightweight

The compact and lightweight DEWALT DWA1714 60 Saw Blade is 8.5 x 0.5 x 9.75 inches and weighs 0.56 pounds. This makes it excellent for a variety of cutting applications that require manoeuvrability.

Best Precision: 60 Teeth Advantage

The 60 teeth of this saw blade make it special. These precision-engineered teeth ensure precise cuts for your woodworking tasks.

New Style Design: Improved Performance and Durability

The DEWALT DWA1714 60 Saw Blade’s innovative style improves performance and durability. This revolutionary design improves the blade’s beauty and functionality. It shows DEWALT’s dedication to tool innovation.

The Benefit of Thin Kerf

The narrow kerf of the DEWALT DWA1714 60 Saw Blade is notable. This innovative function reduces material removal during cuts, making them smoother and more precise. This is essential in woodworking because it reduces splintering and other damage.

Using Blend Material Power

The high-quality mix material of this saw blade is also appealing. Its resilience and strength make this material excellent for cutting through even the toughest materials. When paired with 60 teeth, it ensures clean and accurate cuts for maximum woodworking accuracy and control.

Conclusion: Your Precision Gateway

The DEWALT DWA1714 60 Saw Blade is a gateway to woodworking precision, efficiency, and brilliance. Its mix material, low kerf design, and 60 teeth make it the best cutting tool for reliability and efficiency. The DEWALT DWA1714 60 Saw Blade combines accuracy and workmanship to elevate your woodworking projects.

Must Read – Best circular saw blade for cutting doors

DEWALT DWA1714 60 Saw Blade First Hand Review Video

Video Source: Tool Review Zone

Pros:

- Thin kerf design for smooth cuts

- Made with durable blend material

- 60 teeth for precise and clean cuts

- Compatible with wood

- Provides accuracy and control for woodworking projects

CORE FEATURE

| specifications | Thin kerf design for smooth cuts |

| Material | Blend |

| Brand | DEWALT |

| Item Dimensions LxWxH | 8.5 x 0.5 x 9.75 inches |

| Color | Multi |

| Number of Teeth | 60 |

| Style | New |

| Item Weight | 0.56 Pounds |

| Part Number | DWA171460 |

| Item Weight | 9 ounces |

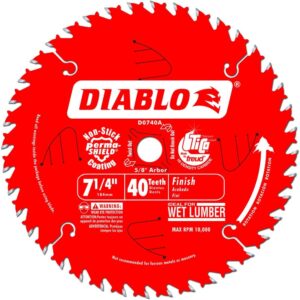

5) Freud D0740A Finishing Saw Blade

The Freud D0740A Finishing Saw Blade is made of high-quality carbide, ensuring durability and longevity. Freud, known for its cutting-edge instruments, excels again with this saw blade.

Ideal Dimensions

This 7.25 x 7.25 x 0.31-inch saw blade is ideal for many woodworking tasks. Its bright red colour adds style and helps you find it among workshop tools.

Precision in Every Tooth

This blade’s 40 teeth ensure a smooth, clean cut, making it ideal for finishing work. Its precision cutting ensures great woodworking creations.

Lightweight and Portable

At 0.3 pounds, the Freud D0740A Finishing Saw Blade is remarkably light for its sturdy features. This portability makes it easy to use for woodworking projects.

Unmatched Results

The Freud D0740A Finishing Saw Blade is the perfect finishing tool for individuals who want reliability and efficiency. This blade will exceed your cutting expectations with its robust carbide manufacturing, ergonomic design, and effective 40-tooth configuration.

Precise Wood Cutting

Precision is key to woodworking success. The Freud D0740A Finishing Saw Blade elevates wood cutting with its advanced features.

A Carbide Advantage

Carbide makes the Freud D0740A Finishing Saw Blade stand out. Carbide, known for its hardness and wear resistance, is suitable for woodworking. This excellent substance allows the saw blade to cut precisely.

Power of 40 Teeth

The Freud D0740A Finishing Saw Blade has 40 teeth, another notable feature. These teeth are designed for accurate, clean cuts. This level of precision offers faultless outcomes every time, changing woodworking jobs.

Versatile Cutting

This saw blade is versatile and suited for many cutting tasks due to its 7.25-inch cutting diameter. Freud D0740A Finishing Saw Blade is your reliable partner for intricate patterns and larger tasks.

Finally, the Freud D0740A Finishing Saw Blade is a woodworking partner with excellent performance and precision. Its carbide structure and 40 teeth allow it to cut wood with precision and control for perfect woodworking projects. Improve your woodworking with this saw blade.

Must Read – Best combination table saw blade

Freud D0740A Finishing Saw Blade First Hand Review Video

Video Source: Robert Dailey – Dailey Woodworks

Pros:

- Made with durable carbide material

- 40 teeth for optimal cutting performance

- 7.25-inch cutting diameter for versatility

- Provides accuracy and control for woodworking projects

- Portable and easy to use

CORE FEATURE

| specifications | Country Of Origin: China |

| Material | Carbide |

| Brand | Freud |

| Item Dimensions LxWxH | 7.25 x 7.25 x 0.31 inches |

| Color | Red |

| Number of Teeth | 40 |

| Style | Portable |

| Item Weight | 0.3 Pounds |

| Part Number | D0740A |

6) OSB Plywood Cutting Saw Blade

The silver-colored OA-BRES OSB Plywood Cutting Saw Blade has 150 teeth. These teeth are precision-engineered for flawless cutting.

Plywood cutting, accurate cuts, engineered wood materials

Flexible Performance

This circular saw blade is versatile. Its engineered wood compatibility makes it essential for any workshop. It cuts even the hardest tasks easily.

Engineered wood, versatile addition, cutting jobs

Pro-Level Performance for All

This saw blade will please professionals and DIYers alike. Its durability and reliability make it a worthwhile investment for plywood and engineered wood workers.

Professional contractor, DIYer, dependable performance

The Ultimate OSB Plywood Friend

The appropriate saw blade is essential for cutting OSB plywood and other materials. The OA-BRES OSB Plywood Cutting Saw Blade is a top choice for precision and performance. Its composition and 150 teeth allow precise cuts in OSB plywood and other engineered wood components.

Top-tier OSB plywood, cutting performance

Power of Plywood

Plywood makes the OSB Plywood Cutting Saw Blade stand out. Plywood is good for cutting OSB plywood due to its durability. This composition allows the saw blade to cut more precisely than other blades.

Durable plywood material can withstand wear and tear.

The Teeth Matter

Another appealing characteristic of the OSB Plywood Cutting Saw Blade is its 150 teeth. These teeth make it so effective in cutting. They guarantee faultless results every time the saw blade cuts OSB plywood and engineered wood products precisely and cleanly. Its round form makes it versatile for a variety of cutting applications.

Optimal cutting performance, circular style, cutting applications

In conclusion, the OA-BRES OSB Plywood Cutting Saw Blade is the best instrument for precision and performance. With its plywood construction and 150 teeth, it slices OSB plywood and other engineered woods easily. This accuracy and control are essential for any woodworking operations.

Woodworking tasks, precision, accuracy, control

Must Read – Best concrete saw blade

OSB Plywood Cutting Saw Blade First Hand Review Video

Video Source: 731 Woodworks

Pros:

- Made with durable plywood material

- 150 teeth for optimal cutting performance

- Compatible with engineered wood and plastic materials

- Circular style for versatility

- Provides accuracy and control for woodworking projects

CORE FEATURE

| Package Dimensions : | 4.84 x 4.57 x 0.35 inches; 7.05 Ounces |

| Country of Origin : | China |

| Material | Plywood |

| Brand | OA-BRES |

| Color | Silver |

| Number of Teeth | 150 |

| Style | Circular |

| Compatible Material | Engineered Wood, Plastic |

7) Freud Finish Cordless Trim Saw Blade

Strong Cutting Tool, Precision Woodworking, Carbide Saw Blade

Power of 36 Teeth

The Freud Finish Cordless Trim Saw Blade cuts engineered wood and metal smoothly with 36 teeth. These teeth are precise, not just quantity. Each tooth ensures clean, accurate cuts, essential for woodworking.

36 Tooth Saw Blade, Clean Cuts, Accurate Woodworking

Get rid of buildup

This blade’s nonstick design minimises buildup and makes cutting smoother. No more annoying blade cleaning breaks mid-project. With the Freud Finish Cordless Trim Saw Blade, you may craft uninterrupted.

Nonstick Saw Blade, Smooth Cutting, Build-Up Prevention

Ultimate Choice

The Freud Finish Cordless Trim Saw Blade is a reliable and efficient saw blade for woodworkers. It’s an investment in precision, performance, and excellence, not just a tool.

This blade’s carbide structure and 36 teeth make it ideal for difficult materials. Avoid rough edges and uneven cutting. The Freud Finish Cordless Trim Saw Blade gives your projects a craftsman-like look.

Conclusion

Woodworking saw blades offer high-performance cutting and precision craftsmanship.

In woodworking, precision matters. The Freud Finish Cordless Trim Saw Blade unlocks craftsman potential. Its 36 teeth, carbide material, and nonstick design make it the best for clean, precise cuts on many materials. Upgrade your tools today to see how quality and precision may improve your woodworking tasks.

Quality Saw Blade, Precision Woodwork, Tool Upgrade

Use the Freud Finish Cordless Trim Saw Blade to improve your woodworking skills. Craft with precision to eliminate substandard cuts and achieve perfection.

Must Read – Best dado blade for table saw

Freud Finish Cordless Trim Saw Blade First Hand Review Video

Video Source: dk builds

Pros:

- Durable and long-lasting product

- Meets customer requirements for a reliable and efficient saw blade

- Manufactured in Italy with high-quality standards

- Carbide material for strength and durability

- 36 teeth for optimal cutting performance

CORE FEATURE

| specifications | Manufactured in Italy |

| Material | Carbide |

| Brand | Freud |

| Item Dimensions LxWxH | 5.4 x 5.4 x 0.1 inches |

| Color | Multi |

| Number of Teeth | 36 |

| Style | Nonstick |

| Item Weight | 9.07 Grams |

| Part Number | D0536X |

Best circular saw blade for plywood 2023-Complete buying Guide

When it comes to completing your woodworking project, it’s important to choose the right tool for the job. A circular saw is an essential tool when it comes to cutting plywood. To get the best results from your saw, you need to make sure that you have a good quality saw blade that can handle the material that you’re working with.

The 2023 market is full of well-made circular saw blades specifically engineered for cutting plywood. To help you get started on your journey to finding the perfect blade for your project, we’ve put together this guide. It will cover all things related to circular saw blades— everything from identifying and selecting the right one for your projects to maintaining and sharpening a blade correctly— so you make the smartest cutting choices when dealing with plywood.

Photo Source: familyhandyman.com

Importance of having the right saw blade

Having the right saw blade is an important factor in ensuring that you make accurate cuts when working with plywood. Depending on the type of project you are working on, you may need either a circular saw or a table saw to cut the plywood to size. Regardless of which type of saw you decide to use, it is essential to use the right kind of saw blade for optimal performance.

Using the wrong kind of saw blade can not only produce inaccurate cuts but can also pose safety hazards. For example, using high-speed steel blades on soft materials such as plywood can cause them to overheat due to friction and make them very brittle, leading to breakage and possible injury if they shatter while in operation. Thus, it’s important that you know:

- Which types of blades are best suited for different materials

- How to properly sharpen your blades so that they last longer and stay sharp for cleaner cuts.

Purpose of the guide

Before you even think about making your purchase, it’s important to understand exactly what you need the saw blade for. Different blades are used for different reasons and in various contexts—they often even vary depending on the type of saw being used.

Not all circular saw blades are created equal, meaning there will be differences in the type of materials and cuts that each one can make. Equipping yourself with a little knowledge beforehand will go a long way in ensuring that you make the right decision for your particular application.

The purpose of this guide is to provide an overview of circular saw blades in general, so you understand what is available and how to make an informed choice when selecting one for plywood applications. Read on to find out more than just which blade makes the best cuts in plywood. You will learn basic facts about them, such as their types and features, as well as ways to care for them and how to keep them sharp over time.

Types of Circular Saw Blades

Circular saw blades are categorized according to their number of teeth, blade diameter, blade thickness and hook angle. The key factor in blade selection is the job you’re performing – using the wrong kind of blade could cause damage to your work piece. Here’s a rundown of the most common types of circular saw blades and what they’re used for:

- General Purpose: These blades have between 40-60 teeth and feature a 20-degree hook angle, making them suitable for a wide variety of materials including soft wood, hard wood, particle board, plywood and laminate.

- Rip-Cut Blades: When cutting long boards along the grain (rip cuts), you need a saw with more aggressive teeth that are spaced further apart. Rip blades have fewer teeth (typically around 24). They also have a larger hook angle (15°-20°) so that any binding pressure created by pushing your material through the blade is relieved.

- Crosscut Blades: Crosscutting requires many more teeth on your blade along with a smaller hook angle (usually 0° – 10°). Blades specifically designed for crosscutting generally come with 60 – 80+ teeth designed to create an incredibly smooth finish when working on hardwoods or other dense materials.

- Combination Blades: Combination blades feature both rip and crosscut tooth geometries on each side. This allows you to switch between rip and crosscut without having to swap out your blade. Combination blades come in different configurations depending on which one best suits your needs; look for those hot stamped “TCG” or “ATB,” which stand for “Triple Chip Grind” or “Alternate Top Bevel.”

Rip blade

A rip blade is perfect for cutting with the grain in plywood, hardboard and other sheet goods. It makes smooth, fast, clean cuts and can handle even pressure-treated lumber. The teeth on a rip blade have a straight-across or flat-top grind which helps with better dust extraction and reduced board burning.

It’s a good all-purpose tool for ripping or crosscutting pieces of plywood up to 1/2″ thick. This type of blade generally has between 18 and 24 teeth which makes it ideal for use in heavier duty applications such as framing lumber or any other woodworking project that requires precision cutting.

Cross-cut blade

A cross-cut blade is designed to produce a clean, square cut across the grain of the material. Commonly used on hard and soft woods, a cross-cut blade typically features a combination of alternating top bevel (ATB) and alternate top/face (ATAF) teeth configurations that are mounted onto the blade rim.

ATB teeth are angled high to create a curved cutting pattern with clean edges, while ATAF teeth have both top bevel and face design to deliver high performance stability. Cross-cut blades also tend to include some negative hook angles for tearing away fibers when cutting thick pieces of plywood. For maximum performance when cutting plywood, choose a dedicated cross-cut saw blade with 4-5 degree hook angles.

Combination blade

A combination blade is a great all-arounder for plywood. It uses a combination of teeth and raker teeth, and is especially effective when cutting soft materials including pine, fir and plywood. The number of teeth on a combo blade ranges from 18 to 80, but the most common sizes are 40-50 Teeth per Inch.

Additionally, this type of saw blade can be used for cross cutting and rip cuts in plywood for clean edges that don’t require sanding. Combination blades typically have round flanges or “bot rests,” which makes them well suited to handheld or circular saws as well as router tables.

Factors to consider when choosing a saw blade for plywood

When choosing a saw blade for plywood, there are several factors that should be taken into consideration. These include the diameter of the circumference (inches), the number of teeth, the kerf size, and the type of coating and material used.

Diameter: When selecting a saw blade for plywood, one must first consider the actual diameter of the circle cut out by the saw blade. A larger diameter will make larger cuts whereas a smaller diameter will allow for more accurate results when cutting intricate shapes or curves while still allowing wooden pieces to be cut quickly and accurately. A wide range of diameters means there is likely one that’s right for any job.

Number of teeth: The next factor to consider is how many teeth you need on your saw blade. More teeth usually leads to smoother finish on plywood cuts but also leads to slower cutting speeds and requires less pressure compared with blades with fewer teeth – something that is useful when trimming fine details down without damaging softwood materials or surrounding furniture surfaces. For common uses such as rip cuts, comprising several rapidly-traveling straight lines through wood grain, blades with larger numbers of teeth are suitable as they produce greater accuracy, in addition to creating a polished look which can be very attractive in some applications.

Kerf size: The ‘kerf’ refers to the width – depth – of each cut that your saw blade produces in wood when used correctly; it’s also affected by RPM speed settings at different angles from vertical flat surfaces being worked upon. Kerfs vary depending on what type of material is being cut; softer woods like pine require narrower kerfs than dense hardwoods such as oak in order to provide better efficiency during operations while avoiding thin slices pulled up during operations. Having said this – many commercial-grade blades provide consistent and appropriate kerfs regardless which grade it’s meant for!

Material/Coating: Another important variable is which type material or coating your saw blade has been made with; due to its construction directly affecting durability long-term usage (lifetime) as well as precision cutting edges right through thick wooden planks at all times without heating up excessively rapidly or becoming dull quickly afterward! High-tensile steel alloys often feature between multiple layers joined together securely so they don’t warp from intense stress added regularly whilst remaining reliable dry-working conditions even after continuous use over extended periods providing both cost effectiveness alongside versatile performance results!

Teeth per inch (TPI)

When selecting the right circular saw blade for a plywood project, one of the most important characteristics to consider is the teeth per inch (TPI). The more teeth there are on a blade, the smoother and cleaner it will cut. Generally speaking, the higher the TPI count on a plywood saw blade, the better. Blades with lower TPI counts may cause chipping and splintering on edges and corners. Teeth that are too pointy can also leave burn marks or “wave marks” on plywood’s surface.

When looking for plywood saw blades specifically designed for cutting softwoods or hardwoods, look for blades labeled as “plywood blades” or “multi-purpose blades”. These are typically composed of high-grade carbide tips that reduce wear and tear, ensuring longer performance and longer working life to your circular saw blade. Most manufacturer’s standard carbide blades feature options from 24 TPI to 80 TPI in various sizes; however, there are some specialty brands featuring tooth counts up to 140 TPI.

If you plan on using your circular saw predominantly with thicker materials such as laminates, particle board or other pressure treated lumber products then a lower tooth count would be more efficient as these materials often require aggressive cuts with lots of chewing power rather than smooth clean cuts that produce less wear and tear on your circular saw blade’s teeth.

Blade Material

An important factor to consider when choosing the best circular saw blade for plywood is the material used to construct the blade. Different blades are made from different materials, and depending on its intended use, one material may be better suited than another.

- High-speed steel (HSS) blades are some of the most common and feature a lightweight design that makes them perfect for general cutting applications.

- Carbide-tipped blades feature teeth made from tungsten carbide for long lasting performance when cutting hardwoods and other dense materials.

- Ceramic-tipped blades are also available and look like a combination of HSS and carbide options. These blades offer superior durability, even at varying speeds while providing easy maneuverability in tight spaces or corners.

Blade Diameter

When you’re looking for a saw blade, the first thing you should take note of is the blade diameter. The diameter determines the size of material your saw can cut and also how fast it will spin. Generally, standard circular saw blades range from 4-7 inches in diameter, though some specialty blades may be as small as 2.75 inches or as large as 8 inches. For plywood projects, a 6-7 inch blade performs best and provides comfortable control when cutting curves.

Keep in mind that if your saw has an arbor that is too small to accommodate your desired blade size, you may need to purchase an adapter or additional arbor size chucks. It’s important to always check your manufacturer’s instructions before changing any components on your circular saw.

Kerf

The kerf, sometimes referred to as the cut width, is the thickness of the saw blade when measured from side to side. It is important to note that some blades may have different thicknesses depending on their purpose. Plywood cutting blades generally have a thinner kerf than those designed for cutting hardwoods or plastics.

When choosing a saw blade based on the kerf, consider your power source and type of plywood you will be cutting. Thicker blades require more power to make a cut and may cause binding if used with small motors or thin plywood. A thinner kerf will create a thinner cut but generally require less power and produce cleaner edges on thin materials.

How to use a Circular Saw Blade for Plywood

Using the right blade is key to creating smooth, accurate cuts with a circular saw. A good saw blade allows you to make clean, consistent cuts on plywood while minimizing tear-out and damage to the wood. To cut plywood with a circular saw, you need a carbide-tipped blade with around 24 teeth. Make sure the blade has an adequate number of teeth for the material – more teeth mean a smoother cut, so for plywood you want at least 24 teeth. The number of teeth also affects how fast a particular saw will cut; more teeth mean it will take longer but produce cleaner cuts.

To use your circular saw, first adjust its cutting depth so that it’s set about 1/4 inch (6 mm) less than the thickness of the plywood you’re cutting. This will allow for smoother cuts and prevent damaging the bottom layer of your plywood sheets. Before using the circular saw, be sure to secure your workpiece firmly to avoid damaging it or having an accident due to movement while cutting. When starting off with your circular saw blade, place it in contact with your material before powering up and apply gentle pressure until it begins to cut through the wood. Don’t push down on your workpiece too hard or you’ll create dents and marks along its edge – just steady pressure is enough to make clean and accurate cuts. As always when using power tools, wear all necessary safety gear such as protective eyewear and hearing protection when operating your saw.

Once you’re finished making all desired cuts on your plywood sheet(s), allow plenty time before handling them as they can be hot due from friction caused by contact from the rotating blades at high speeds which can sometimes reach roughly 7400 revolutions per minute (RPM). This wraps up our guide on how best to use a circular saw for cutting sheets of plywood safely!

Photo Source: sawsonskates.com

Safety precautions

It is essential to take safety precautions when utilizing a circular saw. Protective eyewear should be worn at all times and always put on long pants and closed-toed shoes. Be sure to maintain a firm grip and the right posture for cutting.

Lay the work material down on top of a sturdy surface, preferably one that is not softer than the material itself. Before beginning, you should also check your saw blade for any signs of damage or wear and replace it as needed. It is also important to make sure it is securely fixed, then double-check that the blade guard is down before turning it on.

Furthermore, when making a plunge cut ensure that you control the saw as it enters or exits the wood, as this can prevent kickbacks by minimizing contact with separate pieces of lumber simultaneously.

Conclusion

To conclude, it’s important to note that choosing the right circular saw blade will depend on your woodworking needs, the type of wood and project you are working on, as well as your budget. While all blades may look similar, they all have their differences. Reading reviews and recommendations online can save you time and money.

We believe that by considering each factor, studying blade construction materials, evaluating blade specifications and performance, deciding between a framing or plywood specific blade as well as comparing prices are all essential steps to making an informed purchasing decision. Armed with this background information we hope you will be able to pick the best circular saw blade for plywood in 2021.

FAQ’s

What circular saw blade is best for cutting plywood?

A circular saw blade with 40 to 60 teeth is best for cutting plywood.

How many teeth should a circular saw plywood blade have?

A circular saw blade for cutting plywood should have 40 to 60 teeth.

What is the best TPI for cutting plywood?

A TPI (teeth per inch) of 80 to 100 is best for cutting plywood.

What type of blade is best for circular saw?

A cross-cutting or fine-toothed blade is best for cutting plywood with a circular saw.

Which saw blade makes the smoothest cut?

A blade with a high TPI (80-100) and a smooth-toothed grind will make the smoothest cut.

Is more teeth on a circular saw blade better?

More teeth on a circular saw blade can produce a smoother cut, but it also depends on the TPI and tooth geometry.

What is the best tooth count for plywood?

The best tooth count for plywood is 40 to 60 teeth.

What is a 60 tooth saw blade used for?

A 60 tooth saw blade is used for cross-cutting and fine finish work, such as cutting plywood, MDF, and other softwood materials.

What is the best number of teeth for circular saw?

The best number of teeth for a circular saw blade depends on the material being cut and the desired finish, but a range of 40-60 teeth is ideal for cutting plywood.

What is a 120 tooth saw blade used for?

A 120 tooth saw blade is used for ultra-fine cross-cutting and finish work, such as cutting delicate or intricate patterns in wood or for achieving a highly polished edge.

Michael Lilli is the author and CEO of sawbladetown.com and Informative Website. With over 10 years of experience in the saw blade industry, Michael has become a leading expert in the field. He is dedicated to helping professionals and hobbyists alike find the perfect saw blade for their projects. Through his informative website and writing, Michael shares his knowledge and expertise on everything from saw blade anatomy to advanced techniques and safety precautions. His passion for saw blades and commitment to helping others has made him a trusted resource in the industry.