Do you need to make precise cuts with a table saw? Choosing the right blade is essential for successful woodworking projects. Finding the right blade that’s designed for your specific needs can be intimidating and overwhelming.

In this guide, we will provide you with essential information to make the best choice.

When it comes to woodworking, having the right saw blade can make all the difference when it comes to cutting results. You want a saw blade that is made from durable material, designed for your needs, and sharp enough to ensure clean and accurate cuts every time. In this guide, we’ll take a look at what types of saw blades are available and how you can choose the best table saw blade for your woodworking needs.

A saw blade is the circular disk with cutting edges that rotates on an arbor to make cuts in materials like wood. Saw blades are available in a range of sizes and made for different applications, and their quality varies depending on the manufacturer. Saw blades are measured by diameter as well as number of teeth, which affects their cutting speed and finish result; so choosing the right one is essential.

When it comes to choosing a table saw blade that’s right for you, there are three main factors you should consider: material type, number of teeth, and kerf width. Different materials have different requirements in terms of hardness and corrosion-resistance while the number of teeth determines the finish quality of cut surfaces; wider kerfs suit thicker material while narrower widths provide better precision in thinner stock lumber. There are also other features you may want to consider such as laser-cut designs on certain models as these provide improved accuracy due to their consistency in shape/size per tooth.

Explanation of the importance of choosing the right table saw blade for woodworking needs

Using the right table saw blade is essential in woodworking. The appropriate blade will ensure you get a clean cut and smooth finish. It can also help prolong the life of the saw, reduce tear-out, and minimize noise and vibration.

Table saw blades come in a variety of styles, including rip blades designed for cutting with the grain of wood; crosscut blades with more teeth for cutting across the grain; combination blades that feature both alternate top bevel (ATB) teeth for crosscutting and flat-top teeth for ripping; and specialty blades that feature special grinds such as wobble dado sets or nail-embedded fiberglass/resin blades.

The type of blade you need will depend on what type of wood you will be working with, as well as what type of cuts you plan on making. For example, if you are going to be cutting hardwoods like oak or maple, you should look for a blade that has carbide tips to provide maximum durability and support long-lasting performance. For softer woods like pine or birch, an all-purpose blade may suffice. Additionally, if you plan on making any miter or beveled cuts in your project, then an ATB type blade is best suited for those types of cuts.

Understanding the best types of tables saw blades is important because it can help save time and money by supplying better results than an incorrect blade choice might offer. Before buying a table saw blade, read through product reviews and consider purchasing from brands known to produce reliable products such as Freud Tools or Delta Power Tools who have good warranties on their products.

Brief overview of the key factors to consider when selecting a table saw blade

Choosing the right table saw blade for your woodworking projects can be a daunting task. To make an informed decision, it’s essential to understand some basic facts about saw blades and the factors that influence their performance. The following is a brief overview of the key factors to consider when selecting a table saw blade:

– Tooth size and configurations: Saw blades typically have anywhere from 14 to 80 teeth. The number of teeth affect how quickly and smoothly a saw will cut through material, as well as how much tear-out there will be.

– Blade kerf width: This refers to the width of the slot that the saw blade makes in a piece of material when cutting it. Generally, wider Kerf blades are recommended because they create a smoother cut than narrower ones.

– Hook angle: The hook angle is measured in degrees (°) and it determines how quickly a blade will cut into material while still producing clean cuts underneath. A higher hook angle provides more aggressive cutting power while also producing smoother cuts underneath due to less chip out.

– Plate thickness: The thickness of the plate on which the teeth are mounted is important because it affects both rigidity and accuracy of cut. Thicker plates on table saw blades provide greater stiffness, resulting in less vibration during operation and more precise cuts.

– Material hardness rating: Materials such as stainless steel, aluminum alloys, hardwood or softwood require different types of blades for successful cutting performance – harder metals require softer blades while softer woods need carbide tipped or diamond coated blades for longer life and cleaner cuts respectively.

By understanding these five key factors you can narrow down your choices when selecting an appropriate table saw blade for your application needs as well as help identify high quality products from lower quality ones – making sure you get optimal performance with every cut you make!

Understanding Table Saw Blade Basics

When selecting a table saw blade for your woodworking needs, it’s important to understand the basics of blades. There are three main types of table saw blades: rip, crosscut and combination blades. Each type serves a unique purpose and is designed for a different type of cutting task.

A rip blade has large, deep teeth that have a flat top and bottom with slightly curved sides and a narrow gullet between each tooth. The deep teeth cut across the grain of the wood and are designed for ripping long boards into smaller pieces. A crosscut blade has smaller teeth that are tapered with alternating bevels on the top and bottom. It is made specifically to cut across the grain of short pieces as well as along the grain when making thin strips. A combination blade incorporates features from both types and can be used in various woodworking applications when versatility is needed.

To determine what size saw blade you need, consider the thickness of your material and its hardness level (soft or hard woods). Smaller diameter blades help preserve thin materials by reducing vibration, but large diameter blades provide stronger cutting action to effortlessly cut through hardwoods like maple or walnut without stretching or splitting them apart like small diameter blades can do. You should also pay attention to carbide-tipped vs steel-backed options; carbide tips tend to wear better in harder materials but require more power to operate than steel options so they are more expensive upfront but last longer overall if you use them properly.

Anatomy of a table saw blade

Table saw blades are designed to function as the cutting edge of your woodworking projects, and they come in a wide range of styles and sizes. Knowing the anatomy of these blades and how to choose the right one is essential for successful woodworking.

The most important part of a table saw blade is its teeth, which are responsible for making cuts in the material that you are working with. The shape, number, and size of these teeth can vary greatly between blades. For instance, rip blades typically have fewer teeth than crosscut blades because the objective is to make a coarse cut quickly. Crosscut blades will typically have more teeth than rip blades for making finer cuts that may require precision accuracy.

In addition to tooth geometry, you’ll also want to consider table saw blade size when selecting one for your project. Table saws generally come in sizes ranging from 7 to 12 inches in diameter; larger blades generally result in more aggressive cuts due to their increased surface area but can be difficult to manage on smaller saw tables. Blades also come in different thicknesses; while thinner blades can result in better precision cuts, they tend not to last as long when performing tougher tasks like ripping through hardwoods or plywood sheets.

Once you’ve got the basics covered with regards to size and tooth geometry, it’s important to understand some of the other design features available on table saw blades that may help maximize performance depending on your project’s requirements. Carbide tipped teeth provide added durability for tearing through tough woods like oak or redwood; many also incorporate anti-vibration slots along their bodies which help improve cutting accuracy by reducing vibration from spinning too fast or wobbling out of line during wider rips. Additionally, look for advanced coatings like titanium nitride which may increase rust resistance or provide longer-lasting cutting edges over standard steel options without sacrificing much cost.

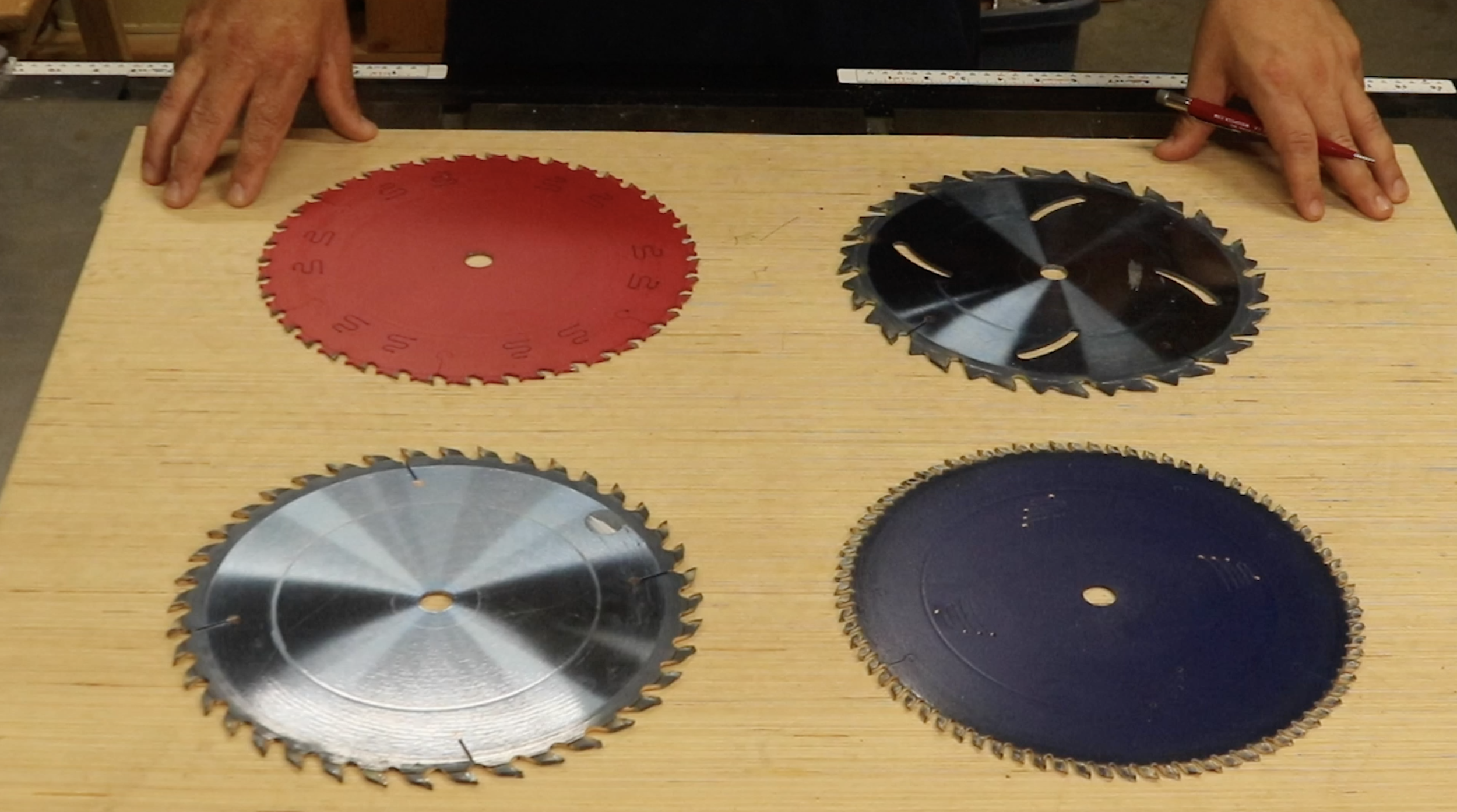

Different types of table saw blades

Table saw blades are name-checked in practically every woodworking project, but they aren’t all one-size-fits-all. Depending on your application, you may need to choose from a variety of blade types and sizes. Here are the most common types of table saw blades and how you can use them:

Crosscut Blade: A combination blade typically used for cutting across the grain of boards, these blades combine elements of rip and crosscut teeth allowing for a clean finish. The crosscut design creates a fine splinter free finish on both sides of the cut, making it ideal for cabinetmaking or milling tasks.

Ripping Blade: This type is designed exclusively for ripping wood along its grain line – like when you’re cutting custom parts from raw lumber or planning off mill ends. A ripping blade has large gullets between its teeth to carry away larger chunks of saw-dust generated by the wide supportive surface it provides over the top of the cut area.

Shaper Blades: These small diameter dado cutters are used to make decorative cuts and inlay work alike by creating straight lines along with round, arc-shaped curves using an adjustable table saw throat plate in combination with a dado set as skilled job that requires precision setting up/fixturing customization including trimming piece edges using “hinted” bearing bits used mostly in furniture/cabinet making & production industries.

A Plywood Blade: This type is specially designed to cut veneers without chipping or tearing because it uses an alternating beveled teeth configuration around its entirety to keep handling plywood softer materials easier due to being finer and thinner than standard solid wood projects.

Differences between blades for ripping and crosscutting

When it comes to table saw blades, there are a variety of styles and sizes to choose from. It’s important to understand the differences between them so you can make the best decision for your woodworking needs. The two main types of blades that are used for cutting wood on table saws are ripping blades and crosscut blades.

Ripping Blades: Ripping blades have a large number of teeth that are spaced wide apart, making them very effective for making long straight cuts (rips). They also produce less tear-out on the surface of the wood, which is ideal for cutting plywood or other materials that tend to splinter when cut by standard saw blades.

Crosscut Blades: Crosscut blades, on the other hand, have fewer teeth than ripping blades but they’re spaced closer together. These types of saw blades create smoother cuts with less splintering because they make finer incisions in the wood. Crosscutting is best used for precision cuts when a certain degree of accuracy is required or desired—such as when cutting hard or expensive woods.

It’s important to consider several factors when selecting a blade type such as tooth design, kerf width, plate thickness and speed ratings before choosing one for your specific project needs. Knowing what each blade is designed to do will help ensure that you get professional-quality results.

Factors to Consider When Choosing a Table Saw Blade

When shopping for a table saw blade, there are several things to consider in order to find the best blade for your particular woodworking needs. Blade manufacturers use various design features to make their products attractive to a wide range of woodworkers. The most important factors that you need to consider include:

- Tooth Design – The number and pattern of teeth can have a big impact on how well your saw does its job. Generally, higher tooth counts will deliver smoother cuts, while lower counts provide better performance on hardwoods and other tough materials. Look for blades with alternate top bevel (ATB) teeth or combinations such as triple-chip grind (TCG).

- Arbor Size – It’s important to choose a blade with an arbor size that matches the shaft of your saw’s motor, otherwise it won’t fit at all. Make sure you take measurements prior to purchasing your new blade. In some cases, accessories such as bushings may be needed in order to fit the blade onto the saw correctly.

- Plate Thickness – You should also consider the thickness of the plate when choosing a table saw blade. Thinner plates are lightweight and cost-effective but can get bent or damaged more easily than thicker blades that offer more durability and stability when cutting through dense materials such as hardwood or laminate flooring.

- Kerf Width – This refers to how wide a cut can be made by the saw blade, and it indicates how much material is removed during each pass with the saw. Choosing blades with thinner kerf will reduce overall waste because less material is taken away during each pass, but this requires more precision in terms of setup and alignment if you want smooth results every time. Thicker kerf blades cut faster due largely because they generate less heat than thin models do, meaning that they don’t need as much power from your motor in order attain high speeds quickly.

Type of cut required

When selecting the right table saw blade for your woodworking needs, the type of cut required must be taken into consideration. There are two different types of blade used for woodworking- rip blades, which are intended for making long cuts along the grain of the wood, and crosscut blades, which are used to make short crosswise cuts. Rip blades have larger teeth that are set further apart to cut coarser than a crosscut blade. Crosscut blades typically have more teeth that are spaced closer together to make clean cut edges.

Depending on the task being undertaken and whether a fast or smooth finish is required, you should select either a combination or full kerf (thickness) blade. A combination blade will make both rip and cross cuts, but may not be as precise as a full kerf blade. Full kerf blades require more power to spin them due to their thickness so they tend to result in cleaner cuts. They can also handle tougher materials such as dense hardwood with greater ease than thinner blades do.

With either type of blade you will want to select one with carbide-tipped teeth for longer life and better performance on harder materials such as hardwoods, plywood and particle board. Stainless steel or aluminum blades should not be chosen as they may cause rusting over time and will not hold an edge as well when cutting through tough materials such as hardwoods or particle board.

Material being cut

The material you are cutting will have a major impact on which blade to use. When selecting a blade, you need to consider what type of wood or other materials you plan on cutting. Different types of materials require different types of blades, and each has its own unique set of characteristics that can affect the quality and speed of your cuts.

Softwoods: Softwoods are found in many applications, such as crafting and construction projects. Common softwoods include pine, spruce, redwood, cedar and fir among many others. Generally speaking, any saw blades with 10 or more teeth per inch (TPI) will work best when cutting most softwoods.

Hardwoods: Hardwood comes in a variety of common species, including maple, oak, walnut and mahogany among others. Hardwoods are generally denser than softwoods but can still be cut with typical saw blades if your goal is precision cuts; however harder woods like plywood, may benefit from using blades designed specifically for such materials because they contain more teeth per inch (TPI) than standard saw blade options.

Non-Wooden Materials: Other non-wooden materials that require special tools when being cut include plastic laminate flooring and ceramic tile. Specialized saw blades for these types of materials generally feature fewer TPI but thicker kerf-size so the material is accurately cut without producing chips or splinters along the edges that could weaken the integrity of your finished project.

Blade diameter and arbor size

The blade diameter is measured in inches and is usually either 10, 12 or 14-inches. It should match the size of the motor arbor, usually 5/8-inch, but can be a smaller size like 3/4-inch or 1-inch to fit a wide range of motors. The blade should also be made to fit the actual arbor size of your particular saw so it will sit securely and provide maximum power transfer. Most saws have an arbor size that is equal to the blade diameter; however, some have an overhung arbor which adds length and allows for multiple blades between different arbors on the same saw. Arbor sizes are described using fractional inches (such as 5/8”) or diameters (such as 22mm). Most table saw blades come with their own arbors that allow you to change out blades without removing them from the machine.

The number of teeth in a blade affects both the type and cut quality on various materials. More teeth generate finer cuts but require more power due to friction and heat buildup, so a narrow blade with fewer teeth may be better for hard woods which require less accurate cuts at higher feed rates than denser woods like plywood which need more cutting edges. For softer woods like pine, forty eight teeth is considered optimal; for harder woods like hardwoods thirty two is fine.

Tooth count and blade configuration

The number of teeth on the blade, or tooth count, will provide one of your most critical decisions when selecting a saw blade. More teeth mean a smoother cut and less tear-out from the material being cut. However, the more teeth that are present on the blade, the slower and harder it is for the blade to make its way through a tough material like hardwoods.

Blade configuration is also important for proper performance. There are two different types of blade construction: alternating top bevel (ATB) and flat top grind (FTG). ATB saw blades possess curvilinear edges while FTG saw blades possess sharpened edges with a flat top profile. ATB tooth blades produce a cleaner cut than FTG blades; however, FTG blades render smoother cuts in exotic materials where small pieces or chipping may occur from ATB blades. The number of teeth configured in either type of construction helps determine cut quality so be sure to read up on which design works best for your style of woodworking before making your purchase.

Blade quality and durability

When it comes to table saw blades, one of the most important considerations is quality and durability. Poor quality blades may be difficult to install, function poorly, and even cause safety issues. They may bend or chip easily and can often be unreliable when cutting wood, resulting in a poor finish or uneven edges. The best blades are made of high-quality steel that is hardened for strength and heat treated for maximum durability. Different types of steels offer different levels of performance, with some being better suited to tougher tasks while others are designed specifically for precision work.

In addition to blade quality and durability, other factors such as size, tooth configuration and cutting angle should also be taken into account when selecting a suitable table saw blade for your requirements. Blade size will largely depend on the type of materials you intend to cut; larger blades tend to be better suited for thicker materials while smaller ones are usually more suitable for thin pieces of wood or plastic. Tooth configuration determines the overall cutting action of the blade; finer teeth are great at producing smooth finishes while coarser teeth have more aggressive cutting capabilities but leave a rougher surface finish. Finally, cutting angle can also have an impact on the performance; lower angles result in a cleaner cut but require more effort from the motor while higher angles produce faster cuts but give rougher surface finishes.

Conclusion

When you select the right table saw blade for your woodworking project, you are investing in a quality tool that will enable you to make precise cuts with ease. However, it is important to remember that having the right blade for your specific need is as important as having the right table saw. Even if you have invested in a high-end saw, without the correct blade, it will not perform optimally.

By considering the type of materials you plan to cut and making sure your dimensions and blades match accordingly, you can improve cutting accuracy and save time on projects. Additionally, by knowing what to look for when purchasing a blade and investing in one that is of good overall quality, you can save yourself from potential frustration while working with wood in the future. Finally, by understanding how to care for and store your blades properly, you can extend their life so they last longer than expected.

Following these tips and practices will ensure that when choosing a table saw blade for your woodworking needs that it is one of the best investments for any DIYer or professional.

FAQ’s

What saw blade should I use for woodworking?

The type of saw blade you should use for woodworking depends on the type of cut you want to make, the type of wood you are working with, and the type of saw you are using.

How do I choose a table saw blade?

To choose a table saw blade, consider the type of cut you want to make, the material you are cutting, the number of teeth on the blade, and the blade diameter.

How much higher should a table saw blade be than the wood?

A table saw blade should be raised about 1/8 inch higher than the thickness of the wood being cut.

What are 3 common types of table saw blades?

Three common types of table saw blades are rip blades, crosscut blades, and combination blades.

What blades are best for cutting hard wood?

The best blades for cutting hard wood are carbide-tipped blades with a high tooth count.

What are the 5 most common types of saws used in woodworking?

The 5 most common types of saws used in woodworking are table saws, circular saws, jigsaws, miter saws, and hand saws.

What is the most common saw for woodworking?

The most common saw for woodworking is the table saw.

What are the 4 types of saw blades?

The four types of saw blades are rip blades, crosscut blades, combination blades, and dado blades.

Is more teeth better on a saw blade?

More teeth on a saw blade can result in a smoother cut, but it may also increase the amount of heat generated during cutting and reduce the speed of cutting.

What is the best table saw blade for pressure treated wood?

A carbide-tipped rip blade with a low tooth count is the best table saw blade for cutting pressure treated wood.

See Also:

- Best 12 inch miter saw blade

- Best 10 inch table saw blade

- Best 8 1/4 table saw blade

- Best 7 inch wet tile saw blade

- Best 7 1/4 circular saw blade