Do you find it difficult to choose the best blade for your radial arm saw? Are you looking for something that can cut through various materials seamlessly with precision? Then look no further as this is your one-stop guide providing expert knowledge of the best blades available in 2023. Get ready to take your projects to the next level!

Best blade for radial arm saw 2023

- Norske Tools NCSBP257 Aluminum Saw Blade (Editor’s Pick)

- Freud LU82M009 Blade (Best Overall)

- NEIKO 10768A Carbide Chop Saw Blade (Budget Friendly)

- Amana Tool – RA1440 Carbide Saw Blade

- Freud LU91R010 Miter Saw Blade

- WEN 32 Tooth 10 inch Saw Blade

- CRAFTSMAN CMAS210CMB Miter Saw Blade

1) Norske Tools NCSBP257 Aluminum Saw Blade

Mitre and compound design distinguish the Norske Tools NCSBP257 Aluminium Saw Blade. These unique features unlock accurate cuts, making cutting easy. Avoid the kickback of inferior blades with this tool; safety comes first.

Stability Every Stroke

Imagine making a key cut and needing stability. The radial blade design saves you. It increases stability and lowers blade stress. Each stroke with the Norske Tools NCSBP257 Aluminium Saw Blade is reliable.

Professionals’ Best Friend

Professionals looking for a reliable cutting buddy should use this blade. Its top-notch materials provide unrivalled durability and longevity. An investment, not just a tool. The Norske Tools NCSBP257 Aluminium Saw Blade is a durable instrument.

Unleash Versatility

Cutting aluminium, brass, plastic, or copper? No problem! The Norske Tools NCSBP257 Aluminium Saw Blade is multifunctional. Norske’s sleek black shape and 100 teeth make it powerful. Its exquisite cuts and smooth finishing set it apart from the competitors.

All-in-One Solution

Its material versatility makes this blade stand out. End the headache of switching blades for different jobs. Norske Tools NCSBP257 Aluminium Saw Blade is an all-in-one solution. This blade changes the game by saving time and eliminating errors.

Lightweight Durability

This blade’s high-quality aluminium, brass, and plastic materials blend lightweight manoeuvrability and durability. Using it won’t tyre you out at 1.78 pounds. Working for long periods without hand fatigue is easy with this blade.

Ultimate Choice

Overall, the Norske Tools NCSBP257 Aluminium Saw Blade is reliable and versatile. Modern design, material compatibility, and precision make it the best choice for pros and DIYers. This blade delivers precise cuts with reliability.

The Norske Tools NCSBP257 Aluminium Saw Blade will improve your cutting and workmanship.

Must Read – Best dado blade for table saw

Norske Tools NCSBP257 Aluminum Saw Blade First Hand Review Video

Video Source: Shahtive

Pros:

- The Norske Tools NCSBP257 Aluminum Saw Blade is compatible with multiple materials, reducing the need to switch blades frequently.

- With 100 teeth, this saw blade provides precise cuts and smooth finishes.

- Made of high-quality aluminum, brass, and plastic materials, this blade is durable and lightweight.

- The modern design and sleek black color of the blade add a touch of style to any tool collection.

- The package dimensions of 12.24 x 10.91 x 0.28 inches make it easy to store and transport.

CORE FEATURE

| Material | Aluminum,Brass,Plastics |

| Brand | Norske |

| Color | Black |

| Number of Teeth | 100 |

| Style | Modern |

| Compatible Material | Aluminum, Brass, Plastic, Copper |

| Part Number | NCSBP257 |

| Item Weight | 1.78 pounds |

| Package Dimensions | 12.24 x 10.91 x 0.28 inches |

2) Freud LU82M009 Blade

The Freud LU82M009 Blade truly cuts above. A radial design reduces vibrations during operation, assuring accuracy and stability. This means you can confidently make delicate cuts knowing the blade won’t fail.

Keeping Cool Under Pressure

Tools can wear out, but not the LU82M009 Blade. Overheating and warping are greatly reduced by its intelligent expansion slots. This protects your blade and guarantees consistent performance over long cutting sessions.

Durability meets precision

Professionals like the Freud LU82M009 Blade for high-quality saw blades. It’s made of durable carbide to withstand continuous use without sacrificing performance. This blade, model number LU82M009, is lightweight and simple to handle at 1 pound, making it your go-to tool for effortlessly slicing through tough materials.

Top-notch professional quality

The Freud LU82M009 Blade is known for handling difficult tasks. Professional contractors require it to have a 1-volt voltage and 1-watt wattage for unmatched cutting power. Professionals need look no further for a reliable and effective tool.

Best Versatility

Freud LU82M009 Blade is a handy tool for many uses. Its multi-color design and one-size-fits-all compatibility make it easy to use with different saws. The blade’s metric measurement system ensures exact cuts in any material.

Conclusion: The Best Cutting Partner

The Freud LU82M009 Blade epitomises saw blade durability and precision. Contractors and DIYers choose it for its professional quality, adaptable design, and unrivalled cutting power. Freud’s LU82M009 Blade delivers precision and durability every time. Improve your cutting game today!

Must Read – Best jig saw blade for plywood

Freud LU82M009 Blade First Hand Review Video

Video Source: Casual DIY

Pros:

- The Freud LU82M009 Blade is made of durable carbide material, ensuring long-lasting performance.

- With a weight of only 1 pound, this blade is lightweight and easy to maneuver.

- The blade’s professional-grade quality makes it an ideal tool for contractors who need a reliable and efficient saw blade.

- The multi-color design and one-size-fits-all make it easy to use with different types of saws.

- The metric measurement system ensures precise cuts every time.

CORE FEATURE

| Part Number | LU82M009 |

| Item Weight | 1 pounds |

| Product Dimensions | 1 x 1 x 1 inches |

| Size | One Size |

| Color | Multi |

| Material | Carbide |

| Voltage | 1 Volts |

| Wattage | 1 watts |

3) NEIKO 10768A Carbide Chop Saw Blade

Durability and precision define the NEIKO 10768A Carbide Chop Saw Blade. Its high-quality carbide substance resists wear and tear, keeping it sharp and reliable even after extensive usage. This blade takes on the toughest materials with ease, changing the game for cabinet makers and woodworkers.

Interchangeable Variety

The NEIKO 10768A Carbide Chop Saw Blade is versatile. Its ingenious design makes blade interchangeability straightforward, allowing you to adapt to different cutting applications. This blade works on wood, steel, aluminium, and plastic.

The Neiko Legacy

This saw blade from Neiko, a tool industry pioneer, shows their dedication to quality. Neiko’s reputation for high-quality tools assures that the NEIKO 10768A Carbide Chop Saw Blade meets the highest requirements. The sleek silver finish and sophisticated design bring flair to any workshop.

Precision in Every Tooth

This blade’s 80 teeth for precise cuts and flawless finishes. This capability makes even the hardest tasks easy when working with steel and aluminium. This blade balances manoeuvrability with stability at 11.97 x 11.97 x 0.38 inches and 2.54 pounds, making accurate cuts easy.

A Multipurpose Cutting Partner

For many cutting tasks, the NEIKO 10768A Carbide Chop Saw Blade is reliable. This blade effortlessly slices pipes and metal sheets and cuts wood and plastic precisely. Its sleek design and silver finish make it popular among DIYers and pros.

Made to Last

The quality and performance of this blade are enhanced by its Chinese manufacturing. It’s built to withstand tough cutting operations, making it a workshop staple for years.

Conclusion

The NEIKO 10768A Carbide Chop Saw Blade is trustworthy, resilient, and adaptable enough for even the toughest cutting jobs. Modern design, 80 teeth, and wide range of applications make it a favourite among woodworking pros and DIYers. This amazing saw blade makes woodworking projects precise and easy.

Must Read – Best metal cutting circular saw blade

NEIKO 10768A Carbide Chop Saw Blade First Hand Review Video

Video Source: The Tools World

Pros:

- The NEIKO 10768A Carbide Chop Saw Blade has 80 teeth, making it ideal for precision cuts and smooth finishes.

- With a weight of 2.54 pounds, this blade is easy to handle and maneuver.

- Made of durable carbide material, this saw blade ensures long-lasting performance even with frequent use.

- The blade’s modern design and silver color make it a stylish addition to any tool collection.

- The blade is versatile and can be used for various cutting applications, from metal sheets to plastic.

CORE FEATURE

| Is Discontinued By Manufacturer : | No |

| Product Dimensions : | 11.97 x 11.97 x 0.38 inches; 2.54 Pounds |

| Country of Origin : | China |

| Material | Carbide |

| Brand | Neiko |

| Item Dimensions LxWxH | 11.97 x 11.97 x 0.38 inches |

| Color | Silver |

| Number of Teeth | 80 |

4) Amana Tool – RA1440 Carbide Saw Blade

The 14-inch Amana Tool – RA1440 Carbide Saw Blade is adaptable for cutting applications. This blade’s 40 teeth are highly honed for precision cuts and smooth finishes on hardwood, softwood, and non-ferrous metals.

Optimized Hook Angle and Tooth Grind

This saw blade’s carbide teeth are skillfully honed at a 10-degree angle to improve cutting performance. The blade also has a -2 degree hook angle for smoother, more controlled cuts. These design features make it ideal for handling a variety of materials.

Safe and Confident

The Amana Tool – RA1440 Carbide Saw Blade fits most saws with a 1-inch bore. This fits securely, reducing use-related injuries. The blade’s logo reinforces quality, providing you peace of mind that you’re using a solid tool.

Built to Last

This saw blade is durable, and the Amana Tool – RA1440 Carbide Saw Blade is no exception. Made of high-quality carbide, it can resist frequent use without sacrificing performance. Its 4.2-pound weight makes it a sturdy cutting tool.

Versatility for Projects

The Amana Tool – RA1440 Carbide Saw Blade is versatile for professionals and DIYers. Its 14-inch diameter, 40 teeth, 1-inch bore, 10 degrees tooth grind, and -2 degrees hook angle make it suited for many cuts. From precise work to common applications, this blade can help.

Conclusion

The Amana Tool – RA1440 Carbide Saw Blade is a top-notch cutting tool with precision, durability, and versatility. Its strong structure and ability to make fine cuts and smooth finishes on diverse materials make it a reliable choice for pros and DIYers. For cutting projects that surpass the competition, try the Amana Tool – RA1440 Carbide Saw Blade.

Must Read – Best miter saw blade

Amana Tool – RA1440 Carbide Saw Blade First Hand Review Video

Video Source: ToolsToday

Pros:

- The Amana Tool – RA1440 Carbide Saw Blade is made of durable carbide material, ensuring long-lasting performance.

- With 40 teeth, this saw blade provides precision cuts and smooth finishes.

- The blade’s 1-inch bore ensures a tight and secure fit on most saws, reducing the risk of accidents while in use.

- The blade’s specifications make it ideal for different types of cuts, ensuring that users can work on different materials with ease.

- The package dimension and weight of the blade make it easy to store and transport.

CORE FEATURE

| specifications | (D) diameter: 14 (350mm) |

| specifications | Teeth: 40 |

| specifications | (D) Bore: 1 |

| specifications | Tooth grind: 4&1 |

| specifications | Hook angle: -2° |

| Package Dimensions : | 17.2 x 17 x 0.5 inches; 0.09 Ounces |

5) Freud LU91R010 Miter Saw Blade

The Freud LU91R010 Mitre Saw Blade is unique. Precision engineering makes it a marvel that cuts perfectly every time. Find out what makes it unique.

Perfect Fit for Stability

With a 5/8-inch arbor, this blade fits snugly on your saw. This solidity is needed for professionals’ precise cutting. Eliminate errors and wobbles.

Always Clean Cuts

The blade grind is carefully developed to ensure clean cuts every time. The Freud LU91R010 gives hardwood, softwood, and non-ferrous metals smooth, professional finishes.

Stability meets durability

It’s not just for show—this blade’s hefty plate improves longevity and stability. With this powerful weapon, you won’t wear out quickly.

Vibration-free operation

Nobody destroys precision like vibrations and noise. High tooth density of 40 teeth solves this problem for the Freud LU91R010 Mitre Saw Blade. This feature reduces vibrations and noise, allowing you complete control over your cuts.

Taming Drift

The last thing you want is the blade to wander during a key cut. The Freud LU91R010 Mitre Saw Blade has a 10-degree hook angle. This design aspect keeps the blade on track, ensuring perfect cuts.

Fighting the Elements

No one loves rusted blades. The Freud LU91R010’s anti-corrosion coating protects the blade against rust and other damage. It’s built to endure harsh environments.

A Professional Tool

The Freud LU91R010 Mitre Saw Blade is suitable for professionals that want high-performance instruments. The blend of materials and 60 teeth produce accurate cuts, making it a reliable companion for many cutting applications.

Light and User-Friendly

Despite its excellent performance, the Freud LU91R010 weighs only 0.15 pounds. The 6.25 x 0.82 x 0.51-inch item is easy to handle, decreasing hand fatigue during lengthy use. This blade prioritises comfort and efficiency.

Precision in Every Cut

The Freud LU91R010’s metric measurement system ensures accurate cuts. This blade eliminates guessing and trial-and-error with each pass. Its multi-color design also beautifies your tool collection.

Fits All

Freud LU91R010 Mitre Saw Blades are versatile. Its one-size-fits-all design, 1-volt voltage, and 1-watt power make it suitable with many saws. This blade adapts to wood and metal, allowing for precise cuts.

Conclusion

Overall, the Freud LU91R010 Mitre Saw Blade is durable, precise, and versatile. Its durable design, vibration-taming ability, and corrosion resistance make it a popular choice for experts and DIYers. Improve your cutting pleasure with the Freud LU91R010 and enjoy beautiful cuts every time.

Must Read – Best miter saw blade for fine cuts

Freud LU91R010 Miter Saw Blade First Hand Review Video

Video Source: Sawblade.com

Pros:

- The Freud LU91R010 Miter Saw Blade is made of a blend of materials, ensuring long-lasting performance even with frequent use.

- With 60 teeth, this saw blade provides precision cuts and smooth finishes.

- The blade’s metric measurement system ensures precise cuts every time.

- The blade’s one-size-fits-all design and 1-volt voltage and 1-watt wattage make it an ideal tool for different types of saws.

- The blade’s lightweight design reduces the risk of hand fatigue during prolonged use.

CORE FEATURE

| Material | Blend |

| Brand | Freud |

| Item Dimensions LxWxH | 6.25 x 0.82 x 0.51 inches |

| Color | Multi |

| Number of Teeth | 60 |

| Item Weight | 0.15 Pounds |

| Part Number | LU91R010 |

| Item Weight | 2.4 ounces |

| Product Dimensions | 6.25 x 0.82 x 0.51 inches |

6) WEN 32 Tooth 10 inch Saw Blade

The WEN Saw Blade is made of high-quality materials to last and perform well. It promises smooth woodcutting, simplifying woodworking projects. For flawless results, the WEN 32 Tooth 10 inch Saw Blade is a smart investment for professionals and hobbyists.

Precision and Durability Win

Precision distinguishes the WEN 32 Tooth 10 inch Saw Blade. It cuts accurately and smoothly with 32 teeth, making it excellent for wood slicing. Its trendy design and sleek black colour bring beauty to your tool collection while excelling in usefulness. This blade’s wood compatibility makes it a favourite among DIY woodworkers.

Unleash Versatility

The WEN 32 Tooth 10 inch Saw Blade is multipurpose. Its durable carbide structure makes it a favourite tool for professionals working on a variety of jobs. Its 13.5 x 11 x 0.5-inch box size and one-item quantity make it easy to store and transport. You can take it wherever your woodworking journey takes you.

In conclusion

The WEN 32 Tooth 10 inch Saw Blade is a durable, high-quality cutting instrument. Professionals and DIYers love its precision cuts, versatility, and exquisite appearance. Try the WEN 32 Tooth 10 inch Saw Blade and see the difference in your woodworking results. This durable tool will elevate your woodcutting efforts.

Must Read – Best miter saw blade for trim

WEN 32 Tooth 10 inch Saw Blade First Hand Review Video

Video Source: WEN Products

Pros:

- The WEN 32 Tooth 10 inch Saw Blade is made of durable carbide material, ensuring long-lasting performance.

- With 32 teeth, this saw blade provides accurate and smooth cuts.

- The blade’s modern design and black color make it a stylish addition to any tool collection.

- The blade is compatible with wood, making it a popular choice among DIY enthusiasts.

- The blade’s package dimensions and one-item package quantity make it easy to store and transport.

CORE FEATURE

| Material | Carbide |

| Brand | WEN |

| Color | Black |

| Number of Teeth | 60 |

| Style | Modern |

| Compatible Material | Wood |

| Part Number | BL1032-2 |

| Item Weight | 2.99 pounds |

| Package Dimensions | 13.5 x 11 x 0.5 inches |

| Item Package Quantity | 1 |

7) CRAFTSMAN CMAS210CMB Miter Saw Blade

The CRAFTSMAN CMAS210CMB Mitre Saw Blade is precision-built to cut perfectly every time. Those who expect perfection need it more than a tool. The CRAFTSMAN CMAS210CMB Mitre Saw Blade is your best friend for home renovations and furniture making, providing unmatched quality and precision. With this blade’s toughness and accuracy, only success is possible.

Built to Last

The CRAFTSMAN CMAS210CMB Mitre Saw Blade is the most reliable for wood and other materials. Made of high-quality carbide, it cuts precisely and leaves a flawless finish that shows off its expertise. With a part number of CMAS210CMB and a weight of 3.32 pounds, this blade becomes an extension of your hand, making delicate manoeuvres easy.

Versatility Redefined

The versatile CRAFTSMAN CMAS210CMB Mitre Saw Blade is outstanding. With a 10-inch blade and 24 teeth, it easily cuts a variety of materials. Add style to your toolset with its sophisticated design and eye-catching red and silver colour scheme. It works smoothly with corded electric power sources and a variety of saws, increasing its use throughout your projects.

The Reliable Friend

For all your cutting needs, the CRAFTSMAN CMAS210CMB Mitre Saw Blade is a reliable partner. Its high-quality carbide substance ensures long-lasting performance for professionals managing complex projects. With 13.89 x 10.71 x 0.28 inches and a single-item packaging quantity, storing and carrying this blade is easy, so you can always have it with you.

The Decision

In conclusion, the CRAFTSMAN CMAS210CMB Mitre Saw Blade is an example of quality. Professionals and DIYers appreciate it for its precision, versatility, and attractive design. The CRAFTSMAN CMAS210CMB Mitre Saw Blade unlocks the pinnacle of craftsmanship by seamlessly combining aesthetic and utility.

Must Read – Best pole saw blade

CRAFTSMAN CMAS210CMB Miter Saw Blade First Hand Review Video

c

Video Source: Handy Ginger

Pros:

- The CRAFTSMAN CMAS210CMB Miter Saw Blade is made of high-quality carbide material, ensuring long-lasting performance.

- With 24 teeth and a blade length of 10 inches, this saw blade provides precision cuts and smooth finishes.

- The blade’s modern design and red and silver color make it a stylish addition to any tool collection.

- The blade is compatible with corded electric power sources, making it an ideal tool for different types of saws.

- The blade’s package dimensions and one-item package quantity make it easy to store and transport.

CORE FEATURE

| Material | Carbide |

| Brand | Craftsman |

| Color | Red, Silver |

| Number of Teeth | 24 |

| Style | Modern |

| Part Number | CMAS210CMB |

| Item Weight | 3.32 pounds |

| Package Dimensions | 13.89 x 10.71 x 0.28 inches |

| Size | 10-in. |

Best blade for radial arm saw 2023-Complete buying Guide

Choosing the right radial arm saw blade for your saw and material can be a tricky process. What may have been ideal for cutting logs with your old-fashioned handsaw last year may not be the best choice today. With advancements in materials, teeth technology and coating, there is a large selection of blades available. To ensure you are getting the most out of your investments, it is important to understand the different types of blades and their uses before heading to the store for replacement blades.

In this guide, we will discuss how blade geometry affects cutting performance and provide an overview of different types of radial arm saw blades available today. We will also discuss considerations when purchasing new blades so that you can feel confident that you are making an informed purchase decision.

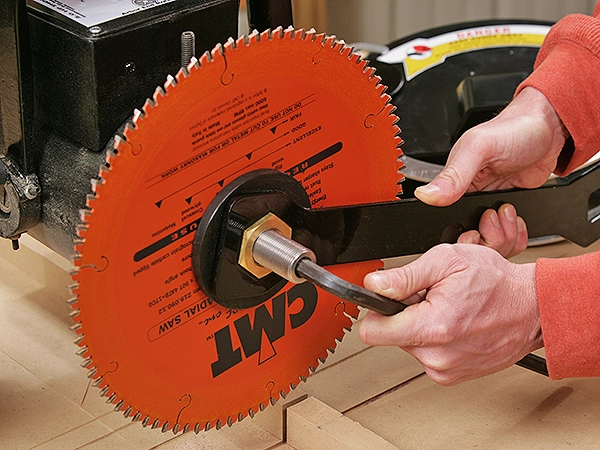

Photo Source: woodworkersjournal.com

Definition of a radial arm saw

A radial arm saw is a power tool featuring a circular saw mounted on an arched arm which is mounted across the table. These tools are used to crosscut, rip, and miter material for construction or woodworking projects.

Radial arm saws have three basic parts:

- The base, which holds the motor and operates like a drill press with its up/down motions.

- The arm, which is usually attached to an articulated column that extends out from one side of the table and can be adjusted in length while connected to its post.

- The head on top of the arched metal arms hold both the motor and blade in place while they spin.

Importance of having the right blade

Having a correctly sized and correctly chosen blade for your radial arm saw is essential in order to get the best possible results when cutting. The right blade can help to make sure that your cuts are smoother, more precise and faster than with a blade that is not suited to the task at hand. But it is important not just to select the right size, but also to select a blade type that is best suited for your particular project – whether it be cutting through hardwoods or softer woods, or through plastics and metal.

A few factors to consider when choosing the right blade include:

- Cutter type – There are different types of cutters available, such as standard TCT blades, carbide tipped and diamond abrasive blades, designed for different types of materials. These should be selected depending on the material you will be cutting through.

- Tooth count and pitch – The size of the tooth determines how aggressive the cut will be – greater tooth count and lower pitch will provide a cleaner cut while fewer teeth and higher pitch allows for faster cutting speed but also rougher edges.

- Blade width – This should match up with the maximum depth of cut specified by your saw manufacturer; if you go too wide then you can risk damage to both your saw and workpiece.

By selecting an appropriate blade for your radial arm saw you will be able obtain the best results from each cut without damaging either your machine or workpiece.

Purpose of the guide

This buying guide has been created to help readers understand the features and unique capabilities of different blade types available for radial arm saws. It will provide readers with information on the best blade types for specific functions, such as ripping, cutting, and crosscutting.

This guide will also discuss key factors to consider when selecting a radial arm saw blades and recommend specific blades based on a user’s needs. Additionally, this buying guide will provide information about features like tooth pattern and kerf design to help buyers make an informed purchase decision.

Ultimately, the goal of this buying guide is to assist readers in selecting the right blade so they can get the most out of their radial arm saw.

Types of blades

Radial arm saw blades come in a wide variety of diameters, tooth-counts, kerf widths, materials and configurations. It may be hard to decide which radial arm saw blades are best for your project. To help make the decision easier, here is an overview of the various types of radial arm saw blades available and their uses:

- Combination Blades: These blades are designed for general purpose cutting on both hardwoods as well as softwoods. They usually have larger teeth with narrower gullets that produce a smoother cut. A good combination blade can easily excel in both rip and crosscut applications.

- Ripping Blades: A ripping blade is generally designed to handle the cutting of hardwoods or plywood along the grain (rip cuts). The blade typically has more teeth with fewer gullets than other blades, which produce less tear out in material while cutting along the grain.

- Crosscut Blades: Crosscut blades are specialized to cut across material fibers (crosscuts). They typically have more teeth with larger gullet sizes that allow for better chip clearance when doing crosscuts on hardwoods or softwoods like pine or cedar.

- Dado Blades: Dado blades are primarily used for shallow dadoes (grooves) and rabbets that join two materials together such as furniture or cabinet construction and making box joints, among other uses. Generally these come in 6 inch diameters with 8 inch sets containing multiple chipper blades between outer main cutters to create a dado of variable widths.

- Flat Ground ATB/TCG Blades: Often referred to as specialty cuts these types of blades have flat tooth bevels that produce a finer finish when crosscutting softwood materials like pine, poplar and maple.

Crosscut blades

Crosscut blades, or miter saw blades, are the most common type of blade used on a radial arm saw. These blades have high tooth counts and a large gullet between each of the teeth to allow clearance for tearing out wood fibers as the blade cuts. Additionally, crosscut blades are designed with specific angles to efficiently cut across and across-grain material.

The most popular crosscut blade for radial arm saws is usually a combination or general purpose type material, which is designed for both ripping and crosscutting different materials evenly. Quality materials such as plywood, particleboard, hardwood, and softwood can be efficiently cut with the help of crosscut blade. The small kerf of some types makes them ideal for smaller shop projects where saving material is important.

To get best results while use Cross cut blades choose one that has a suitable positive hook angle in accordance with your material being ripped or crosscut. To ensure you’re using the right type of blade, always double-check the manufacturer’s specifications before use as different materials require different types of blades.

Rip blades

Rip blades, sometimes referred to as framing blades, are designed primarily for cutting along the grain of the wood. They typically have deep gullets to remove large shavings as quickly and efficiently as possible, as well as large numbers of (typically 24 or more) robust teeth that are specifically ground for a ripping application. As a result rip blades can be used on most woods and soft composite materials with good results but should generally not be used for cross slicing, especially on thin stock.

Additionally, in the case of harder exotic woods, narrow kerf designs – blades with thinner setup – can produce better results when ripping due to the higher tooth density producing smoother finishes and less susceptibility to chipping.

When selecting a rip blade you should focus not only on the number of teeth but also on their shape and size – often referred to as tooth geometry – which can vary across different models even with identical tooth counts. These features play an important role in determining how well your saw blade performs under various conditions; small-teeth thin kerf designs perform best in hardwoods while larger-tooth diameters with thick kerfs perform better in softwood applications. Finally you’ll want to consider the materials used – carbide tips tend to last longer than more common steel tip varieties – which can often make a significant difference when cutting harder wood species such as Oak or Walnut.

Combination blades

Combination blades are highly popular among avid DIYers and professional woodworkers for their multi-functionality. A combination blade is a great choice for everyday sawing needs due to its unique design that combines aspects of both a crosscut and rip blade.

Combination blades vary in tooth count and hook angles, featuring anywhere from 10 to 80 total teeth, with varying hook angles depending on the sawing application the blade will be used for. The hook angle determines how easily the material being cut can be pushed with the teeth: For example, a combination blade with an increased hook angle will cut material more easily than one with a lower hook angle.

Additionally, combination blades often have more alternate tooth set pattern designs as well as thicker bodies than other types of blades; this makes them an ideal choice for working with thick woods and other tough materials, providing strong performance even in difficult cutting applications.

Specialty blades

Radiating arm saw owners can also choose specialty blades, which are more specific in their purpose. Options like dado blades when purchased together as a set, come with five separate blades to let you cut different widths of grooves. A combination blade, on the other hand, will tackle a variety of aggregate materials from paneling to trim work. Another specialty blade is an aluminum cutting one that is specifically made for cutting softer metals like aluminum and copper with little to no tear-out.

These specialized blades are only for those projects when you need precision cuts that cannot be done with a standard blade. For example, if you are cutting block wall insulation or small tile pieces then your project calls for a tile blade set while stress-rated stacking laminates need special slicing capabilities offered by a laminate flooring blade set. While not recommended as your everyday go-to tool, these specialty blades offer tangible performance boosts when the right fit is acquired and installed correctly.

Photo Source: dustylumberco.com

III. Factors to consider when choosing a blade

There are several factors to consider when selecting the best blade for your radial arm saw. The most important factor is your saw’s horsepower and RPM rating. Make sure the blade you choose is rated for a higher horsepower/RPM than what your saw is rated for. This rating is usually printed right on the packaging.

Another thing to consider when selecting the right blade is the type of material it was designed to cut. Some blades are better suited for hardwoods and others will work better with softer woods, such as pine or spruce. You must also make sure that the teeth of the blade are compatible with your materials; they must be designed appropriately so they don’t get dull quickly or cause burning and splintering on softer woods.

Finally, choosing an appropriate tooth configuration and number of teeth per inch is also important in achieving a smooth cut result from your radial arm saw. The more teeth you have, the finer and more consistent the finished product, though many professionals prefer fewer teeth for faster cuts through thicker materials. Be sure to check customer reviews before making any purchases since this can help determine whether a particular blade configuration will work well with your materials or not.

Material of the blade

When deciding on the best radial arm saw blade for your needs, the material of the blade should be considered first. There are two common types of materials used in radial saw blades: carbide-tipped and high-speed steel (HSS). Both are designed to provide a good balance between durability and cutting performance.

Carbide-tipped blades are more expensive than HSS blades, but they offer superior cutting performance. This type of blade is particularly well-suited to hardwoods and other tough applications. While they cost more up front, they can provide a longer lifespan, making them more cost-effective over time.

High speed steel blades offer excellent strength and durability at an economical price point. They may not perform quite as well as carbide tipped blades, but they’re great for general purpose use or if you’re looking for a blade that can handle a variety of materials with ease. They are also relatively easy to sharpen when compared to carbide blades, so sharpening is something that can be done quickly and easily when needed.

Number of teeth

The number of teeth on a blade is an important factor to consider when buying a blade for a radial arm saw. The number of teeth have an impact on the speed, the smoothness and quality of cut, and the life span of the blade. In general, blades with more teeth provide better overall cutting performance.

Blade tooth count is measured in TPI or “Teeth Per Inch“; blades range from 4 to over 100 TPI depending on the application. A larger number of teeth offers smoother cutting performance, but requires greater horsepower to operate.

Common TPI for blades used in radial arm saws include:

- 10-24 TPI for general purpose activities like ripping,

- 14-18 TPI for crosscutting (where square edges are desired),

- 14-30 TPI for ripcutting (where quick stock removal is desired),

- 32-48 TPI for finish cutting (where smooth edges are desired), and

- 60+ TPI for highly intricate cuts with fine detail.

The right selection will depend on the job at hand and should always be confirmed with the manufacturer’s specification sheets.

Kerf

The Kerf is the width of the slot cut by the blade through your material. When selecting a blade, it is important to match the thickness of the kerf to the size of your saw. This is important because if the kerf is too small, then it can cause damage and stress on your machine as it attempts to cut through materials. If, however, the kerf is too large, then you will be cutting out more material than necessary for most tasks.

There are two main types of blades that vary in their kerf sizes – standard and thick:

- Standard-kerf blades are entry-level options with a standard width of about 3/32” to 1/8” and are suitable for most projects. These will work well with plywood, veneer and other softer hardwood materials.

- However, if you need to rip thicker materials like wide stock hardwoods or sheet goods, then we recommend using a thick-kerf blade instead. The larger kerfs (1/4” or 5/16”) on these blades are designed to handle tougher cutting jobs without bogging down your saw as much as thinner ones would during heavier tasks.

Plate thickness

The plate thickness of the blade you choose for your radial arm saw is important. Blades are available in a range of sizes and thicknesses – from thin 3/32 of an inch to a full 1/4 inch. Thicker blades can cut through harder materials (like steel), whereas thinner blades should be used for cutting softer materials (like wood). Most home users prefer thinner blades because they offer more flexibility when making small cuts. Blades with slightly thicker plates may be better suited for professional shops and other applications where maximum cut depth and strength are required.

When purchasing a blade, it’s important to check its plate thickness to ensure that it’s suitable for your needs.

Conclusion

Whether you are a DIY enthusiast or a professional carpenter, having the right blade for your radial arm saw is important for ensuring precise and precise cutting. There are many blades on the market today that can meet your needs, but not all blades are created equal. The size, type, and number of teeth per inch are important factors to consider when shopping for a blade, as they will determine how smooth and precise your cut is.

By considering all these factors and familiarizing yourself with the different types of blades available, you can make an informed decision on which blade is best suited to your project needs. Make sure that you use appropriate safety gear when using your radial arm saw to protect yourself from potential accidents or injuries.

Finally, follow manufacturer’s directions in regards to installation, storage, proper maintenance techniques and inspecting blades for signs of wear before use. Doing this will help you ensure that you have the best possible tool for complete control over any project task!

FAQ’s

What type of blade should you use on a radial arm saw?

A crosscut blade is typically used on a radial arm saw.

What type of cut should you not do with the radial arm saw?

Radial arm saws should not be used for rip cuts.

What is the most common size blade used on a radial saw?

The most common size blade used on a radial arm saw is 8-1/4 inch.

How many teeth does a radial arm saw blade have?

The number of teeth on a radial arm saw blade can vary, but typically ranges from 24 to 100 teeth.

What is a 24 tooth saw blade good for?

A 24 tooth saw blade is good for rough cuts and fast removal of material.

What is a 60 tooth saw blade good for?

A 60 tooth saw blade is good for smooth cuts on softer materials, such as plywood.

What is a 100 tooth saw blade used for?

A 100 tooth saw blade is used for fine, precise cuts on soft materials.

What is a 80 tooth saw blade used for?

An 80 tooth saw blade is used for general purpose cutting on both soft and hard materials.

What is a 90 tooth saw blade used for?

A 90 tooth saw blade is used for cutting with a high degree of accuracy on a variety of materials.

What is a 120 tooth saw blade used for?

A 120 tooth saw blade is used for ultra-smooth cuts on soft materials, such as melamine or veneered plywood.

Michael Lilli is the author and CEO of sawbladetown.com and Informative Website. With over 10 years of experience in the saw blade industry, Michael has become a leading expert in the field. He is dedicated to helping professionals and hobbyists alike find the perfect saw blade for their projects. Through his informative website and writing, Michael shares his knowledge and expertise on everything from saw blade anatomy to advanced techniques and safety precautions. His passion for saw blades and commitment to helping others has made him a trusted resource in the industry.