Are you struggling to find the best table saw blade for ripping hardwood in 2023? You’re in luck! This comprehensive guide will help you identify the right table saw blade to meet your needs and make your next job a success. Stop struggling and start creating with confidence!

Best table saw blade for ripping hardwood 2023

- WEN BL1040 Table Saws Blade (Editor’s Pick)

- Freud LM75R010 Blade (Best Overall)

- CMT ORANGE TOOLS Blade (Budget Friendly)

- BOSCH DCB1024 Table Saw Blade

- Freud D1024X Saw Blade

- DEWALT Circular Saw Blade

- CMT ORANGE TOOLS BLADE

1) WEN BL1040 Table Saws Blade

Woodworking requires precision. The WEN BL1040 Table Saw Blade cuts softwoods easily with its 15.88 mm diameter. This blade’s 254mm rating and compatibility with table saws up to 6000 RPM allow you to tackle a variety of applications.

Craft Cuts with Precision

WEN BL1040 Table Saw Blade is your trusted partner for woodworking projects including furniture, cabinetry, and more. Precision cuts with this blade satisfy the highest craftsmanship requirements. Look no farther for a reliable and efficient table saw blade.

Craftsmanship at Its Best: WEN BL1040 Table Saw Blade for Woodworking Excellence

For reliable and efficient woodworking blades, the WEN BL1040 Table Saw Blade should be your first choice. It fits most ordinary table saws and uses high-quality carbide material for clean, precise cuts. It serves to hobbyists and professionals with 40 woodcutting teeth.

The WEN Brand: Trustworthy

This table saw blade from WEN, a trusted power tool brand, is trustworthy. The bright red colour helps it stand out in your workshop and provides aesthetic appeal. The standard blade design fits most table saws and is optimised for efficient cutting.

Easy to Handle, Lightweight

The WEN BL1040 Table Saw Blade is lightweight at 1.46 pounds, making it easy to use. Its 13.7 x 11.06 x 0.47-inch size makes storage and transport easy. Additionally, it’s certified frustration-free, ensuring easy table saw installation. No batteries are needed, simplifying the setup even more.

The WEN BL1040 Table Saw Blade is a great choice for both beginners and pros. Its precision, reliability, and use make it a woodworker’s essential tool. Invest in this blade to maximise your woodworking tasks.

Must Read – Best miter saw blade for trim

WEN BL1040 Table Saws Blade First Hand Review Video

Video Source: Happy Shop

Pros:

- The WEN BL1040 Table Saws Blade is made with high-quality carbide material that ensures clean and precise cuts every time.

- The blade is designed to fit most standard table saws and features 40 teeth that are optimized for cutting through wood.

- The blade’s bright red color makes it easy to identify among other blades in your workshop.

- The blade is lightweight, easy to maneuver, and comes in frustration-free packaging.

- The WEN BL1040 Table Saws Blade is an affordable option that provides excellent value for your money.

CORE FEATURE

| Material | Carbide |

| Brand | WEN |

| Color | Red |

| Number of Teeth | 40 |

| Style | Standard |

| Compatible Material | Wood |

| Part Number | BL1040 |

| Item Weight | 1.46 pounds |

| Package Dimensions | 13.7 x 11.06 x 0.47 inches |

| Pattern | Saw Blade |

2) Freud LM75R010 Blade

The Freud LM75R010 Blade has a 12-inch diameter and a unique grind and hook design. Explore its essential features and how they might improve your woodworking.

Precision-Engineered Grind

A careful grind powers the Freud LM75R010 Blade’s performance. This grind is designed for maximum precision and low vibrations. This blade makes smoother, more accurate cuts for woodworkers and DIYers alike.

Ideal Hook Angle

Saw blade hook angles are crucial for precise cuts with little vibration. The well calibrated hook angle of the Freud LM75R010 Blade makes it ideal. It improves cutting stability, resulting in cleaner edges and less fatigue even after lengthy use.

Softwood Versatility

With a 0.1-inch kerf, the Freud LM75R010 Blade is versatile for softwoods. This makes it a useful tool for woodworkers because it may be used for cutting in many ways.

Speedy Performance

The Freud LM75R010 Blade is fast. It smoothly slices through softwoods at 6000 RPM, meeting the needs of experts and DIYers. Avoid irritating slowdowns and enjoy precise cuts.

Quality Guaranteed by Freud

Freud, a power tool legend, created the LM75R010 Blade. Freud quality and innovation ensure this blade lives up to its reputation.

Compact & Handy

The Freud LM75R010 Blade is practical. At 1 x 1 x 1 inches, it’s tiny and won’t take up workshop storage space. This smart design gives you a reliable ripping blade without taking up space for other equipment.

Availability Matters

Continued availability is a major benefit of the Freud LM75R010 Blade. You won’t waste time searching online for this blade. Freud keeps this product in stock so you can get it whenever you need it.

Compatible and Lightweight

The Freud LM75R010 Blade is very light at 1 pound. Woodworking projects are easy to navigate. Its 1 x 1 x 1 inch size make it compatible with most table saws, adding to its usefulness.

Finally

The Freud LM75R010 Blade is a reliable and effective ripping blade for woodworkers of all levels. With precision-engineered features, high-quality craftsmanship, and a trusted name, this blade will boost your woodworking. Choose the Freud LM75R010 Blade for smoother, more precise woodworking cuts.

Must Read – Best pole saw blade

Freud LM75R010 Blade First Hand Review Video

Video Source: WoodWorkWeb

Pros:

- The Freud LM75R010 Blade is made with high-quality carbide material, ensuring that it is durable and long-lasting.

- The blade is optimized for ripping through wood, making it an excellent choice for both hobbyists and professionals.

- The blade’s compact design and multi-color finish make it an attractive and efficient option for those with limited storage space.

- The Freud LM75R010 Blade is not discontinued by the manufacturer, ensuring that you can easily find and purchase it.

- The blade is lightweight and easy to maneuver, making it a great option for those who need to make precise cuts.

CORE FEATURE

| Is Discontinued By Manufacturer : | No |

| Product Dimensions : | 1 x 1 x 1 inches; 1 Pounds |

| Material | Carbide |

| Brand | Freud |

| Item Dimensions LxWxH | 1 x 1 x 1 inches |

| Color | Multi |

| Number of Teeth | 30 |

| Style | Ripping Blade |

| Item Weight | 1 Pounds |

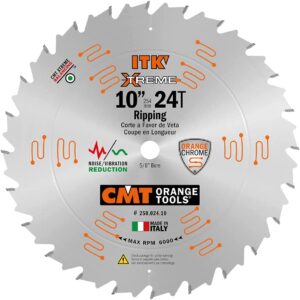

3) CMT ORANGE TOOLS Blade

The 10-inch CMT ORANGE TOOLS blade has a standard bore size and is compatible with many saws. Its adaptability makes it a desirable tool for woodworkers because it can adapt to different cutting needs.

Precision in Every Cut

The flat grind and rip construction of the CMT ORANGE TOOLS blade makes it ideal for cutting softwoods and other woods. This precision is necessary for every woodworker’s clean, accurate cuts. Stop having jagged edges and poor finishes.

Efficiency Meets Performance

The CMT ORANGE TOOLS blade is a masterpiece engineered to maximise performance and minimise vibration. This optimisation makes every cut accurate and smooth, improving your woodworking experience. Both experienced woodworkers and DIYers favour it for its reliability.

CMT Orange Tools Blade: Your Wood Ripping Partner

CMT ORANGE TOOLS Blades are reliable and efficient for woodworking jobs. This circular saw blade is made of high-quality carbide, ensuring durability and performance.

Tailored for Detail

This blade excels in chop miter and table saw applications with 24 wood-ripping teeth. Its sleek silver finish and compact size (6.25 x 0.82 x 0.51 inches) are designed for circular saw use, assuring precise cuts. The blade has a 10″ diameter, 5/8″ bore, and 0.126″ kerf to fulfil your woodworking needs.

Easy Wood Ripping

The CMT ORANGE TOOLS Blade excels at wood tearing. You can cut cleanly and precisely without hurting your workpiece with this blade. Its 15.8-ounce weight improves manoeuvrability and control.

Finally

The CMT ORANGE TOOLS Blade is a game-changer for woodworkers. This blade unlocks your woodworking potential with its high quality, precision, and efficiency. CMT ORANGE TOOLS Blade is your trusted partner for perfect mitre saw and table saw projects. Improve your woodworking skills and make every cut count with this amazing tool.

Must Read – Best pruning blade for reciprocating saw

CMT ORANGE TOOLS Blade First Hand Review Video

Video Source: 731 Woodworks

Pros:

- The CMT ORANGE TOOLS Blade is made with high-quality carbide material, ensuring that it is durable and long-lasting.

- The blade’s optimized design for chop miter and table saw use makes it an efficient option for woodworking projects.

- The blade is lightweight, making it easy to maneuver and control.

- The blade’s specific specifications, including its 10″ diameter and 5/8″ bore, make it a perfect option for those who need a specific set of features.

- The CMT ORANGE TOOLS Blade is an affordable option that provides excellent value for your money.

CORE FEATURE

| specifications | 10″ diameter, 5/8″ bore |

| specifications | Teeth: 24 FLAT Kerf: 0.126” |

| specifications | Machine Use: Chop Miter & Table Saw |

| specifications | Application: Ripping |

| specifications | Materials: Wood |

| Material | Carbide |

| Brand | CMT ORANGE TOOLS |

| Item Dimensions LxWxH | 6.25 x 0.82 x 0.51 inches |

| Color | SILVER |

| Number of Teeth | 24 |

| Style | Circular Saw |

4) BOSCH DCB1024 Table Saw Blade

Micrograin Carbide structure makes this blade durable and long-lasting. This cutting-edge material ensures the blade’s durability and ease of use with the toughest materials. The BOSCH DCB1024 Table Saw Blade is durable, so wear and tear won’t slow you down.

Easy Precision with Friction-Reducing Design

The BOSCH DCB1024 Table Saw Blade is durable, precise, and easy to use. Its friction-reducing design reduces build-up during cutting, making every cut smooth and effortless. Avoid irritating, time-consuming jams with quick, hassle-free woodworking.

C4 Carbide Construction for Durability

This blade’s C4 carbide construction will satisfy your high standards. It’s about continuously great performance, not simply longevity. This blade has the power and precision for large projects or intricate detailing.

Reasons to Use BOSCH DCB1024 Table Saw Blade

Woodworking requires dependability and efficiency. These attributes make the BOSCH DCB1024 Table Saw Blade the best choice for woodworkers of all levels. The reason:

1. BOSCH Quality Trust

This blade, made by power tool giant BOSCH, shows the brand’s dedication to excellence. BOSCH has a legacy of excellence.

2. Precision Matters

BOSCH DCB1024 Table Saw Blades are precise with 24 teeth. Every cut will be precise and clean, ensuring your woodworking projects turn out as planned.

3. Compatible with all

This 12 x 14 x 0.31-inch blade with a 5/8-inch arbor fits most table saws. You can use it with your current setup without any compatibility issues.

4. Quickness and Efficiency

Woodworking is time-consuming, and this blade knows it. Its fast cut grit description lets you finish jobs quickly without sacrificing quality. It’s lightweight at 1.2 pounds, making it easy to move.

Finally

The BOSCH DCB1024 Table Saw Blade will improve your woodworking skills. Top-quality materials, precision engineering, and a known brand name guarantee a durable and effective cutting tool. This blade eliminates frustrations and perfects carpentry. Try the BOSCH DCB1024 Table Saw Blade today and see how it improves your woodworking tasks.

Must Read – Best rip saw blade

BOSCH DCB1024 Table Saw Blade First Hand Review Video

Video Source: Bosch and Festool tools

Pros:

- The BOSCH DCB1024 Table Saw Blade is made with high-quality carbide material, ensuring that it is durable and long-lasting.

- The blade’s optimized design with 24 teeth and fast cut grit description ensures that you can make precise and efficient cuts quickly.

- The blade’s striking blue color makes it easy to identify among other blades in your workshop.

- The BOSCH DCB1024 Table Saw Blade is lightweight, making it easy to maneuver and control.

- The blade’s 5/8 In. arbor ensures compatibility with most table saws.

CORE FEATURE

| specifications | 5/8 In. arbor |

| Material | Carbide |

| Brand | BOSCH |

| Item Dimensions LxWxH | 12 x 14 x 0.31 inches |

| Color | Blue |

| Number of Teeth | 24 |

| Style | 24 Teeth |

| Item Weight | 1.2 Pounds |

| Part Number | DCB1024 |

| Product Dimensions | 12 x 14 x 0.31 inches |

5) Freud D1024X Saw Blade

Freud offers the 6.25 x zero.Eighty two x zero.51-inch multicolor D1024X Saw Blade. Most table saws work with present day layout, and 10" reducing diameter guarantees particular and efficient cuts.

Low-weight manoeuvrability

The Freud D1024X Saw Blade’s 2.Four-ounce weight is full-size. This lightweight blade makes clean, particular cuts for woodworkers. Its metric dimension machine additionally works nicely with workshop metric equipment.

Power of Carbide

Freud D1024X Saw Blade uses carbide. High-exceptional fabric makes the blade robust and short. Preventing warping and maintaining overall performance requires sturdiness.

Frictionless Cut

The titanium-coated blade aids woodworking. Cutting is easy considering the fact that friction and accumulation are decreased. Freud D1024X Saw Blades put off initiatives.

Contractors and Woodworker’s Flexibility

For sturdiness and performance, woodworkers and contractors admire this table saw blade. The Freud D1024X Saw Blade cuts for professionals and DIYers.

Finally

The Freud D1024X Saw Blade improves woodworking with its present day, reliable, and strong design. Its carbide creation, low vibration design, titanium coating, and light-weight maneuverability make smooth, particular cuts. Freud D1024X Saw Blade is right for woodworking.

Must Read – Best ripping blade for table saw

Freud D1024X Saw Blade First Hand Review Video

Video Source: Robert Dailey – Dailey Woodworks

Pros:

- The Freud D1024X Saw Blade is made with high-quality carbide material, ensuring that it is durable and long-lasting.

- The blade’s optimized design with 24 teeth ensures that you can make clean and precise cuts through wood.

- The blade’s modern style ensures compatibility with most table saws.

- The Freud D1024X Saw Blade is lightweight, making it easy to maneuver and control.

- The blade’s metric measurement system ensures compatibility with other metric tools in your workshop.

CORE FEATURE

| Material | Carbide |

| Brand | Freud |

| Item Dimensions LxWxH | 6.25 x 0.82 x 0.51 inches |

| Color | Multicolor |

| Number of Teeth | 24 |

| Style | Modern |

| Item Weight | 0.15 Pounds |

| Part Number | D1024X |

| Item Weight | 2.4 ounces |

| Product Dimensions | 6.25 x 0.82 x 0.51 inches |

6) DEWALT Circular Saw Blade

This extreme-duty circular saw blade resists collisions and wear like no other. Stabiliser vents enhance heat dissipation, minimising blade overheating and distortion. The DEWALT Circular Saw Blade is perfect for professionals and DIYers for precision cutting on any project.

DEWALT Circular Saw Blade: Easy Cuts You Can Trust

Looking for a great woodworking circular saw blade? Stop looking. This blade shows DEWALT’s quality with premium materials for durability. 24 teeth and a narrow kerf make this blade smooth for wood cutting.

DEWALT, a power tool company, is known for its excellence and innovation. DEWALT Circular Saw Blade 8.5 x 0.5 x 9.75 inches. Its universal design makes it easy to use with most table saws.

Precision Cutting at Its Best

The DEWALT Circular Saw Blade’s thin kerf sticks out. This function improves woodworking by making cutting smooth and efficient. This 8.8-ounce blade is lightweight and easy to use. You can use it for many jobs because it works with wood.

Finally

The DEWALT Circular Saw Blade is ideal for precision, durability, and ease of use. DEWALT’s exceptional performance may boost your woodworking outcomes. Make the smart choice today and see the difference. For the greatest woodworking results, use the DEWALT Circular Saw Blade.

Must Read – Best saw blade

DEWALT Circular Saw Blade First Hand Review Video

Video Source: Berlin Builds

Pros:

- The DEWALT Circular Saw Blade is made with a blend of materials, ensuring that it is durable and long-lasting.

- The blade’s optimized design with 24 teeth and thin kerf ensures smooth and efficient cuts through wood.

- The blade’s new style ensures compatibility with most table saws.

- The DEWALT Circular Saw Blade is lightweight, making it easy to maneuver and control.

- The blade’s compatibility with wood materials ensures that you can use it for a wide range of projects.

CORE FEATURE

| specifications | Thin kerf design for smooth cuts |

| Material | Blend |

| Brand | DEWALT |

| Item Dimensions LxWxH | 8.5 x 0.5 x 9.75 inches |

| Color | Multi |

| Number of Teeth | 24 |

| Style | New |

| Compatible Material | Wood |

| Part Number | DWA171424 |

7) CMT ORANGE TOOLS BLADE

The ultra-thin 0.071-inch plate thickness and revolutionary kerf design of the CMT ORANGE TOOLS BLADE set it apart. This unique feature makes cutting smooth and precise. Smoothly glide through hardwoods without harsh edges or uneven finishes.

Excellent Performance Micrograin Carbide Teeth

This outstanding blade has micrograin carbide teeth. These teeth are designed for superior cutting. Their sharpness and longevity are unsurpassed, keeping your blade razor-sharp for longer. The blade’s precisely crafted teeth minimise expansion over prolonged usage, extending its lifespan.

A blade for the discerning craftsman, combining precision and durability

The CMT ORANGE TOOLS BLADE is the greatest woodworking tool for demanding perfection. Its high-quality carbide substance makes its blade durable. Its 24 carefully positioned teeth produce precise wood cuts easily.

The CMT Advantage: Quality by Design

CMT, a power tool giant, makes the CMT ORANGE TOOLS BLADE. Its orange colour and 10 x 10 x 0.1-inch measurements make it beautiful and functional. This blade is designed to operate with most table saws, making it adaptable for woodworking. The blade weighs 1.76 pounds despite its sturdy design, making it easy to control.

Get precise cuts every time with our guaranteed clean and accurate cuts

The laser-focused CMT ORANGE TOOLS BLADE is notable for precise cutting. No more workpiece damage or waste. Each blade in a one-package item is carefully manufactured to provide consistent and reliable performance in all your woodworking projects.

The CMT Orange Tools Blade represents precision, quality, and durability, not just a saw blade. Experience the difference this outstanding blade can make in woodworking. The CMT Orange Tools Blade ends poor cuts and begins a new era of woodworking perfection. If you value quality, pick CMT for woodworking.

Must Read – Best saw blade for composite decking

CMT ORANGE TOOLS BLADE First Hand Review Video

Video Source: wittworks

Pros:

- The CMT ORANGE TOOLS BLADE is made with high-quality carbide material, ensuring that it is durable and long-lasting.

- The blade’s optimized design with 24 teeth ensures precision cuts through wood.

- The blade’s unique style ensures compatibility with most table saws.

- The CMT ORANGE TOOLS BLADE is lightweight, making it easy to maneuver and control.

- The blade’s item package quantity is one, ensuring a reliable and efficient blade for your woodworking projects.

CORE FEATURE

| Material | Carbide |

| Brand | CMT |

| Item Dimensions LxWxH | 10 x 10 x 0.1 inches |

| Color | Orange |

| Number of Teeth | 24 |

| Style | Unique |

| Item Weight | 1.76 Pounds |

| Part Number | 240.008.04 |

| Product Dimensions | 10 x 10 x 0.1 inches |

Best table saw blade for ripping hardwood 2023-Complete buying Guide

When shopping for a table saw blade, there are several considerations to make. The right blade will depend on your individual woodworking needs and the specific type of hardwood you plan on ripping. Different blades are designed for different cutting tasks and your choice is important for ensuring the best results.

This guide will explain the different table saw blades available, how they differ from each other, and which particular blade is the best suited for ripping hardwood in 2023. It will cover topics such as blade types, tooth count, kerf size, materials used in construction, prices of blades, and whether or not carbide tips are necessary when ripping hardwood. Additionally, this guide will provide information about recommended brands so that you can make an informed decision when selecting a table saw blade that is right for your woodworking needs.

Photo Source: electrogardentools.com

Brief explanation of the purpose of a table saw blade

A table saw blade is designed to move at a high speed and make accurate, precise cuts in different types of wood. It is a vital piece of equipment for any woodworking shop or carpentry job, as it allows you to make accurate cuts with less effort.

Depending on the material you’re cutting and the desired end result, different types of blades will be required for each task. So it’s important to know what your specific needs are before choosing the right table saw blade.

When choosing a blade for your table saw, consider first what material you’re going to cut and how thick it is. For example, if you’ll be cutting hardwood that is more than ¾” thick, then you need an appropriate rip-blade specifically designed for such ripping tasks. For softwoods or other lighter materials like plywood or melamine, a combination or crosscut blade might offer more efficiency when cutting those materials with less tear-out.

Also consider the tooth profile (ATBR for rip vs ATB for crosscut), kerf widths and bore size should also be considered when selecting the best table saw blade based on your needs & preferences.

Factors to consider when choosing a table saw blade for ripping hardwood

Choosing the right table saw blade for ripping hardwood is a critical step in ensuring you get the most out of your woodworking projects. There are several factors to consider when selecting a new blade for your table saw so that you can get the best cut possible and reduce wear and tear on your saw. The following list of factors should be considered when shopping for a new ripping blade, including size, tooth count, tooth grind and material type.

- Size: The size of the blade is generally determined by the horsepower of the motor. As the motor increases in power, so does the size of the saw blade. Be sure to choose a blade that is designed to fit your specific saw model and motor size.

- Tooth Count: Blades come in different configurations with different numbers of teeth per inch (TPI). Generally speaking, lower TPI blades do a better job at cutting through hardwoods while higher TPI blades are better suited for softwoods or plywood. It’s important to note that higher TPI blades produce a smoother cut but they also wear out faster since they have more teeth coming into contact with each rotation of the blade.

- Tooth Grind: Teeth can be either flat-top or alternate top-bevel (ATB). Flat-top teeth provide an all-purpose cut suitable for both woods but will require more sanding after cutting is complete in order to obtain an even finish. ATB teeth produce smoother cuts than flat-top but will leave more residue on surfaces after cutting and require more frequent sharpening due to their intricate design.

- Material Type: Saws used for rip cuts should be made from either carbon steel or high speed steel (HSS) as these are stronger materials able to handle tougher hardwood cuts better than other materials such as aluminum oxide (AO). Carbon steel is less expensive than HSS but may not last as long when repeatedly used with thick material such as hardwoods whereas HSS provides greater durability.

Tooth count

The tooth count per inch of your blade is one of the essential characteristics that determine whether a blade is for cutting through plastics or in this case, hardwood. A higher tooth count per inch will be beneficial when cutting hardwood due to its ability to produce a finer finish. Hardwood requires more precision than other materials and the tooth count per inch of the blade should ideally be 28 TPI minimum, up to 100 TPI maximum.

Blades with fewer teeth may produce uneven cuts and cause splinters in hardwoods; therefore blades with 40 or 50 TPI work best for general purpose ripping. If you plan on using your table saw mainly for cutting hardwoods then you should go for blades with 80-100 TPI range.

Blade width

One of the most important factors to consider when purchasing a new table saw is the width of the blade. Generally, blades range from 0.5 inches to 3 inches in width and should be chosen according to the size and type of material you plan on cutting.

For ripping hardwood, a blade that has a width between 1/8 inch and 1/4 inch is best. This blade size allows for faster, more accurate cuts that promote stability and safety. The wider blades offer greater control over direction when making straight cuts and tend to create cleaner edges than smaller blades. In addition, these blades are less likely to be damaged by large pieces of wood as they can withstand more vibration due to their larger surface area.

For maximum precision and accuracy, it’s recommended that you buy blades specifically designed for ripping hardwood such as 10-inch diameter carbide-tipped sawblades which feature teeth arranged in:

- Alternate top bevel (ATB) configuration

- Combination tooth style (CTI)

ATB sawblades have alternating tooth patterns designed to cut through hardwood while creating clean edges while CTI sawblades offer a combination of both flat top grinds and ATB tooth patterns for an all-in-one cutting solution. Blades with these configurations will ensure your table saw produces precise cuts with minimal chipping on hardwood pieces such as oak, cherry, maple or hickory.

Blade material

The material of the blade is a critical factor when selecting a saw for hardwood ripping. There are several common materials used in table saw blades, each with its own advantages and disadvantages:

- Carbide – This is the strongest and most expensive type of blade material. It cuts through hardwood quickly and efficiently, but dulls more quickly than other types of blades.

- High Speed Steel – This type of blade is also very popular on table saws as it can handle hardwoods considerably better than other materials. It could last up to 20 times longer before needing to be replaced compared to a regular steel blade.

- Powdered Metal – This is a very common table saw blade available at lower prices than carbide or high speed steel blades. It offers good cutting power but may require more frequent sharpening compared to other alternatives as it dulls faster with use.

Hook angle

Choosing the right hook angle for cutting hardwood is critical. A hook angle is the degree of cutting influence in the blade’s tooth, usually specified in degrees. Hook angles typically range between 10 and 30 degrees (with finer cuts requiring smaller angles). The hook angle determines how efficiently and smoothly the blade will cut through hardwood.

Generally speaking, blades with larger hook angles are better suited for quick, aggressive cuts whereas those with smaller hook angles require more finesse and precision. Blades with a 15-degree hook angle produce medium cuts suitable for most soft to medium woods like pine or oak. If you plan on making long cuts through hardwood species such as maple or mahogany, we recommend a 20-degree hook angle that can provide sturdier and cleaner results.

For heavier-duty tasks, consider higher hook angles such as 25 or 30 degrees that are typically used when making deep pocket cuts or ripping thick pieces of lumber. Be aware though that increased rigidity also means increased resistance while cutting so consider this in terms of power consumption when selecting your blade size. A wider blade can come in handy in some specific scenarios so always double-check the specs before purchasing!

Plate thickness

When choosing a blade for ripping hardwood, one of the most important considerations is the plate thickness. Blades with high-grade steel and thicker plates (measured in 1/1000ths of an inch) are more rigid and less prone to vibration and flexing during use. If a blade flexes while in use it can create binding or uneven cuts that are unacceptable in precision woodworking projects.

Thicker blades also provide extra support when cutting thicker pieces of hardwood as well as resisting damage from large chunks if material that have been forgotten or left on the surface of the rip cut material.

III. Top recommended table saw blades for ripping hardwood 2023

So now that we’ve discussed the different types of blades and the features that you should consider, let’s take a look at some of the top recommended models of table saw blades for ripping hardwood available in the market for 2023. We hope this helps you decide which is best for your needs.

- Freud D1080X Diablo 10-Inch 80 Tooth ATB Effective Angle Hardwood Laminate Saw Blade – This blade from Freud is designed to provide clean cuts in solid wood and hardwood plywoods, as well as laminates like MDF and particleboard using an ATB effective angle design. The combination of the ATB grind and a negative hook geometry works to reduce noise while leaving smooth edges with minimal tear out on both sides of the cut. It also has a Perma-SHIELD coating to reduce friction, heat, gumming and wear.

- Oshlun SDS-0842 8-Inch 42 Tooth Stack Dado Set – The Oshlun SDS-0842 is a stack dado set that includes 2 outside blades, 2 chipper blades, 6 shims and an HSS configuration with finished edges made from C-4 micrograin carbide perfect for detailed cutting applications such as dados in hardwood thick stock or jointing workpieces. These blades have been treated with anti-kickback shoulders for added safety when ripping wood on your table saw.

- Forrest WW10407125 Woodworker II 10-Inch – This 10″ blade from Forrest has a thin kerf design that helps reduce waste when cutting your hardwoods; it also has a triple chip grind (TCG) configuration with alternating bevels for sliced cuts in hardwoods or laminates like particle board or melamine up to 1/2″ thick without blowing out or splintering the material on exit sides. With 40 tooth counts available it can fit both 5/8″ in 1″ arbors giving plenty of options when mounting to most types of table saws currently available on the market today.

Overview of the best blades available in the market

When it comes to choosing the best table saw blades for ripping hardwood in 2021, the options may seem overwhelming. Because of this, we have created a comprehensive guide about the different types of blades available on the market and what makes them stand out from other options.

We have provided detailed information about the features, pros and cons associated with each blade to help you determine which type would best suit your needs. This guide will also provide an overview of different manufacturers and brands so you can find the right product at the right price.

With all these factors taken into consideration, hopefully you can make a well-informed decision when selecting a new table saw blade for your next workshop project.

Advantages and disadvantages of each blade

When choosing a blade for your table saw, it is important to understand the advantages and disadvantages of each type. Hardwood ripping blades typically have either alternating top bevel (ATB) teeth, or flat top grind (FTG) teeth. A combination blade will also have both types of teeth.

Alternating Top Bevel Blades

Alternating Top Bevel blades are designed to cut wood fibers cleanly and quickly by alternating bevels on each tooth. The slight angle of the ATB tooth does a better job of dispersing sawdust, resulting in smoother cuts in hardwood materials.

The main disadvantage of an ATB blade is it produces more heat during cutting than a Flat Top Grind blade. This can create some burning on the surface of the material, and may cause fraying when turning corners. Additionally, they don’t form well to tight radii shapes because the angle at which they cut causes tearing in the wood fibers.

Flat Top Grind Blades

Flat Top Grind blades offer a more precise cut than an ATB blade due to their higher rake angles that produce less friction with the material being cut when sharper turns are required. FTG blades will also save you time since they can often speed through materials faster than an ATB blade because they can remove material quickly with minimal heat build up while reducing splintering and tear-out. However, their flat design means that sawdust won’t disperse as quickly from these blades as it would from an ATB blade producing less dust extraction from your table saw experiences operating conditions when cutting hardwood materials with these types of blades compared to other types due to increased noise level and resistance when cutting through certain woods.

Combination Blades

Combination blades offer all of the benefits described above for both ATB and FTG teeth without sacrificing performance with either type of tooth design allowing smooth finish on both hardwoods and softer woods such as plywoods, veneers etc. These blades are very versatile but don’t provide any specific advantage over either sole ATB or FTG tooth designs, since each has its own unique attributes in terms of speed, strength and cutting quality producing excellent results particularly when ripping longer lengths or thicker stock lumber materials such as oak or maple among others.

How to maintain and sharpen a table saw blade

Proper maintenance and sharpening of table saw blades is essential for safe and efficient operation. Below, we outline the steps for taking care of your blades so you can ensure your projects are accurate, clean and lasting.

First, start by inspecting each blade for any damage or wear. Raised sections, worn teeth or chips in the cutting edges indicate that it is time for sharpening or replacement, depending on the severity. Always use the appropriate guards with all table saw blades to minimize contact with these edges and protect yourself from harm.

For general maintenance and upkeep, you should have a designated storage place away from dust, dirt and moisture accumulation where you can keep track of each blade’s condition and to make sure they are ready when needed. If storing multiple blades at once in a case, be sure to separate them according to size with spacers between them to prevent bending when stacked on top of one another.

Before attempting sharpening procedures on your blades you should follow safety precautions including wearing protective eyewear, gloves and hearing protection while operating power tools that can be hazardous if used incorrectly or without proper care as stated in many manufacturer’s instructions. For manual sharpening using files or stones you may want to wear an additional dust mask for lung protection from particles caused by grinding materials off the blade surfaces.

When running a circular saw table make sure all protective guards are in place before beginning the cut in order to keep hands safely away from moving parts as well as debris created during operation of the machine. Always use the correct blade speed rated for specific cutting applications according to recommended speed range listed in owner’s manuals. This is important because using too quick of an rpm will cause excessive heat buildup that can lead to blade failure prematurely due its increased chances overheating while lower speeds will not provide adequate performance levels resulting degraded cutting results while still putting additional strain on motor components over time as well longer times needed complete jobs due reduced efficiency levels encountered slow rpms being employed when cutting various types material such hardwoods softwoods plastics composites laminates melamine metal woodworking products veneers etc…

Photo Source: homedepot.com

Steps to keep the blade in top condition

Once you’ve found the perfect table saw blade for your hardwood ripping needs, keep it in top condition by taking a few easy steps. You should pay careful attention to the following tips when installing and using your new table saw blade:

- Be sure to secure the saw blade tight. Use a wrench or other tool if needed. If you secure it too tightly, however, avoid using excess torque as this can damage the blade and affect its performance.

- Make sure to leave a minimum 1 mm clearance between the body of the blade and any adjacent pieces that can interfere or cause friction when in use.

- Always ensure that the teeth are free of rust and debris before each use, as this increases cutting efficiency and decreases wear on the teeth over time. A tooth brush or small soft brush is suitable for cleaning rust off teeth prior to use.

- Never allow anything but wood – either hardwood or softwood – to come into contact with your new blades as this could cause damage to both woods, depending on the material used for cutting it and the material about to be cut with it. Also make sure not to expose your saw blades unnecessarily to liquids or moisture as this could corrode them over time if left unchecked too frequently for long periods of time during woodworking projects involving lots of water exposure such as lamination etc..

- Always remember that running any saw blade at higher speeds certainly increases performance but also affects its durability due its elevated mechanical stress which results from faster rotations per minute (RPMs). If possible, reduce RPMs whenever possible while still achieving desired results while in use by adjusting accordingly according gear reduction ratios or those available within specific saw models like belt drive options etc..

How to sharpen a dull blade

Sharpening a dull table saw blade is an essential part of maintaining your saw’s performance in the long run. A dull blade is inefficient and can cause serious injury if used improperly. It requires some skill, special tools, and plenty of patience, but it isn’t hard to do yourself.

First you should inspect the saw blade for any visible damage. The blades should be free of chips, cracks, or discolorations. If they show any signs of damage they should be replaced immediately.

To sharpen the teeth of your saw blade, you will need to purchase a file set specific to the tooth pitch size of your blade (made for blades with 4 – 10 teeth per inch). Using a light oil or honing solution, apply it to all areas before beginning to sharpen. With a medium to fine grade file in hand, rest the diamond surface against the corner of each tooth and draw it across paying careful attention not beveling too much – being conservative with your file strokes is necessary so that no excessive metal removal takes place. Repeat this on each tooth alternating sides so as to ensure even sharpening all around each face until they are all cleanly producing shavings off both sides when cut into wooden boards surface correctly.

Once finished use 400-grit sandpaper on a flat board and take one last pass going directly across each tooth’s face twice at 90 degrees in order could eliminate any excess burrs or swarf left after filing followed by 0 grit wet/dry paper which helps refine and further de-burrs replace again at 180 degrees doing two more passes until each side has been treated as such (keeping pressure constant). This will help restore cutting performance by leaving every tooth perfectly sharpened every time – ready for use!

Conclusion

Choosing the best table saw blade for ripping hardwood is ultimately up to you and your specific needs. There are a variety of factors that could affect which saw blade is right for your particular project, such as size, construction materials, tooth count, and pricing.

Ultimately, it’s important to understand what the different characteristics mean and how they affect the performance of the saw blade. Remember that sharper teeth make it easier to cut through hardwood with minimal effort or resistance, and fewer teeth help prevent binding during a rip. Be sure to also look at tooth arrangement and carbide quality when looking for a good saw blade.

With these tips in mind, you should be able to find an excellent table saw blade that will suit your needs perfectly!

FAQ’S

What is the best table saw blade for ripping hardwoods?

The best table saw blade for ripping hardwoods depends on various factors such as blade diameter, TPI (teeth per inch), and kerf design. Generally, a 24-40 TPI saw blade with a large diameter and a low kerf design is ideal for ripping hardwoods.

What is the best saw for ripping wood?

A table saw is considered as the best saw for ripping wood, but a circular saw or track saw can also be used for this purpose.

What is the best table saw blade for ripping softwood?

The best table saw blade for ripping softwoods is typically a blade with a high TPI, such as 60 or 80 TPI, and a low kerf design.

What circular saw blade is best for hardwood?

A circular saw blade with a low TPI, such as 40 or 60, and a durable construction is considered the best for cutting hardwoods.

How many TPI do you need for hardwood?

For hardwoods, a TPI of around 40-60 is considered appropriate.

What is a 120 tooth saw blade used for?

A 120 tooth saw blade is typically used for making fine cross cuts and finish cuts on softer materials such as melamine, veneers, or laminates.

What is the best tool to cut hardwood?

A table saw or a track saw is considered as the best tool for cutting hardwoods.

How many teeth is best for a table saw blade?

The number of teeth on a table saw blade varies depending on the type of material and the desired outcome, but a 40-60 TPI is commonly used for hardwoods.

What is a 90 tooth saw blade used for?

A 90 tooth saw blade is typically used for making fine cross cuts and finish cuts on softer materials such as melamine, veneers, or laminates.

How do you rip thick wood on a table saw?

To rip thick wood on a table saw, you need to make sure that the blade is sharp and properly aligned, use a rip fence and push stick for stability and safety, and adjust the blade height and speed to match the thickness and hardness of the wood.

Michael Lilli is the author and CEO of sawbladetown.com and Informative Website. With over 10 years of experience in the saw blade industry, Michael has become a leading expert in the field. He is dedicated to helping professionals and hobbyists alike find the perfect saw blade for their projects. Through his informative website and writing, Michael shares his knowledge and expertise on everything from saw blade anatomy to advanced techniques and safety precautions. His passion for saw blades and commitment to helping others has made him a trusted resource in the industry.