Struggling to find the best thin kerf table saw blade? You’re in luck! This guide contains all the information you need to make an informed purchase and get the most out of your table saw. From types of blades to essential features, learning more about this tool and what it can do for you is essential for getting great results.

Best thin kerf table saw blade 2023

- CMT ORANGE TOOLS Orange Chrome Ripping Blade (Editor’s Pick)

- Freud LU84R011: 10″ Combination Blade (Best Overall)

- Amana Tool MA10050 Combination Blade(Budget Friendly)

- Norske Tools NCSBT150C Saw Blade

- Freud LU74R010 Cut-Off Saw Blade

- Overpeak Circular Saw Blade

- Forrest WW10407125 Saw Blade

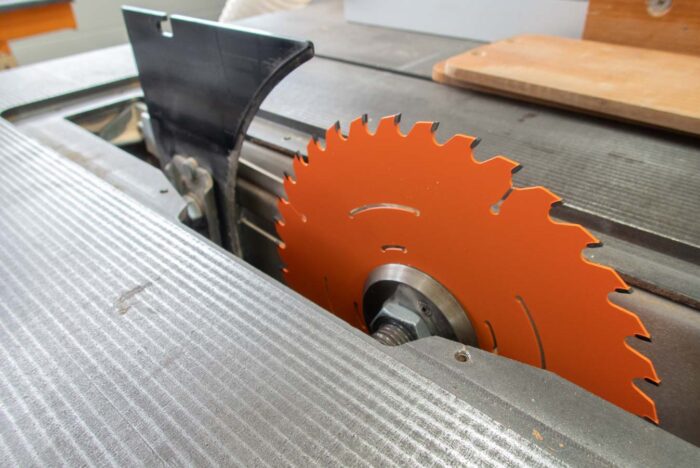

1) CMT ORANGE TOOLS Orange Chrome Ripping Blade

Cutting-Edge Design: This blade’s circular saw design and silver finish make it professional and compatible with most table saws. This blade exceeds advanced woodworkers’ needs.

Introducing Orange CMT Tools Ripping Blade: Every Cut Precision

The CMT ORANGE TOOLS Ripping Blade cuts wood precisely best. This 10-inch diameter, 5/8-inch bore circular saw blade fits numerous chop mitre and table saw machines. The 24 flat teeth and 0.126-inch kerf make it suitable for tearing.

Carbide Power Releases

The CMT ORANGE TOOLS Ripping Blade’s carbide makes it effective. Carbide is strong and durable. After prolonged use, this sharpens the blade for accurate cuts. Silver shine helps any cutting project look professional.

Compact and Lightweight

The CMT ORANGE TOOLS Ripping Blade weighs 449 grams (15.8 ounces) and measures 6.25 x 0.82 x 0.51 inches. Transporting, storing, and handling it has never been easier. This blade is your go-to for cutting, pro, or DIY.

Conclusion

Precision cutting enhances woodworking with the CMT Orange Tools Ripping Blade. Its high-strength carbide, flat teeth, and compact design make it the best wood-ripping tool. This blade ensures accurate and reliable cuts for DIYers and professionals. Select precision with the CMT Orange Tools Ripping Blade.

Must Read – Best combination table saw blade

CMT ORANGE TOOLS Orange Chrome Ripping Blade First Hand Review Video

Video Source: wittworks

Pros:

- High-strength carbide material for long-lasting sharpness

- Lightweight at 449 grams or 15.8 ounces for easy handling

- Compact size of 6.25 x 0.82 x 0.51 inches for easy storage and transport

- 24 flat teeth and 0.126 inch kerf for precise ripping applications

- Sleek silver color for a professional look

CORE FEATURE

| specifications | Application: Ripping |

| specifications | Materials: Wood |

| Material | Carbide |

| Brand | CMT ORANGE TOOLS |

| Item Dimensions LxWxH | 6.25 x 0.82 x 0.51 inches |

| Color | SILVER |

| Number of Teeth | 24 |

| Style | Circular Saw |

| Item Weight | 449 Grams |

| Part Number | 285.624.10 |

2) Freud LU84R011: 10″ Combination Blade

The Freud LU84R011’s multi-colored appearance makes cutting equipment look professional. Its 10-inch 50-tooth ATB combination saw blade works with most saws, making it adaptable for cutting applications. The blade’s well-balanced, anti-vibration design improves accuracy and reduces strain. Its high-density construction and Perma-SHIELD coating ensure durability and protection. This blade always exceeds expectations, whether you’re a DIYer or a professional with a busy workshop.

Freud LU84R011: 10-Inch Combination Blade—Your Professional Companion

The Freud LU84R011 10-inch combo blade is designed for professionals. A mix of high-quality materials ensures great cutting performance and longevity. Freud, a power tool giant, offers this multi-colored blade with 50 teeth for tearing and crosscutting.

Versatility Unmatched

When working with wood, laminate, and melamine, this blade shows its versatility. Design ensures smooth, clean cuts that require little sanding or finishing. Top-grade materials and 50 teeth make it easy to cut even the toughest tasks.

Durability is a crucial attribute of the Freud LU84R011 blade. Its high-quality materials allow it to withstand heavy use without losing its sharpness. It’s suitable for experts and DIYers due to its simplicity. It’s lightweight and easy to store at 1 pound and 1 x 1 x 1 inches.

Conclusion

The Freud LU84R011 is a top-notch combo blade for professional use. Its superior materials, 50 teeth, and adaptability make it the best ripper and crosscutter. This blade, easy to use and durable, makes smooth, clean cuts without sanding or finishing, setting a new level in precision cutting instruments.

Must Read – Best concrete saw blade

Freud LU84R011: 10″ Combination Blade First Hand Review Video

Video Source: WoodWorkWeb

Pros:

- 50 teeth for smooth, clean cuts

- Versatile tool that can handle a range of cutting tasks

- Made of a high-quality blend of materials for superior durability

- Lightweight at 1 pound for easy handling and transportation

- Manufactured by Freud, a renowned brand in the power tool industry

CORE FEATURE

| Material | Blend |

| Brand | Freud |

| Item Dimensions LxWxH | 1 x 1 x 1 inches |

| Color | Multi |

| Number of Teeth | 50 |

| Item Weight | 1 Pounds |

| Domestic Shipping | Item can be shipped within U.S. |

| Part Number | LU84R011 |

| Product Dimensions | 1 x 1 x 1 inches |

| Size | One Size |

3) Amana Tool MA10050 Combination Blade

1. Precision Cutting with 50 Teeth

This blade has 50 teeth for accurate, clean cuts. This blade gives woodworkers and professionals the precision they need.

2. A sleek, professional look

The sleek black blade gives your instruments a professional look. When you want top results, your gear should reflect that.

3. Multipurpose Circular Saw

The circular saw style works with most saws, making it versatile. This is the perfect tool for DIYers and pros.

Amana Tool MA10050 Combination Blade: Carbide-Tipped Champion

Designed for excellent cutting, the Amana Tool MA10050 Combination Blade is made of high-quality carbide for durability. Its 5/8 bore makes it compatible with many circular saw machines, making it versatile for tasks. This blade rips and crosscuts well.

Power of Carbide Tipped Material

The carbide-tipped substance is strong and durable. Professionals who expect cutting excellence choose it. Your projects deserve the finest.

Precision and Portability

This 13.5 x 11.5 x 0.26-inch blade is the right size and convenience. Easy to keep and travel, it’s always ready for cutting. Its lightweight 0.77 grams (0.027 ounces) construction makes it easy to handle.

The Amana Tool MA10050 Combination Blade is a versatile and reliable tool for professionals seeking exceptional cutting solutions. Its carbide-tipped material and 50 teeth ensure durability and precision when tearing or crosscutting. Its tiny size and lightweight construction make it essential for mobile professionals, providing high-quality cutting. Amana Tool combines precision and durability to elevate projects.

Must Read – Best dado blade for table saw

Amana Tool MA10050 Combination Blade First Hand Review Video

Video Source: Unemployed Redneck Hillbilly Creations

Pros:

- Carbide tipped material for durability and long-lasting sharpness

- 50 teeth for smooth and precise cuts

- Versatile tool that can handle both ripping and crosscutting applications

- Lightweight at 0.77 grams or 0.027 ounces for easy handling

- Compact size of 13.5 x 11.5 x 0.26 inches for easy storage and transport

CORE FEATURE

| specifications | Carbide Tipped |

| specifications | 5/8 Bore |

| Material | Carbide |

| Brand | Amana Tool |

| Item Dimensions LxWxH | 13.5 x 11.5 x 0.26 inches |

| Color | Black |

| Number of Teeth | 50 |

| Style | Circular |

| Item Weight | 0.77 Grams |

4) Norske Tools NCSBT150C Saw Blade

The Norske Tools NCSBT150C Saw Blade has the innovative ATB tooth grind. This advanced technology cuts quickly and durably, making it excellent for various applications. This blade can make a DIY masterpiece or manage a busy workshop meet your demands and exceed your expectations. Any professional carpenter requires its speed, durability, and modern design.

Explore Norske Tools Twin Pack NCSBT150C Saw Blade

Still more! Flexible for all cutting needs, the Norske Tools NCSBT150C Saw Blade in a twin set. This twin package includes a 10″ x 28T framing blade and a 10″ x 60T finish blade for their respective uses. The blades smoothly cut plywood, wood, and MDF. The ATB tooth grind and 10-15 degree hook angle make them good tearers and crosscutters.

Craft meets convenience

The Norske Tools NCSBT150C Saw Blade twin pack is powerful and easy to operate. These blades operate with many circular saw machines, simplifying your operations. Their silver finish elevates any cutting project, making your tools seem lovely as well as functional. Trusted power tool maker Norske Tools makes these blades.

Customized Precision for Every Task

The twin-pack Norske Tools NCSBT150C Saw Blade excels in many cutting tasks. While the frame blade cuts coarsely, the finish blade cuts precisely and silkily. This twin pack has the essential tools for every cutting operation for woodworkers and DIYers.

Conclusion

The Norske Tools NCSBT150C Saw Blade twin pack is perfect for all cutting applications. Its ATB tooth grind, hook angle, and circular saw compatibility make it the best for ripping and crosscutting. Experts and DIYers love the twin pack because it always includes the right gear. The Norske Tools NCSBT150C Saw Blade twin set revolutionises woodworking with precision and power.

Must Read – Best jig saw blade for plywood

Norske Tools NCSBT150C Saw Blade First Hand Review Video

Video Source: Sawblade.com

Pros:

- Twin pack includes a framing blade and a finish blade for versatility

- ATB tooth grind with a 10-15 degree hook angle for precise cuts

- Compatible with a range of circular saw machines

- Designed to cut a range of materials, including plywood, wood, and MDF

- Manufactured by Norske Tools, a trusted brand in the power tool industry

CORE FEATURE

| specifications | 10″ Trade series twin pack |

| specifications | 10″ X 28T framing & 10″ X 60T finish |

| specifications | Atb tooth grind with 10 – 15 Degree hook angle |

| Material | Plywood,Wood,Mdf |

| Brand | Norske Tools |

| Item Dimensions LxWxH | 10 x 0.3 x 10 inches |

| Color | Silver |

| Style | Modern |

| Item Weight | 2.9 Pounds |

5) Freud LU74R010 Cut-Off Saw Blade

Professional Freud LU74R010 Cut-Off Saw Blade. High-quality materials make this blade durable.

Extreme Precision, 80 Teeth

Freud LU74R010’s 80 teeth cut neatly and accurately. This blade slices and crosscuts perfectly.

Basic Versatility

Freud LU74R010 Cut-Off Saw Blade is multitasking-friendly. This blade is precise and durable for DIY and pro use.

Top Compatibility

This blade fits numerous circular saws. Adjusting tools lets you concentrate on art.

Elegant and Usable

The multi-colored Freud LU74R010 enhances cutting projects beyond its performance. Besides a tool, it conveys professionalism.

Freud Precision Partner LU74R010 Cut-Off Saw Blade

Professionals require Freud LU74R010 Cut-Off Saw Blade accuracy. The 80-teeth design, superior material blend, and compact size make it suitable for crosscutting. Durability, use, and perfect cuts every time.

Freud LU74R010 Cut-Off Saw Blades survive long and work precisely.

Must Read – Best metal cutting circular saw blade

Freud LU74R010 Cut-Off Saw Blade First Hand Review Video

Video Source: Sawblade.com

Pros:

- 80 teeth for smooth and accurate cuts

- High-quality blend of materials for durability and long-lasting sharpness

- Compact size of 6.25 x 0.82 x 0.51 inches for easy storage and transport

- Lightweight at 0.15 pounds or 2.4 ounces for easy handling

- Compatible with a range of circular saw machines

CORE FEATURE

| Material | Blend |

| Brand | Freud |

| Item Dimensions LxWxH | 6.25 x 0.82 x 0.51 inches |

| Color | Multi |

| Number of Teeth | 80 |

| Item Weight | 0.15 Pounds |

| Part Number | LU74R010 |

| Item Weight | 2.4 ounces |

| Product Dimensions | 6.25 x 0.82 x 0.51 inches |

| Size | One Size |

6) Overpeak Circular Saw Blade

Craftsmanship drives the Overpeak Carbide Circular Saw Blade. This blade is made of high-quality carbide, ensuring durability and lifespan. This eliminates frequent replacements, saving time and money.

Flexible Compatibility

Its adaptability makes this circular saw blade stand out. It’s compatible with many circular saw machines, making it ideal for many cutting operations. Engineered or traditional wood, this blade can handle it.

Sleek Design for Easy Recognition

Identifying tools quickly is essential in a busy workshop. The Overpeak Carbide Circular Saw Blade’s blue colour helps it stand out in any workspace. This blade sticks out, so no more digging through a bunch of tools.

Quiet, stable operation

Nobody likes cutting tools’ ear-piercing noise. The Overpeak Carbide Circular Saw Blade makes operating quieter and more pleasant. Its steadiness during cutting ensures accuracy and efficiency.

Compact and Lightweight

Tool handling is important whether you’re a pro or a DIYer. The size and weight of this circular saw blade are unknown, making it easy to use. You won’t tyre easily over long projects.

Conclusion

your essential woodworking companion

The Overpeak Carbide Circular Saw Blade is a solid woodworking tool. High-quality carbide and 80 precision teeth for clean, accurate cuts. Its elegant appearance, silent operation, compatibility with various circular saw machines, and ergonomic build make it ideal for professionals and hobbyists.

Maintain high-quality woodworking tools. Buy the Overpeak Carbide Circular Saw Blade to improve your projects’ precision and longevity. Woodworking quality replaces frustrating cuts.

Must Read – Best miter saw blade

Overpeak Circular Saw Blade First Hand Review Video

Video Source: Catus Maximus

Pros:

- Carbide material for durability and long-lasting sharpness

- 80 teeth for precise and clean cuts

- Compatible with a range of circular saw machines

- Ideal for cutting a range of materials, including engineered wood and wood

- Manufactured by Overpeak, a trusted brand in the power tool industry

CORE FEATURE

| Package Dimensions : | 11.89 x 10.94 x 0.35 inches; 1.63 Pounds |

| Material | Carbide |

| Brand | Overpeak |

| Color | Blue |

| Number of Teeth | 80 |

| Style | 10INCH 80T-2023 |

| Compatible Material | Engineered Wood, Wood |

7) Forrest WW10407125 Saw Blade

The Forrest Carbide Circular Saw Blade is durable and made of high-quality carbide. Durability ensures it can tolerate heavy use without losing edge. This blade is long-lasting, thus no more blade replacements.

Style and Function

The Forrest Carbide Circular Saw Blade performs well and beautifies your workplace. The sleek silver colour and sophisticated design enhance your workspace. Its small size (11 x 11 x 1 inches) and light weight (2.18 pounds) make it easy to move.

Quieter Operation

This blade is precise, stylish, and quiet, making it ideal for work. Its steady cutting makes it excellent for DIY and professional woodworking projects.

The Ultimate Woodworking Companion: Forrest WW10407125 Saw Blade

Woodworkers seeking the best cutting tools should choose the Forrest WW10407125 Saw Blade. Carbide makes this blade durable and long-lasting. It’s ideal for crosscutting with 40 teeth for clean, precise cuts.

Cutting-Edge Toothstyle

The tooth style of the Forrest WW10407125 Saw Blade is notable. Its 15° ATB teeth and 20° face hook ensure perfect cuts every time. This blade’s silver polish and modern shape give any project a professional look. Its quality comes from Forrest, a trusted woodworking brand.

Precision and Flexibility

The Forrest WW10407125 Saw Blade cuts smoothly and accurately every time. The blade’s 40 teeth and carbide material maintain precision over time. This blade works well with wood and other materials.

Conclusion

Woodworking requires precision and reliability, which the Forrest WW10407125 Saw Blade provides. No matter the material, its carbide structure and 40 teeth assure precise and clean cuts. The sleek teeth appearance and functionality make it a tool loved by pros and DIYers. Invest in the Forrest WW10407125 Saw Blade for years of accurate, high-quality cuts.

Must Read – Best miter saw blade for fine cuts

Forrest WW10407125 Saw Blade First Hand Review Video

Video Source: The WoodCrafterThe WoodCrafter

Pros:

- Carbide material for durability and long-lasting sharpness

- 40 teeth for precise and clean cuts

- Ideal for cutting a range of materials, including wood

- Modern style and silver color add a sleek and professional look to any cutting project

- Manufactured by Forrest, a trusted brand in the woodworking industry

CORE FEATURE

| specifications | Tooth style:15° ATB, 20° face hook |

| Material | Carbide |

| Brand | Forrest |

| Item Dimensions LxWxH | 11 x 11 x 1 inches |

| Color | Silver |

| Number of Teeth | 40 |

| Style | Modern |

| Item Weight | 2.18 Pounds |

| Part Number | WW10407125 |

Best thin kerf table saw blade 2023-Complete buying Guide

Here are some important things to consider when buying a thin kerf table saw blade:

- The type of blade – rip, crosscut, combination, etc.

- The size of the blade – diameter, kerf, number of teeth, etc.

- The material of the blade – carbide, steel, etc.

- The blade’s cutting performance – speed, accuracy, etc.

- The blade’s anti-kickback features – riving knife, splitter, etc.

Welcome to the Best Thin Kerf Table Saw Blade Buying Guide for 2023. This guide aims to help you make a smarter purchase when looking for a thin kerf saw blade that’s suitable for your applications. As the availability of different sizes, styles, and options vary among manufacturers, it can be difficult to know what kind of saw blade is best suited for your project or budget. To that end, this guide provides an overview of features found on thin kerf saw blades and offers suggestions on how to find the right saw blade for your specific needs.

We’ll start off by discussing why thin kerf blades are important before moving into a discussion about types of saw blades available including:

- Frammels

- Stacked dado sets

- Radial arm saws

- Combination blades

Finally we’ll discuss some tips and tricks for making sure you get the best-performing table saw blades along with potential health and safety considerations related to working with table saws in general.

Photo Source: finewoodworking.com

Explanation of thin kerf table saw blades

A thin kerf table saw blade is a type of circular saw blade designed for table saws. It features a narrower cutting width than a full-kerf, allowing it to make more efficient cuts and saving both material and energy. The blades are specifically optimized for use with table saws and can make cross cuts, rip cuts, and miter cuts with precision. Thin kerf blades also have the advantage of being easier to install than standard-kerf blades.

When selecting a thin kerf table saw blade, there are several characteristics that you should consider:

- The number of teeth on the blade will dictate how fast or slow light it will cut as well as the amount of material that it can remove per revolution.

- The thickness of the kerf determines how much resistance there will be while cutting into the material which affects accuracy and speed.

- Additionally, there are tradeoffs to be made between heat buildup which affects the longevity of the blade, and the quality and finish that is left after cutting through different types of woods.

Importance of choosing the right blade

Choosing the right table saw blade is vitally important for achieving accurate cuts and a better finish. The wrong blade may cause problems such as burning on the wood’s surface, splintering, chipping or ruining the wood. A thin kerf blade is a very popular choice due to its light weight which can reduce vibrations and extending its lifetime longer than other blades.

The key features to consider when selecting the best thin kerf table saw blades for you include:

- Blade Width and Kerf: The width of a blade will determine how wide of a cut it can make in your workpiece. A thinner kerf (width of cut) requires less effort to make the cuts, resulting in faster cutting speeds, less material wastage, and more efficient use of your motor’s power output.

- Tooth Design: Tooth design varies between various blades, offering various advantages depending on your project type. Alternating top bevel (ATB) or combination (TCG) are most common versions – with ATB designs providing cleaner crosscuts while TCG giving better results when ripping thick stock material with large “free” grains such as plywood or chipboard.

- Tooth Count & Blade Diameter: Both of these factors influence how quickly your saw will cut through the stock material, but too many teeth can also cause more splintering upon exit which increases sanding time post-workpiece completion while too few teeth may lead to rough finish at slower speeds. Optimal selections depend mainly on material hardness, type and thickness being used in projects; however medium tooth counts (48-100T) with 8-12” diameter blades typically offer good balance between speed and finished quality across most woods & other soft materials.

Characteristics of a Good Thin Kerf Table Saw Blade

When selecting a thin kerf table saw blade, it is important to consider a few key characteristics. A good blade should be able to provide the best combination of speed, performance and accuracy for your particular needs.

First, consider the number of teeth on the blade. A high-tooth count means smaller kerf width and an easier, smoother cut. The size of the plate is also a factor – thinner plates tend to vibrate less than thicker plates and can produce more accurate results. It’s important to note that some thin kerf blades may require specific arbors or adapters so they fit onto the saw, so be sure you are aware of this before purchasing.

When selecting a thin kerf blade, look for one that is made with premium-grade materials such as carbide steel or high-speed steel; these materials help ensure accuracy and longevity in your cutting jobs. You may also want to look into whether or not the blade features computer-controlled construction techniques – these blades have seen improvements in cutting accuracy and performance due to advances in manufacturing technology over time. Lastly, determine if you need a specific type of tooth design – some blades are specifically designed for ripping while others are more suited for crosscuts.

Blade thickness

Blade thickness, or “kerf,” is one of the most important factors to consider when purchasing a table saw blade. Kerf refers to the thickness of the material being cut and is used to determine size and power needs for a particular saw blade. When shopping for a table saw blade, it’s important to understand kerf size and how it relates to the type of cut you’ll be making.

Kerf sizes range from 1/8″ to 3/8″, with 1/2″ and 3/4″ blades designed for heavier-duty applications. Generally speaking, a smaller kerf is better suited for finer work as it requires less power than thicker blades. On the other hand, thicker kerf blades make safer and smoother cuts on rough material. For general purpose projects, a thinner blade with around 1/8″ to 1/4″ kerf size should suffice.

There are also specialized blades available that include thinner profile options like “ultra-thin kerfs”. These require less power input from your saw motor but still provide clean cuts in wood materials without burning or heat-inducing friction. Ultra-thin kerfs provide an efficient cutting option for woodworkers using both standard home shop tools as well as full commercial table saws in production shops.

Blade tooth count

When choosing a thin kerf table saw blade, the number of teeth on the blade is one of the most important factors to consider. The different sizes of teeth determine the speed and finish quality you can expect from a cut. Blades with fewer teeth will cut faster but leave coarser finishes while blades with more teeth provide slower cuts but create smoother finishes.

Common tooth counts range from 24 to 100, and it is important to select a blade that’s suited for the intended application. For general purpose usage, a combination blade with around 40-60 teeth may be ideal. If you are looking for ultra-fine cuts, opt for a blade with 80-100 teeth. Alternatively, blades with fewer than 20 teeth are available for rapid ripping operations such as cutting thick timber boards in half or making fast crosscuts in sheet stock material.

Blade material

The material used in a blade determines the speed that the saw cuts and how durable it is. There are 3 primary types of materials used to manufacture table saw blades:

- Carbide: Made from tungsten and carbon, carbide is an incredibly hard and heat resistant metal. This makes it an ideal choice for cutting through tough materials, such as hardwoods and metal. Carbide blades are showcased by their long life, but be aware that they can be quite expensive.

- High-speed steel (HSS): This metal provides longer edge life than regular steel but will dull more quickly when cutting harder woods or other materials. The price point for these blades is in the mid-range. They are often combined with a softer alloy to make them heat-resistant so that they can also cut mild metals without significant damage to the blade.

- Soft metal alloy: These blades tend to be less expensive than the others, but can only really handle soft woods or thin pieces of metals such as aluminum or copper. When used with thinner workpieces like plywood or laminate, these blades should perform well; anything thicker will push them beyond their limits.

III. Factors to Consider When Buying a Thin Kerf Table Saw Blade

When choosing a thin kerf table saw blade, there are several factors to consider. Some features can help you make the most of your investment in a blade, while others may not matter as much. Considering each factor not only helps you purchase the best table saw blade for your needs but also improves the accuracy and performance of your saw in general.

- Blade Diameter & Bore Size: Table saw blades are available in different diameters and bore sizes. When purchasing a blade, it is important to choose one that is compatible with the specifications of your current table saw model. Generally, larger diameter blades can provide more powerful and accurate cuts, while smaller blades can be more maneuverable on certain materials like plywood.

- Kerf Width: The kerf width refers to the thickness of the groove left behind while cutting with a table saw blade. A standard-width kerf is usually wider than that of a thin-kerf blade, allowing for less material to be removed when cutting longer stock pieces like boards or panels. Thin-kerf blades have minimal resistance when cutting through material because they require less material removal than their standard-width counterparts – this is why these types of blades minimize waste and increase efficiency by improving accuracy too!

- Tooth Number & Pattern: The tooth configuration determines how aggressive or smooth your cut will be but also affects other factors such as speed and accuracy. Blades with fewer teeth tend to leave behind rougher edges on hardwoods while those with more teeth (like Alternate Top Bevel or Triple Chip Grinding) make cleaner crosscuts on both hardwoods and softwoods – something useful when using jigsaws or miter boxes. Choose depending on the type(s) of cut you plan on making most often as well as what type of material will mostly be used (hard/soft woods). Additionally, look at how far apart each individual tooth is placed since that dictates how deep they will leave trenches when making crosscuts (greater distances between teeth=deeper trenches). The number and size of teeth set may change depending upon whether ripping or crosscutting operations are being performed so make sure you look into this when selecting an appropriate table saw blade for yourself!

Purpose of the blade

The purpose of your table saw blade dictates the type of cut you are looking to accomplish as well as the shape, number, and size of teeth it should have. Different blades offer different performance characteristics and create different types of cuts in your workpieces. Generally, there are two primary purposes for a table saw blade: rip cuts and crosscuts.

Rip Cut Blades: Rip cut blades are made for cutting along the grain in long-grain lumber. This is the most common type of cut used on a table saw, so they typically feature an aggressive tooth pattern designed to quickly remove material across the entire width of a board. Rip blades usually feature flat top teeth that alternate between left-handed and right-handed bevels or alternating top bevels that provide very clean edge quality. They can also have a varying degree of positive “hook” angle depending on the depth and width of your dado set or when making non-through cuts with your regular blade (such as when rabbeting or dadoing).

Cross Cut Blades: Crosscut blades are designed for cutting perpendicular across a workpiece’s grain at 90° angles. These blades will typically have more teeth than rip cut blades allowing for smoother, cleaner edge finishes but sacrificing some speed when cutting across grain fibers. Alternating top bevel (ATB) style teeth are most common on crosscut blades as they provide great edge quality while still having aggressive enough tooth geometry to easily remove wood fibers without tear out or deflection in thinner material like plywood or particle board.

Photo Source: festoolownersgroup.com

Compatibility with your table saw

When choosing a table saw blade, it is important to consider its compatibility with the model of the saw you are using. The majority of modern table saws are equipped with either 10- or 12-inch blades, so check what size is compatible with your saw before you buy. It’s also important to ensure that the blade fits securely on the arbor, so check its size.

Also, check the maximum RPM (revolutions per minute) rating of your saw’s motor and make sure that the blade’s RPM rating is lower than your motor’s specs. This will help ensure that you get optimal performance from both your blade and saw motor and will help avoid any potential damage.

Conclusion

This comprehensive guide should have given you a good idea of the key features to look for in a thin kerf table saw blade. The right blade can make a big difference to your craft, so it’s worth taking the time to find the perfect one.

Consider the type of projects and materials you plan to use most often, what weight of blade is most suitable, and whether a saw-specific version will provide better results than a generic model. Lastly, make sure to choose one that is sharp enough and suits your make and model of table saw.

By considering all these points carefully, it’ll be easier to make an informed decision on what is best for your needs and budget.

FAQ’S

What is the thinnest KERF saw blade?

The thinnest KERF saw blade is typically around 0.09 inches or 2.3mm.

What is the best blade to use on a table saw?

The best blade to use on a table saw depends on the specific task, but a general purpose or combination blade is a popular choice.

What is the best tooth count for table saw?

The best tooth count for a table saw depends on the task, but a 40-60 tooth count is commonly used for general purpose cuts and a 80-100 tooth count is best for finer cuts.

What is a 40 tooth saw blade used for?

A 40 tooth saw blade is commonly used for general purpose cuts in wood and other soft materials.

What is the best table saw blade for cutting plywood?

The best table saw blade for cutting plywood is typically a cross-cutting blade with 40-60 teeth.

What is the difference between Freud and Diablo blades?

Freud and Diablo blades both offer high-quality blades, but the specific product lines and materials used can vary.

Should riving knife be thinner than blade?

The riving knife should be the same thickness as the saw blade to ensure proper operation.

What is the thinnest cutting blade?

The thinnest cutting blade can vary depending on the specific application, but some blades can be as thin as 0.03 inches or 0.76mm.

Why are Japanese saw better?

Japanese saws are considered better due to their precision, craftsmanship, and teeth geometry, which allows for smoother cuts.

What saw blade is best for bone?

A 24 tooth saw blade is typically the best for cutting bone as it provides a faster cut with minimal splintering.

Michael Lilli is the author and CEO of sawbladetown.com and Informative Website. With over 10 years of experience in the saw blade industry, Michael has become a leading expert in the field. He is dedicated to helping professionals and hobbyists alike find the perfect saw blade for their projects. Through his informative website and writing, Michael shares his knowledge and expertise on everything from saw blade anatomy to advanced techniques and safety precautions. His passion for saw blades and commitment to helping others has made him a trusted resource in the industry.