Are you looking for the perfect pole saw blade to do all your gardening tasks? In this article, you will gain essential knowledge about pole saw blades, so you can make an informed choice.

With this guide, you can provide your garden with the right cutting power to keep it beautiful.

Introduction

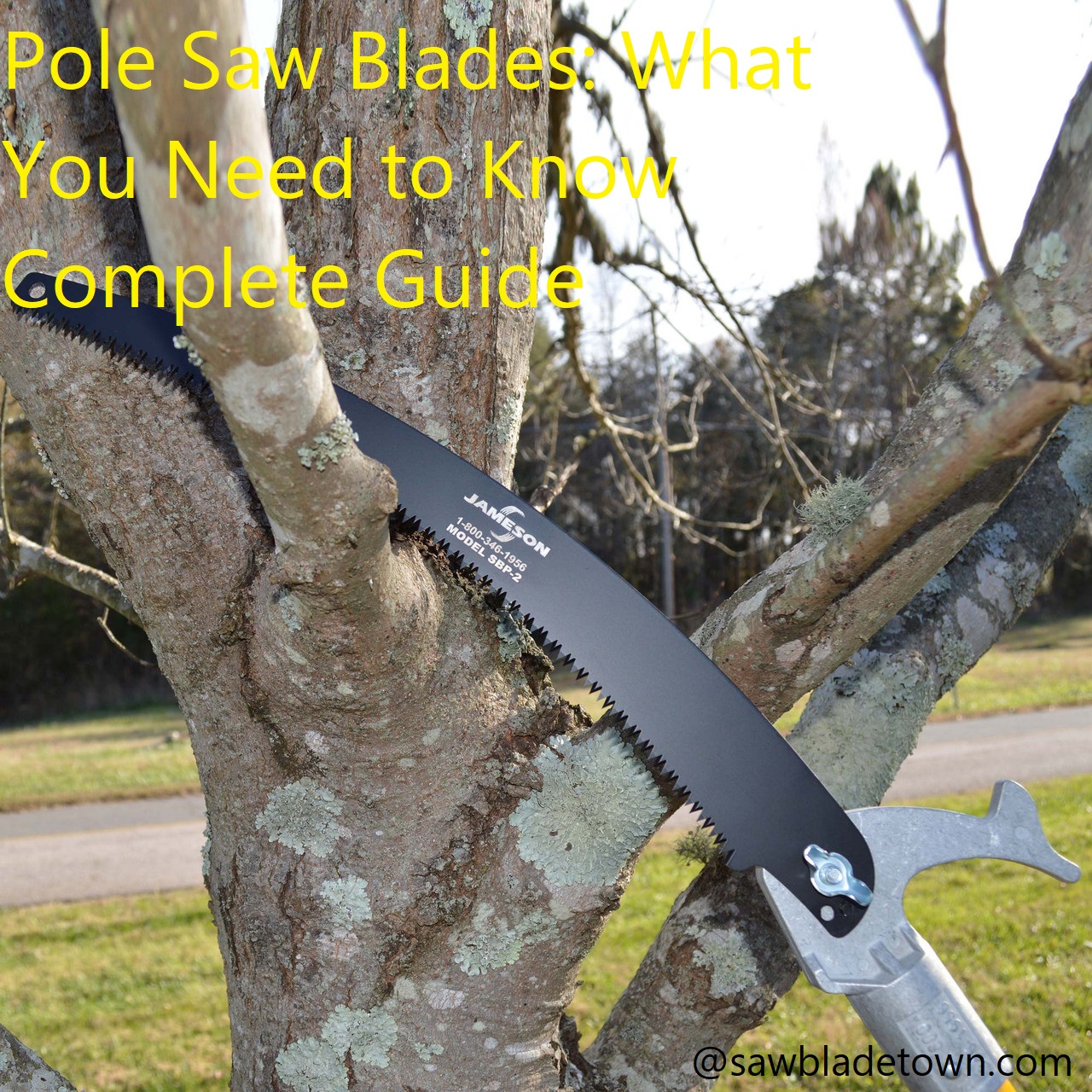

This guide will provide an in-depth overview of pole saws and the blades that are available for them. Pole saws are often used with a pruner that is attached to a long pole, allowing you to reach into heights where traditional handsaws and pruning devices cannot reach.

Pole saw blades come in all types of sizes, shapes, and materials. There are also pole saw blades for specific tasks like trimming tree branches or cutting metal pipes. This guide will explain the different types of pole saw blades available and what you need to know when choosing the right one for your job. It will also cover topics such as sharpening techniques and how to maintain your blade properly so that it lasts as long as possible.

Knowing exactly what to look for when selecting a new blade is essential if you want to get the most out of your purchase – so make sure you read through this complete guide!

Explanation of pole saw blades

Pole saw blades are important tools for cutting trees, pruning branches and sawing logs. They come in a variety of sizes and types, each suited to a particular machining task. A pole saw blade is usually made from high-carbon steel or alloyed steel designed specifically for strength and longevity. It can be used to cut through branches and logs of all sizes, and is an essential tool in any arborist’s arsenal. When selecting a pole saw blade, there are several factors to consider such as size, type, length, carbide teeth configuration and sharpening requirements to ensure that it is suitable for your particular job.

The size of a pole saw blade is determined by the distance between its two cutting edges, measured from the center point. Generally speaking, larger blades are better suited for larger cutting jobs, while smaller blades can handle more delicate work like trimming and shaping small branches or saplings. The length of the blade depends on the job being done; long blade will provide greater reach when you need to cut limbs further away from your body for safety reasons.

The most popular types of pole saw blades include straight back (toothed edge only), reverse/curved back (toothed edge on both sides) or combination blades (toothed edge on one side combined with an alternate specialty tooth pattern on the other). Different tooth configurations will yield different results when it comes to smoothness of cuts. For example straight back blades produce much smoother cuts than their combination counterparts. Lastly sharpening requirements should also be considered when selecting a pole saw blade – some require frequent sharpening while others have more durable cutting edges that can withstand multiple uses without requiring additional maintenance work.

Importance of having the right pole saw blade

When selecting a pole saw blade it is important to consider the type of material you will be cutting. Generally, more expensive blades are designed for lighter use and better performance, while cheaper blades are designed for tougher tasks in tougher conditions. For example, a softer metal saw blade can cause burrs if used to cut concrete or brick but would be fine for cutting wood.

The thickness of the metal used in the pole saw blade is also something to consider when choosing the right one. Blades constructed using thicker metal will generally last longer and endure more wear and tear than those made with thinner metal. This can offer an additional level of safety because thicker blades are less likely to suddenly fail when put under strain or pressure while cutting material.

The type of teeth used on the pole saw blade also plays an important role in determining how well it works and how long it lasts before needing replacement. Generally speaking, blades with larger teeth tend to make smoother cuts than those with shorter teeth, but they become dull faster due to their size. Smaller teeth offer greater durability, however they may produce a rougher cutting surface on materials that aren’t as dense or brittle such as wood.

Finally, the number of teeth found on each pole saw blade should be taken into consideration. For example, a 5-6 tpi (teeth per inch) pole saw blade may produce slower cuts but will last longer before becoming dulled from repeated use than a 12-14 tpi model that can cut faster but must be sharpened more frequently between uses due to its higher tooth count.

Materials Used in Pole Saw Blades

When considering Pole Saw Blades, it’s important to understand the materials that are used in their construction. It’s necessary to understand their properties and which type is best for your cutting job. It’s easy for manufacturers to use substandard materials in the saw blades in order to keep costs down and increase profits.

The most common materials used in the manufacturing of Pole Saw Blades are carbon steel, high speed steel, bimetal and stainless steel. Carbon Steel is a cheap material that can be hardened with heat treatment processes offering a good level of durability. High Speed Steel is an alloy steel containing tungsten, molybdenum, chromium and vanadium which increases its hardness and cutting ability as well as its ability to retain an edge during heavy usage applications. Bimetal is made up of two different metals with either 10% or 20% cobalt added – this provides increased wear resistance along with greater edge-holding qualities over the two standard steels outlined above. Finally, Stainless Steel has a higher rust resistance than any other material and it is often used because of its superior quality without sacrificing performance or cost efficiency.

Steel Blades

Steel saw blades are a popular choice for pole saws, as they are widely available, sharp and durable. Steel blades also come in various sizes to meet the needs of different types of users.

The two most common types of steel blades are carbon steel and high-speed steel. Carbon steel is a more economical choice for pole saw users, however it won’t last as long as the higher grade high-speed steel blades, which have the ability to stay sharp longer due to their increased hardness and wear resistance properties.

Steel blades should be regularly sharpened in order to maintain their cutting performance, although they do tend to be more forgiving than other types of saw blades when it comes to minor bumps or scratches on the cutting surface.

Carbon Blades

Carbon blades are becoming the preferred choice for many pole saws because they are lightweight, require less maintenance and are more resistant to corrosion. In addition, they offer considerable flexibility and durability while also providing maximum efficiency when cutting hardwoods. But there is a downside to using carbon blades – they can become brittle over time because of their tendency to bend or wear out quickly. Furthermore, these blades can be susceptible to breaking and should not be used for extended periods of time or in cutting large branches.

It is important to check the manufacturer’s guidelines on sharpening frequency as carbon blades must be regularly sharpened, depending on how often you use them. Without proper maintenance, the blade can eventually lose its edge, so it’s best to sharpen it every 2-3 months. Moreover, due to their thinner construction, carbon blades may tend to flex or fold instead of giving a clean cut. Finally, before purchasing a pole saw with a carbon blade make sure you choose one that has been tested for quality and that comes with a warranty.

Diamond Blades

Diamond blades are a popular choice when cutting hard materials and are commonly used for projects such as tile and ceramic cutting, granite countertop cutting, concrete project cutting, glass cutting, reinforced concrete (forebore) blade cutting, flooring applications and mining.

Diamond blades consist of a steel core with diamond particles welded to the perimeter. This type of blade is known for its superior hardness and abrasion resistance. The diamond particles are bonded to the steel core in various ways depending on the manufacturer and quality of the blade. Lower quality blades may only have an abrasive coating on one side of each tooth which will reduce its performance in certain applications. Higher quality blades will have full depth diamonds with superior heat resistance that can last longer when used for demanding tasks such as drilling through heavily reinforced concrete or curing dense material like asphalt.

Diamond blades are available in wet use and dry use versions with differing electrical specifications depending on the type of saw they will be used on.

Maintenance and Care of Pole Saw Blades

It is important to take proper care of your pole saw blades to ensure that they are able to function properly. There are several tips you can use for maintenance and care that will help keep your blades in good condition and make them last longer.

First, it’s important to store your pole saw blades in a cool, dry location, away from direct sunlight. Sunlight can cause the material on the blades to discolor or weaken over time. In addition, be sure to keep any moving parts such as screws and nuts properly lubricated with oil to prevent rust from building up and causing problems.

Second, it’s important to regularly clean the blades using non-abrasive cleaning materials such as a soft cloth or brush. This will help ensure that debris does not build up on the blade and lead to rusting or corrosion of the material. Regular cleaning with specialized polesaw cleaner can also help remove any built-up contaminants such as sap and resin that may have lodged themselves onto the blade surface.

Third, check for any dents or damage on a regular basis by running your hand along the blade’s edge. Any dents should be taken care of immediately by filing down the edges or replacing damaged parts so they do not interfere with the cutting performance of your pole saw blade. Finally, sharpen pole saw blades periodically when necessary in order to keep them in top condition for optimal performance. Depending on its type and how frequently you use it, sharpening could occur anywhere between every few weeks or once a year – always read manufacturer instructions before sharpening!

Cleaning the blades

A pole saw can help you trim branches and limbs away from your lawn in a safe and efficient manner. However, it’s important to keep the blades of your pole saw well-maintained over time to ensure they stay sharp, effective and long-lasting. Cleaning the blades of your pole saw regularly will help remove harmful debris, such as sap and other debris that can dull the blade edges over time. Here are a few tips for regular cleaning:

- Unplug the power supply cord from your pole saw before starting any maintenance work on the tool’s blades.

- Wipe down the blade(s) with a cloth or soft brush using warm, soapy water to remove any dirt or debris that has built up on its surface/edges. For tougher build-ups of sap or other organic matter, use a mild solvent such as rubbing alcohol to loosen it away from the surface of each blade’s teeth.

- After wiping down the pole saw’s blades, rinse them off with warm water and make sure they are completely dry before plugging back in and use the tool once again.

- You may also want to sharpen your pole saw blades once every few months for best performance results – either using a file or an electric sharpener depending on each individual model recommendation outlined by its manufacturer’s instructions.

Sharpening the blades

Sharpening pole saw blades is necessary to maintain the desired cutting edge and prolong the life of your pole saw. Generally, two methods are available for sharpening: electric and manual.

Electric sharpening offers a fast and effective way to get a consistent edge, but you may need professional support because of the skill involved and safety issues. Alternatively, manual sharpening requires filing techniques with a small file or round saw file — depending on your objective. While manual sharpening takes more skill, effort and patience, it’s less expensive than an electric service and can be done from home.

If you’re starting from scratch with both methods —making sure that the angle is correct will be the most important factor in getting an effective cutting edge. It’s important to use a good quality blade that won’t need as much maintenance over time; generally, it will have large chipbreaker slots on its surface which help disperse sawdusti as it marches along its path. Regular inspection of your pole chainsaw blades will help you identify any potential problems before they become more serious such as dulling or wear in the teeth shape. Properly maintained blades will enhance performance while ensuring safety measures are taken care of to protect yourself and those around you when operating your pole saw blade tool.

Safety Considerations When Using Pole Saw Blades

When using any type of saw, regardless of the size or type, it is important to ensure that proper safety precautions are taken. The following recommendations are designed to help you use the pole saw blade safely and securely.

- Wear protective equipment such as gloves, goggles, and a face shield to protect your skin and eyes from any flying debris.

- Make sure that the area you will be working in is clear of people and objects prior to starting.

- If a ladder is needed for safe operation, be sure to double check that it is stable before reaching for saw blades.

- Unplug the saw when making adjustments or changing out blades on the pole saws. Also unplug it when not in use for an extended period of time.

- Test the blade before use by gently touching it with one finger; if it feels sharp or rough, replace it immediately. Replace dull or worn out blades for maximum efficiency and safety purposes.

- Always keep your body properly aligned when reaching up with the pole saw blade in an overhead position; this will help you maintain balance while working with one arm overhead.

- Maintain proper footing on solid ground when using a ladder instead of an unstable surface.

- Check around your work area often during operation to ensure children or pets have not entered without permission.

Wearing safety gear

It is important to wear the necessary safety gear when using a pole saw. Wear hearing protection and a face shield or safety glasses, along with some heavy-duty work gloves whenever operating the pole saw.

There is also the potential for debris to fly up into the air, so if possible, opt for full head coverage. This can include wearing a protective hard hat as an extra precaution. Additionally, closed-toe shoes are recommended to protect your feet against any flying pieces of wood or metal while working.

Proper handling of the pole saw

To ensure the longevity of your pole saw blade, it is extremely important that you handle and care for it properly. The first step to ensure this is to make sure you have the right protective gear. This includes gloves, eyewear, and steel-toed boots. Additionally, you should always use a harness when working from a ladder or extended pole saw extension.

The next step is to always inspect your pole saw before using it. Look for any signs of wear and tear or fatigue in the blade or handle and be sure to replace any worn/broken parts with new ones. You should also sharpen the blades occasionally or after periods when usage has been high in order to keep them sharp and efficient longevity of use. When performing maintenance on your pole saw such as cleaning, oiling, sharpening or replacing parts it is important to never overstress any components by using excessive force or torque as this can cause potentially irreversible damage to the blade or handle.

It is also very important that you always disconnect the power source when performing these types of maintenance tasks.

Finally if you notice any signs of wear on your blades cease its usage until proper maintenance can be performed as continuing use with damaged blades can cause further deterioration leading ultimately to damage beyond repair and potential safety issues for yourself or others near you during operation.

Conclusion

In conclusion, pole saw blades are a great tool to have on hand for pruning and trimming trees and other tall plants, but it is important to understand the different types available before purchasing a new blade.

By being knowledgeable about the different materials, styles, lengths, shapes and sizes that are available in the market, you can make an informed decision when buying one.

With proper storage, maintenance and use of your pole saw blade you can enjoy using your pole saw for many years to come

FAQ’s

What to look for when buying a pole saw?

- Length and reach of the pole saw

- Blade quality and size

- Power source (electric, battery, or gas)

- Weight and portability

- Safety features

- Price and brand reputation

What do you use different saw blades for?

Different saw blades are used for cutting different materials such as wood, metal, and plastic. The teeth of the blade can also vary in size, shape, and spacing depending on the type of cut you need to make.

What are the classification of saw blades?

Saw blades can be classified based on their size, shape, tooth pattern, and the type of material they are designed to cut. Common types of saw blades include circular saw blades, reciprocating saw blades, band saw blades, and jigsaw blades.

How do you use a pole saw safely?

- Wear protective gear such as eye and ear protection, gloves, and sturdy shoes

- Keep the blade away from your body and others

- Avoid cutting above your shoulder height

- Ensure the pole saw is properly secured and stable before use

- Follow manufacturer instructions and warnings

How many volts are good for pole saw?

The voltage for a pole saw will depend on the power source (electric, battery, or gas) and the intended use. Generally, a battery-powered pole saw with 20-40 volts is suitable for light to medium-duty cutting tasks.

What is the best pole saw on the market?

The best pole saw on the market will depend on your needs and budget. Some top-rated options include the Sun Joe SWJ800E Electric Pole Saw, Greenworks PRO 80V Cordless Pole Saw, and the gas-powered Echo PPT-2620H.

What are the 4 types of saw blades?

The four types of saw blades are:

- Rip blades

- Crosscut blades

- Combination blades

- Dado blades

What are the four types of blades?

It’s unclear what you are referring to with “four types of blades”. If you are referring to saw blades, please see the previous answer.

What is the strongest type of saw blade?

The strength of a saw blade will depend on the material it is made of and its intended use. Carbide-tipped blades are known for their durability and are often used for cutting harder materials such as metal and masonry.

Which is the most common saw blades?

Circular saw blades are one of the most common types of saw blades and are used for a variety of cutting tasks including ripping and crosscutting wood, as well as cutting plastic and metal.

See Also:

- Best saw blade

- Best ripping blade for table saw

- Best rip saw blade

- Best pruning blade for reciprocating saw

- Best pole saw blade