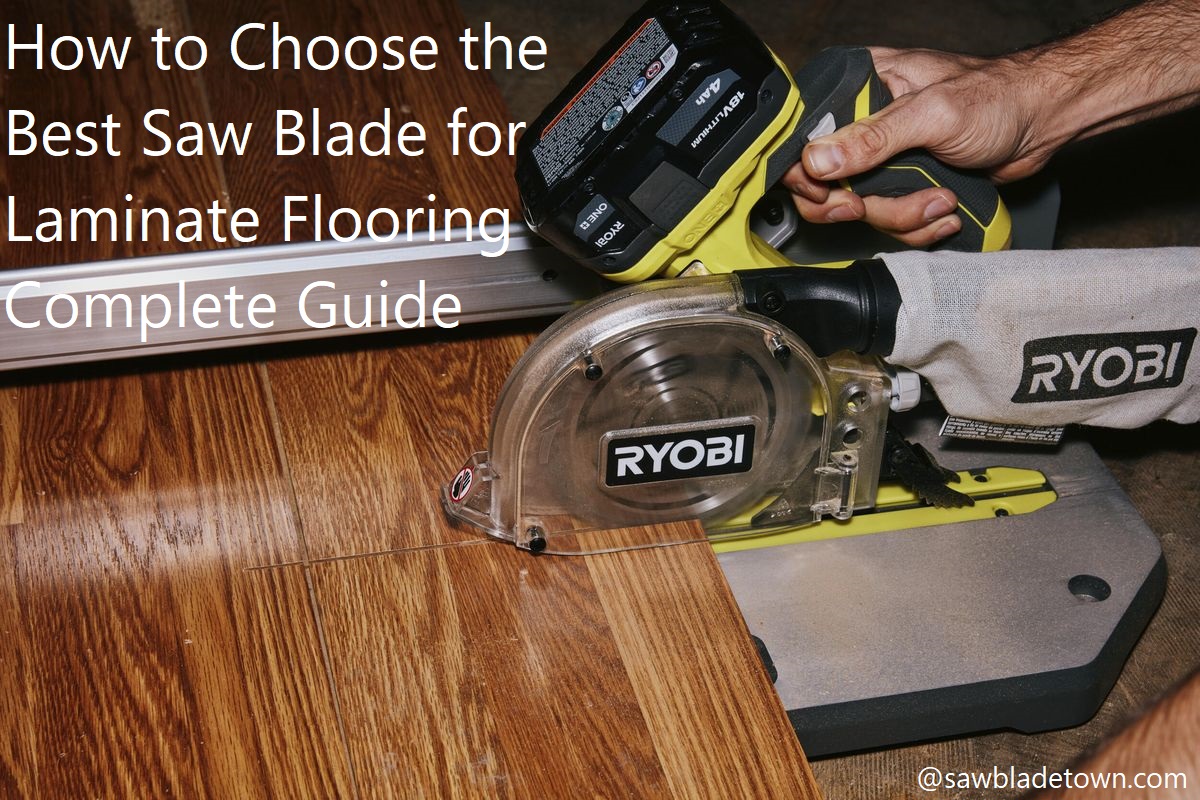

Are you confused about which saw blade to use for installing laminate flooring? Don’t worry, you’re not alone. Choosing the right saw blade can be a daunting task if you don’t know the details.

This guide will provide you with all the information you need to make an informed decision and select the best saw blade for your project.

Having the right saw blade for your laminate flooring is essential for getting good results. Whether you’re cutting a straight line, making a curve, or trimming off a small portion of the floor, using the wrong saw blade can quickly lead to mistakes that waste time and material. With so many types of saw blades available it can be difficult to know where to start.

This guide will explain the key factors to consider when selecting a saw blade for laminate flooring and provide recommendations on how to choose the right tool for your project. It will discuss differences between saw types such as circular, miter and jigsaw blades. Lastly, troubleshooting tips and best practices will be presented so that readers can get the most out of their saw blades when tackling their next task.

Briefly introduce the topic of choosing the best saw blade for laminate flooring

Choosing the right saw blade for your laminate flooring project can make all the difference in getting a professional finish. Before selecting a saw blade, it is important to consider factors including the quality of cut, blade life and accuracy. The type of saw being used must also be taken into account to guarantee compatibility with the required specialized cutting tool.

In this guide, we will outline what tools and blades are available, as well as how to select a suitable width and tooth configuration for any type of project.

State the importance of selecting the right saw blade for the job

Choosing the right saw blade for any job is an important step in ensuring a successful project. This is especially true for laminate flooring, as the wrong blade can cause unnecessary reduction in material quality and even accidental injury. By understanding what different blades do, you can make an educated choice when selecting your saw blade, increasing the chances of a safe and successful project.

When choosing a saw blade for laminate flooring, it is important to consider its tooth set, face size, rake angle, hook angle and gullet depth. The tooth set refers to how teeth are arranged or “set” on the face of a blade and affects how smoothly or aggressively cuts made by that blade will look; faces with higher sets (such as rakers) provide smoother cuts while those with lower sets cause more aggressive ones. The size of a facing determines the width of material that can be cut without crowding; larger sized faces allow for wider cuts than smaller blades. Rake angle describes how steeply teeth come to their point off the body of the blade; steeper angles means more aggressive cutting action while shallower angles provide smoother cuts when operated at high speeds. Hook angles refer to how steeply teeth on circular saw blades enter material being cut; steeper angles allow for more rapid cutting but poorer finish quality whereas lower hook angles facilitate slower movement with better finished quality. Finally, gullet depth determines chip clearance from larger pieces when cutting through dense material such as engineered flooring; greater depth increases chip removal speed but requires higher RPMs to remain effective during use.

By understanding these parameters and their relationship with different blades–as well as one’s project-specific needs–one can identify which type(s) of saw blades are most suitable for their own unique laminate floor installation job thereby increasing safety and efficiency during operation.

Provide an overview of what the guide will cover

This guide provides an overview of the considerations for selecting the best saw blade for cutting laminate flooring. We will discuss the different types of blades and their strengths and weaknesses, how to determine the size of blade needed for a particular job, and how to select a blade that has been designed specifically for this kind of work.

Additionally, we will provide an overview of essential safety practices when using power saws on laminate flooring. By understanding these key features, you can make sure your next project is done safely and efficiently.

Factors to Consider when Choosing a Saw Blade for Laminate Flooring

In order to make sure you get the most out of your saw blade and achieve the cleanest cuts possible, there are a few factors that you should consider when choosing one. The saw blade’s tooth design and size, material, and rotation speed are among the aspects you should take into account before making your decision.

Tooth Design and Size The tooth design of a saw blade for laminate flooring will influence its cutting speed and quality. Generally, blades with small teeth provide cleaner cuts in hardwood or softwood due to having smaller gullets in-between teeth. However, if you’re looking for a blade that can cut through laminated boards with ease then it’s best to opt for a saw blade with larger teeth as these have larger gullets that make it easier to cut through dense materials. Additionally, you should also consider the size of the tungsten carbide tips on each tooth as these will impact the performance of your saw blade and how long it will last.

Material The material of your saw blade can also affect its performance on different materials such as wood or plastic laminates. Hardened steel is typically considered one of the better materials when it comes to making highly durable blades suitable for difficult tasks while carbon steel saw blades offer excellent value given their affordability. As laminate flooring is generally denser than other types of wood panels, it is best to use a tool specifically designed for cutting through laminate flooring since this will often perform better than using a general-use tool like an ordinary circular saw blade or miter saw blade.

Rotation Speed It’s important not to forget about rotation speed when choosing a saw fan specifically designed for laminate flooring installation projects or similar detailed work-pieces such as trim carpentry projects around doorframes or windowsill installments . Variable rotation speed settings allow users to adjust their blades according to what type task is being completed from light duty projects all the way up to more complex projects requiring high RPM rotations speeds such as tile cutting jobs or angled cuts for crown mouldings install tasks.

Type of saw blade

When it comes to choosing the right type of saw blade for your laminate flooring project, there are a few factors that you need to consider. Based on your needs, the saw blade may either be carbide-tipped, steel-backed, or hi-tech diamond blades.

Carbide-tipped saw blades are one of the most common types of blades used in woodworking and woodcutting applications. They feature tiny pieces of tungsten carbide as cutting tips that maintain their sharpness even after prolonged use. These blades are ideal if you are planning to cut through much denser material such as laminated particle boards or compressed hardwoods that regular steel saws could not handle.

Steel-backed blades are also a great choice for laminate flooring projects because they offer good durability and offer an excellent balance between price and performance. These blades feature very thick and tough steel backing plates at the back which is why they can manage more weight and won’t easily break even when put under pressure for thicker materials.

Hi-tech diamond blades are also another option you have when it comes to laminate flooring cutting tools. Diamonds act as a highly abrasion resistant cutting surface which makes them perfect for tough materials like laminates with minimal weariness while providing a smooth clean cut. They tend to be more expensive than other blade types but they offer great value if you need quick and accurate cuts with minimal effort due to their known superior staying power over time thanks to their hardness and durability in comparison with other similar machines out there.

Tooth count

When choosing the best saw blade for laminate flooring, one of the most important considerations is tooth count. Generally speaking, higher tooth count blades have finer teeth and produce a smoother, more accurate cut in softer materials, like laminates. Lower tooth count blades work better for hard materials, including thicker laminates and floorboards with plywood backings. The most common ranges of tooth count are from 10 to 120 teeth. As a general rule of thumb, laminated wood flooring needs around 60 to 80 teeth per inch (TPI) for the best finish.

In addition to their TPI range, saw blades may be available with various hook angles (the angle of the blade’s teeth). The hook angle can impact how easily a blade cuts through material and how smoothly the cut surface appears after use. Generally speaking, saw blades come with hook angles between zero and 20 degrees; it is wise to choose blades with hook angles around 10 degrees when cutting laminate flooring.

For additional smoothness on your cuts you may consider an alternate top bevel (ATB) saw blade that has specially-designed curved teeth provides a cleaner cut and smoother edge on laminates than other types of blades do; they are ideal for curved or arched cuts as well as straight cuts. ATB saw blades are also good choices when working with thin sheet materials like veneers or plywood since their tip geometry requires less pressure to make clean cuts compared to standard flat-top blades.

Diameter of the blade

The diameter of the saw blade used for cutting laminate flooring is an important factor which will determine the quality of your cut. Generally, the larger the diameter of the blade, the more exact and smoother your cut will be. As a general guide, blades should be at least 12 inches in diameter for optimal cutting results.

Large wheels also create less vibration and noise during operation. If you don’t have a wildly powerful motor or need to make extra fine cuts, then 10 inches is suitable as well. Alternatively, a 14-inch saw blade gives you more agility over small corners while cutting floor boards to shape; however it adds some more weight and can add further strain on your motor.

Blade material

The material a saw blade is made of dictates how well it performs in different types of materials and how long it will last. Saw blades for laminate flooring should be made from carbide-tipped steel, which is one of the hardest materials used in saw blades and provides excellent durability.

Carbon steel blades are another type of blade material which is generally more economical, though it doesn’t offer the same level durability as carbide-tipped blades. Depending on the type and manufacturer, carbon steel blades can be used to cut laminate flooring, though they may not last as long.

Kerf size

The kerf size of the saw blade is one of the most important criteria when it comes to selecting the right saw blade for your laminate flooring project. The kerf is essentially the width or depth of the cut that will be made with the saw blade. In relation to laminate flooring, a smaller kerf size saw blade is typically best as it creates a clean and precise cut with minimal debris and splintering.

When shopping for a saw blade, you need to pay close attention to both the tooth and pitch (TPI) as well as the kerf size of the selected model. A TPI measurement indicates how many teeth are found on each inch of a saw blade, while a larger pitch creates more powerful but rougher cuts. Generally speaking, thinner and sharper blades tend to produce cleaner and more precise cuts than thicker models with fewer teeth per inch (TPI).

To ensure that you get a high-quality finish with minimal waste on your laminate flooring project, choose a saw that has an optimal kerf size in relation to its TPI measurements. For example, if you’re using thinner blades like 24 or 30 TPI models, then look for blades that have a smaller kerf size such as 7/32-inch or 5/32-inch. However, if you’re dealing with thicker laminate materials then consider using larger blades with 9/32-inch or 11/32-inch kers sizes instead. Ultimately, keep in mind that shallow cuts create cleaner results when cutting laminate flooring — so always opt for smaller kers sizes where possible!

Arbor size

When selecting a saw blade for laminate flooring, people should first consider the arbor size of their saw. The arbor is the hole in the middle of the saw blade where it attaches to the saw spindle. This can vary between ¼ inch and 1 inch. Just make sure that the blade you select matches your saw’s arbor size. If you’re not sure of your saw’s arbor size, consult your owner’s manual or measure it yourself.

Additionally, look at how many blades are on a particular model of saw blade to determine its suitability for laminate flooring projects. Generally, more blades offer smoother cuts since they make more contact with the material when cutting. Some blades have as few as two teeth, while others offer 10 or more teeth for a finer cut. A minimum of five to six teeth may be necessary for cutting through laminate flooring without leaving too much residue behind or creating frayed edges on pieces.

Your choice in blade also depends on whether you need a full-sized circular saw ideal for larger projects or smaller jigsaws for smaller pieces and corner cuts.

Conclusion

In conclusion, choosing the best saw blade for laminate flooring is a process that requires thought and consideration. The type of saw you use, as well as the make and material of the blade, can all have a major impact on the quality of your cut. It’s important to take into account factors such as cost, quality and compatibility before selecting your saw blade. With proper research, you can find the perfect blade for your laminate flooring project that will provide precise and precise results every time.

FAQ’s

What size blade do you use to cut laminate flooring?

The recommended size blade to cut laminate flooring is 10 inches.

What is the best TPI for cutting laminate flooring?

The best TPI (teeth per inch) for cutting laminate flooring is between 80 and 100.

Does laminate flooring ruin saw blades?

Yes, laminate flooring can wear down saw blades faster than other materials, so it is recommended to use a blade specifically designed for laminate flooring.

How many teeth does a laminate floor saw blade have?

A laminate floor saw blade typically has between 60 and 100 teeth.

What blades are best for cutting compact laminate?

Carbide-tipped blades with a high tooth count are best for cutting compact laminate.

What tools do I need to lay a laminate floor?

Tools needed to lay a laminate floor include a saw, spacers, tapping block, pull bar, measuring tape, utility knife, and a rubber mallet.

How do you measure angle cuts for laminate flooring?

To measure angle cuts for laminate flooring, use a bevel gauge or protractor to determine the angle and then transfer that angle to the laminate plank with a pencil.

Is 12mm laminate better than 10mm?

12mm laminate is thicker and more durable than 10mm laminate, but the choice ultimately depends on personal preference and the specific needs of the space.

How do I choose laminate thickness?

Choose laminate thickness based on the amount of foot traffic the area will receive, with thicker laminates being more durable for high traffic areas.

What is the abrasion rating for laminate flooring?

The abrasion rating for laminate flooring is measured on the AC (abrasion class) scale, with higher AC ratings indicating greater durability.

See Also:

- Best concrete saw blade

- Best combination table saw blade

- Best circular saw blade for plywood

- Best circular saw blade for cutting doors

- Best circular saw blade