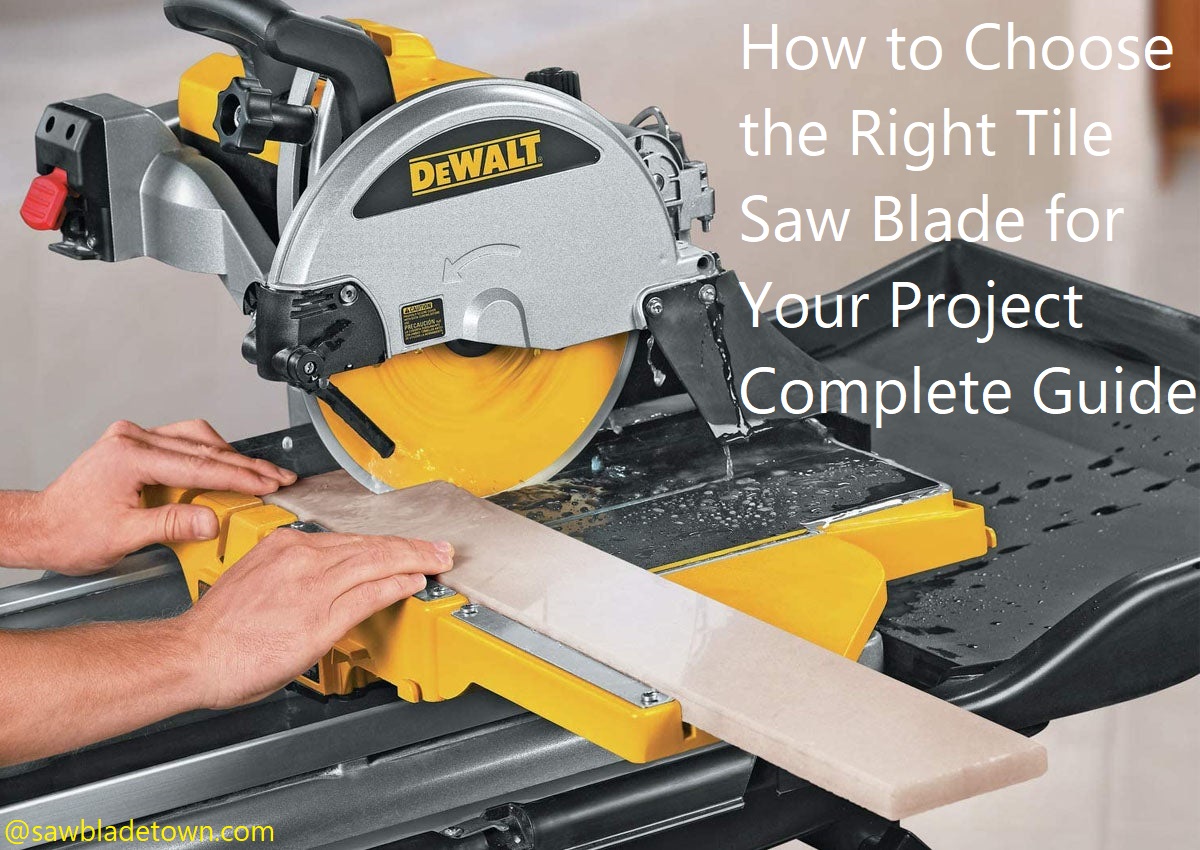

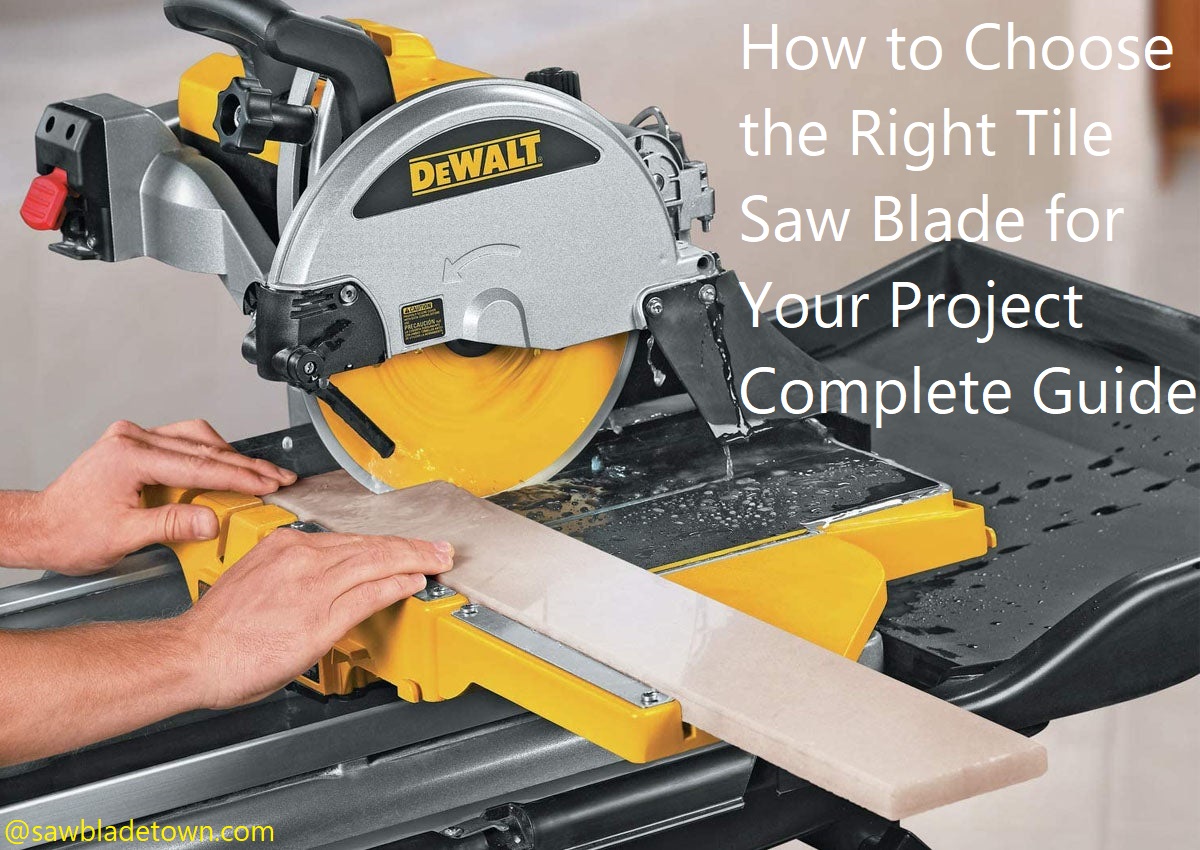

You’re probably looking for the right saw blade to get your project completed right? Choosing the right saw blade often takes time, energy, and experience. That’s why this article is here to help you make an informed decision, so you can be sure to choose a saw blade that will deliver top-notch results.

Introduction

Tile saw blades come in a variety of sizes, types, and configurations to accommodate the many different applications they are used for. It can be difficult to determine which type is the right one for your project. This guide will help you make an informed decision so that you can select the best tile saw blade for your specific needs.

Tile saw blades are essential tools when it comes to repairing or constructing ceramic tile projects. The right blade can make all the difference in both precision and accuracy. It also greatly affects the overall cost of the project, as it is often one of the more expensive components required for tile work. Therefore, it is important to understand some basic information about tile saw blades before making a purchase.

Types of Tile Saw Blades

Tile saw blades come in a variety of types, each with their own advantages and disadvantages. In order to determine the best type for your project, you must first consider what kind of cut you will be making. There are four main types of tile saw blades: steel-tipped diamond blades, continuous rim diamond blades, turbo rim diamond blades and wet tile saws. Here are some quick details on each type:

Steel-Tipped Diamond Blades – These saw blades are ideal for most ceramic and porcelain tiles. They feature a steel core that is surrounded by a thin layer of diamond particles, which gives them their cutting power. Steel-tipped diamond blades offer excellent accuracy and durability and can handle cuts up to 1/2 inch thick.

Continuous Rim Diamond Blades – This type of blade offers continuous smooth cuts without chipping or cracking the material being cut. The blade should be used at slower speeds in order to avoid damaging the material being cut. Continuous rim diamond blades are ideal for natural stones such as marble and granite.

Turbo Rim Diamond Blades – These saw blades feature an innovative design that creates a high RPM cutting speed which allows for fast cuts through even the hardest materials. They make fewer chips than other types which helps reduce long-term damage to expensive tiles as well as helping to keep your job time down significantly.

Wet Tile Saws – Wet tile saws are designed specifically for cutting ceramic tile, porcelain tile, natural stone and similar materials such as glass mosaics or engineered stone products like quartz or Corian countertops. This type of blade utilizes both water and electric power in order to accurately cut material at various speeds depending on your needs.

Continuous Rim Blade

A continuous rim blade is designed for a smooth, clean cut and is typically used on tile with a softer material, like ceramics and terracotta. If you are dealing with some of the tougher tile materials like porcelain, you should use a different type of saw blade.

Continuous rim blades come in various sizes and can either be wet-cutting or dry-cutting. When deciding which size to purchase, it’s best to reference the manufacturer’s instructions for your tile saw brand, as well as any additional instructions from the particular blade manufacturer. This will ensure that you are using the correct type of blade for your project.

Generally speaking, using a larger diameter saw blade will provide for a smoother cut whereas smaller diameters tend to create more dust due to higher RPM speeds needed with smaller blades.

Segmented Rim Blade

Segmented rim blades are designed with multiple “segments” of diamond-coated cutting teeth arranged around the edge of the blade that allow for extremely fast, accurate, and consistent cutting. This type of saw blade is usually composed of metal body with many tiny diamond chips set in a wet or dry metal bond. It performs well on cement board, fiberglass, PVC plastic, and other materials that require more precision and heat dissipation.

Segmented rim blades are most commonly found on electric tile saws and handheld wet tile saws because they produce less friction when used on ceramic and porcelain tiles. Furthermore, segmented rim saw blades provide improved cooling capability due to their unique design which produces fewer sparks at lower RPMs and allows for smoother operations. They come in various sizes such as 4” – 14” in diameter which makes them ideal for any size job or project.

Blade Diameter

Choosing the right diameter of tile saw blade largely depends on the size of the material you are cutting. In general, larger blades cut faster but can be difficult to maneuver on smaller tiles; in contrast, smaller blades are easier to maneuver on small tiles but may need more passes to achieve optimal results. When choosing a blade, be sure to select a size that is slightly larger than your tile. To ensure you get the most effective and correctly sized blade for your project, consider consulting product specifications provided by the tile saw manufacturer.

When it comes to choosing a blade for your wet saw or angle grinder, note that different materials require different sizes of blades. For ceramic tiles, use a 4-inch or 5-inch diameter (10-12 cm) blade; for porcelain tiles, use an 8-10-inch (20 – 25 cm )diameter blade; and finally for marble or other stone tiles, consider using an 11-14 inch (28 – 36 cm) diameter blade. Finally, keep in mind that larger blades will often last longer than their smaller counterparts due to their increased sturdiness and resilience against momentum losses as they cut through materials with greater ease.

Explanation of blade diameter

When purchasing a tile saw blade, one of the first considerations is the blade diameter. The blade diameter of a tile saw typically ranges between 4” to 10.” Generally, larger blades are required for large tiles and walls while smaller blades are suitable for small jobs like trim work or precision cutting.

One should bear in mind that larger blades may require more power; therefore it is important to consider the power of your tile saw before you choose your blade size. Additionally, when choosing a tile saw blade, you should make sure that they fit your particular model of tile saw as model sizes can vary.

Factors to consider when choosing blade diameter

When choosing a tile saw blade, there are several factors to consider, such as size and construction. One of the most important factors to consider is the diameter of the blade. Depending on the material and type of tiles that you will be cutting, you should choose a tile saw blade with the appropriate diameter. Generally speaking, larger blades are better suited for thicker and harder materials while smaller blades offer better precision and control for finer tile work.

In general, three common sizes of diamond blades for cutting tiles are available:

-4-inch blades: This size is best used for thin ceramic and porcelain tiles, glass mosaics, and other intricate designs where accuracy is critical. They produce less heat when in operation which significantly reduces potential damage to delicate finishes.

-5-inch blades: This size works well with more substantial material like quarry stone or pavers that need straight cuts without chips. This size is usually offered with both turbo or continuous rim styles depending on what you’re cutting through.

-7-inch blades: These large diamond saw blades can tackle thick stone tiles or engineered stone such as marble more easily than smaller versions due to their higher power output and cutting speed.

Blade Material

There are a variety of materials used in the manufacture of tile saw blades. Each material has advantages, and depending on your project you may need a particular type of blade. The most common types are carbide-tipped blades and diamond blades.

Carbide-tipped blades have an alloy steel body with carbide tips brazed to the outside face of each segment. The tips are applied with a technique that ensures they stay firmly attached and protect against breakage. This type of blade will give you an excellent cut, but will wear out faster than diamond blades due to the softer metal and short cutting life.

Diamond blades are made with diamonds embedded into metal matrixes which makes them incredibly durable and long lasting. They offer superior cutting performance compared to traditional abrasive discs and can handle cuts in hard or soft materials such as porcelain, ceramic, clay tiles as well as masonry products like brick, stone or even concrete blocks without experiencing significant wear or tear. Additionally, these saws tend to be quieter than some other saws due to their construction making them a great choice for larger projects where noise is not desired.

:max_bytes(150000):strip_icc()/cutting-tile-with-a-wet-saw-182459158-5882b46e3df78c2ccd51e099.jpg)

Diamond Blades

Diamond blades are the most popular type of tile saw blade. They cut cleanly and quickly, with minimal chipping and have an incredibly long life expectancy. Diamond blades are also offered in a variety of sizes, ranging from 4″ to 16″, for use on both small and large jobs. Whether your project is a remodeling job, a kitchen remodel, or something else entirely, you can find a diamond tile saw blade that fits your needs perfectly.

When selecting the perfect diamond blade for your project, the best choice is to consider the type of material you’ll be cutting, as diamond blades are available with different diamonds sizes (based on grit level). A larger grit will produce harder cuts at slower speeds while smaller grits can produce softer cuts at higher speeds. Additionally, when cutting faster-grinding materials such as marble or granite, it’s important to use a higher quality blade containing bigger diamonds that can stand up to the harshness of these materials. In other words: if you’re often working with softer materials such as ceramic tile or porcelain mosaic sheets (which require less friction), a lower-quality blade containing smaller diamonds might suffice.

Carbide-Tipped Blades

Carbide-tipped blades are designed for hard tiles, such as masonry, porcelain and stone. They tend to last longer and deliver a better cut than the more economical steel tungsten carbide blades. Carbide-tipped blades have tiny pieces of tungsten metal and nickel brazing welded onto the tips of the individual segments. This combination of materials allows carbide-tipped blade to hold an edge longer than other types of tile saw blades, but they still will wear out over time, depending on what type and how hard the tile is that you are cutting.

When choosing a carbide-tipped blade, look for one with fewer teeth per inch (TPI). The fewer teeth necessary means that each tooth can be larger, allowing it to bear more load during cutting. When fewer teeth pass through material while making a cut it also minimizes chipping or breaking along the edge of cut pieces of tile. Additionally, because fewer teeth contact tile at any given time it keeps stress on each tooth lower as compared to other kinds of diamond blades. As a result, longer life can be expected from center core carbide-tipped saw blades even when cutting hard materials like porcelain and dense concrete pavers.

Wet or Dry Cutting

The primary question when selecting a tile saw blade is whether you need to cut dry or wet. Dry cutting is often used for ceramic and porcelain tiles because it produces low dust levels. The downside to dry cutting is that the blades wear quickly, and don’t last as long as wet-cutting blades.

Wet cutting is recommended for larger projects using extremely hard materials such as natural stone, or when a smooth cut surface is required, such as with glass tiles. The water cools the blade and helps to keep dust levels lower compared to dry cutting. Wet-cutting blades tend to be more durable and last longer than dry-cutting blades.

When purchasing a tile saw blade, check the manufacturer’s guidelines to ensure the correct type of saw blade for your specific project. In addition, bear in mind that different materials require different blade types: ultra hard tiles need diamond blades; marble needs turbo diamond blades; granite requires continuous rim diamond blades; ceramic/porcelain require segmented or continuous rim blades; glass requires continuous or polycrystalline diamond blade; and slate requires segmented diamond with steel core aperture design.

Explanation of wet and dry cutting

When it comes to choosing the right saw blade for your tile cutting project, wet and dry cutting capabilities should be considered.

If you plan to perform a wet cut through tile, it is important to use a saw blade specifically made for that purpose. Wet-cutting blades have a special bond and grit designed to withstand the contact with water. Dry-cutting blades, however, are made from special minerals that ensure they don’t become damaged when used in air or on dry surfaces.

Both types of blades can easily cut through ceramic and porcelain tiles, as well as other stone materials such as marble and limestone. Taking into account what type of cut you plan to perform should guide your decision when purchasing any tile saw blade.

Factors to consider when choosing wet or dry cutting

Choosing the right tile saw blade is important for ensuring a clean, precise cut in your tile project. There are two main types of saw blades – wet and dry cutting – which you should carefully consider when deciding on the right one for the job.

Wet cutting blades are typically used with a water pump to keep dust and debris from scattering when cutting. This also helps to cool down the saw blade so there is less heat build-up and chance of warping or cracking your tiles. Wet cut blades may take longer to cut than dry blades, but they will produce cleaner, more accurate cuts with less chipping on harder materials such as porcelain and ceramic tiles.

Alternatively, dry cutting blades may be the better option for certain projects due to their faster speed – ideal for small jobs or removing grout quickly during repairs. They are usually made from softer materials like diamond-coated steel which means they can handle more aggressive cuts but will wear out faster if used incorrectly. When using a dry cut blade it is important that you put a protective covering over your work area as it will create large amounts of dust while cutting, making a mess and potentially causing health risks if inhaled.

Both wet and dry cut tiles have their own advantages depending on what type of project you’re doing, so it’s important to choose the right one before starting your job!

Conclusion

Conclusion

In conclusion, there is no one-size-fits-all answer when it comes to selecting the right tile saw blade for your project. The type of material you are working with, how long you need the blade to perform optimally and your budget should all be taken into consideration when making your selection. Be sure to look into all of your available options carefully and choose the one that best fits your particular needs.

Ultimately, finding the right tile saw blade can be a tricky job—but there are plenty of great tools and products out there that can help make it easier. Taking the time to research features, specifications and reviews will help ensure that make an educated decision so you can get just what you need for a successful project.

FAQ’s

How do I choose a tile saw blade?

You should consider the type of tile you are cutting and the desired finish. The blade’s size, thickness, and diamond grit are also essential factors to consider.

What is the right blade to cut tile?

A diamond saw blade is the right blade to cut tile. The diamond grit and the blade’s thickness will vary based on the type of tile being cut.

What is the best tile blade for tile saw?

The best tile saw blade for cutting tile is one with a high-quality diamond grit and a proper thickness to avoid chipping and breaking.

Which blade is best for cutting vitrified tiles?

A continuous rim diamond blade with a high diamond concentration is the best for cutting vitrified tiles.

How do I choose a saw blade for different materials?

You should choose a saw blade based on the material you are cutting. Different materials require different blade types, sizes, and thicknesses.

Is there a difference in tile saw blades?

Yes, tile saw blades differ in their diamond grit, blade thickness, and size. They are also designed for cutting different types of tile.

How do you cut tile perfectly?

You can cut tile perfectly by marking the tile, making a shallow cut first, and then deepening the cut with slow and steady movements. Ensure that the blade remains cool by using water.

How do you cut tile perfectly straight?

You can cut tile perfectly straight by using a straightedge as a guide, keeping the saw blade steady, and ensuring that the tile remains in place throughout the cut.

What do professional tilers use to cut tiles?

Professional tilers typically use a tile saw with a diamond blade to cut tiles.

What type of diamond blade is best for cutting tile?

A continuous rim diamond blade is the best for cutting tile. The blade’s diamond grit and thickness should be selected based on the type of tile being cut.

See Also:

- Best miter saw blade for fine cuts

- Best miter saw blade

- Best metal cutting circular saw blade

- Best jig saw blade for plywood

- Best dado blade for table saw