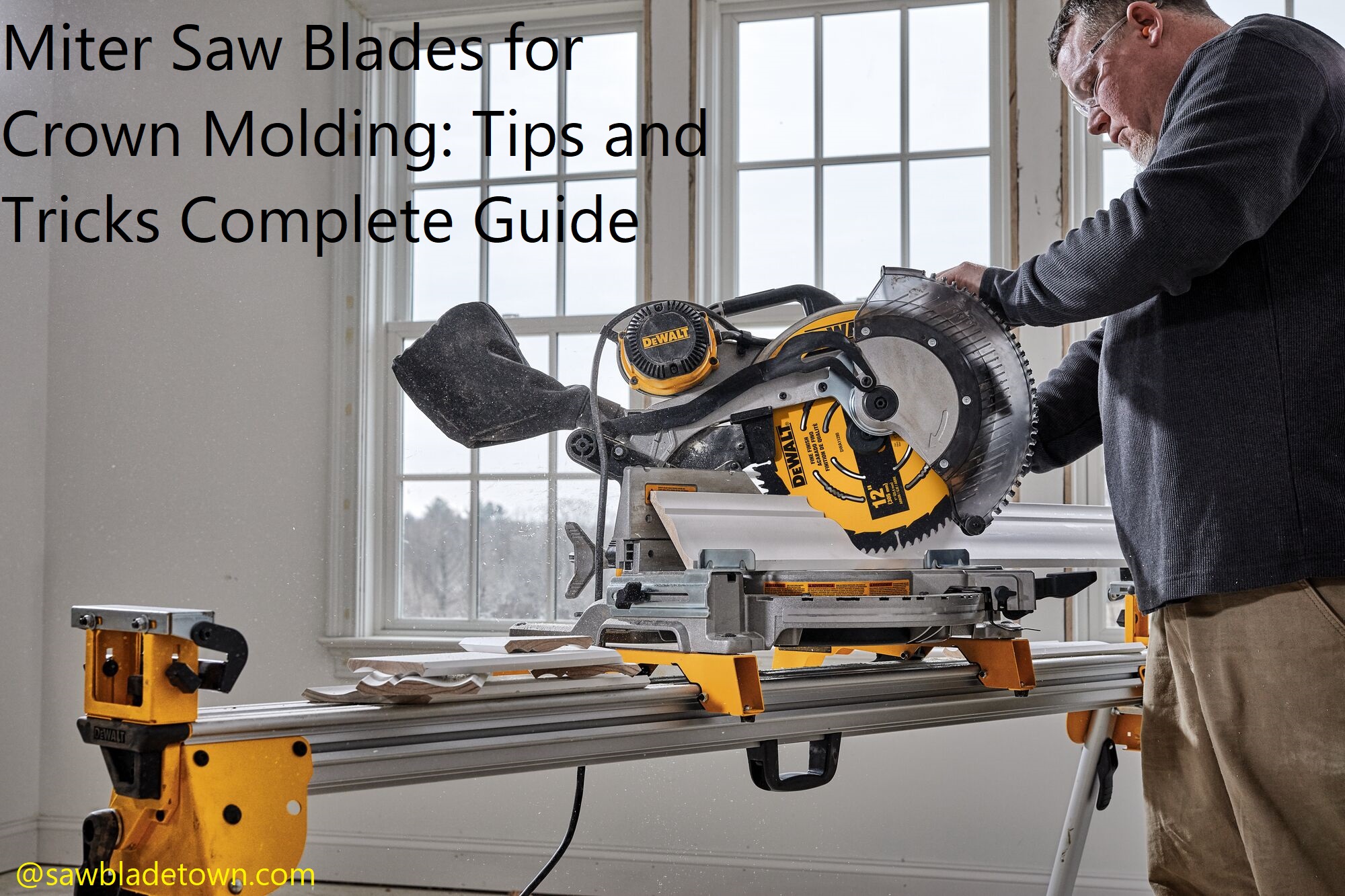

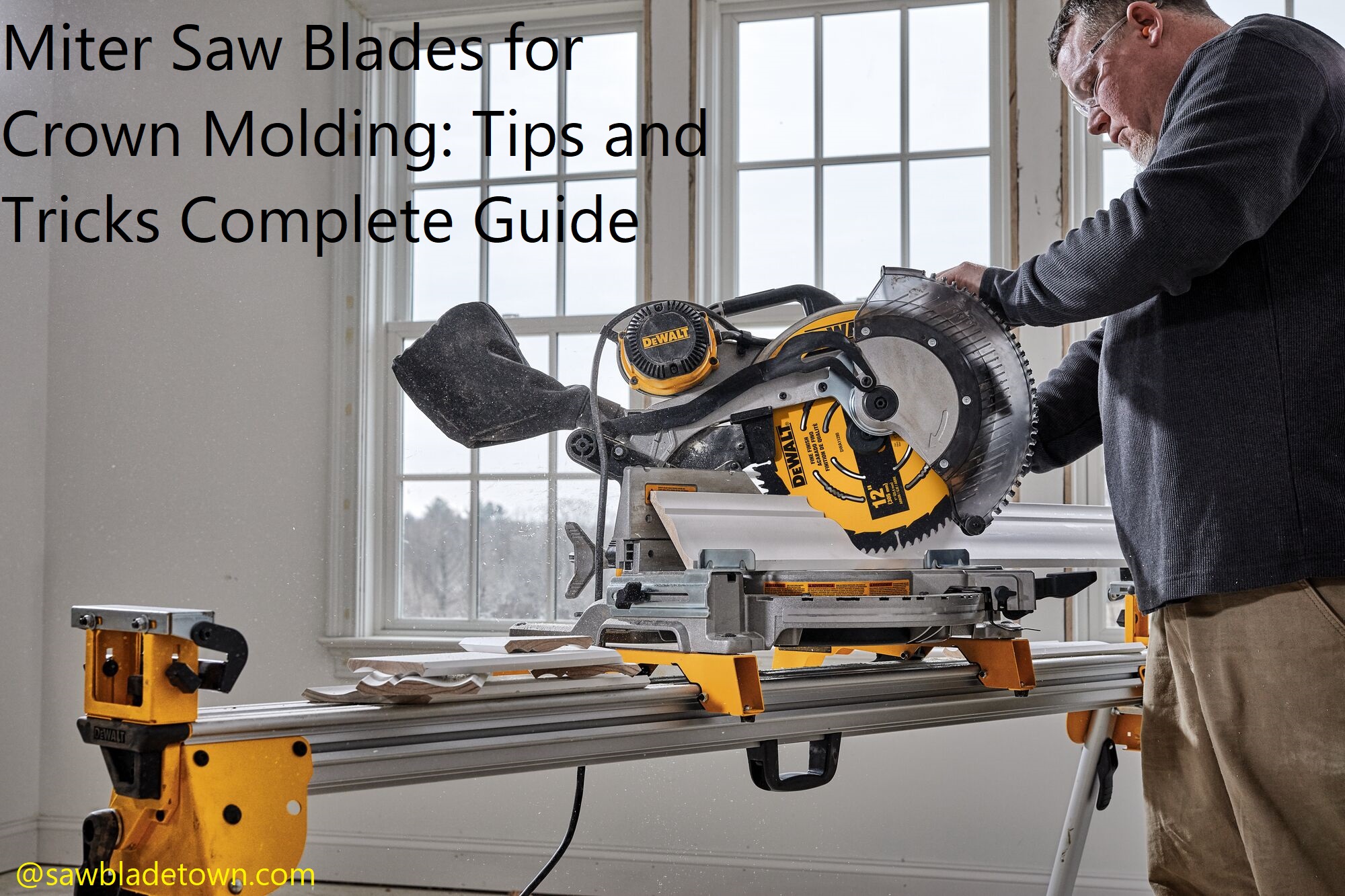

Are you looking to create stunning crown molding but don’t know how to choose the right miter saw blade?

This comprehensive guide provides all the tips and tricks you need to make accurate and precise cuts with ease. Get ready to take your crown molding projects to the next level!

Introduction

The introduction of miter saw blades for crown molding has revolutionized the process of trimming and cutting expensive hardwood materials used in crafting fine furniture and other woodworking projects. Now, with the right tools and safety measures, any homeowner can create perfect miter cuts and add custom touches to projects that require professional-grade results.

In this comprehensive guide, you will find tips, tricks and techniques for using miter saw blades for crown molding to make impeccable crown molding projects. We’ll discuss everything from proper setup, convenient tools and methods to use, as well as strategies for ensuring quality results every time. With a little practice and a dedication to safety precautions, you’ll be able to create stunningly perfect results on your crown moldings with ease.

Definition of miter saw blades

A miter saw blade is a circular saw blade equipped with an angled cutting surface on each side, which allows the user to make precise crosscuts and miter cuts in a variety of materials. Miter saw blades are available in sizes ranging from 6 inches to 14 inches, typically determined by the diameter of the blade. Common materials for miter saw blades include carbon steel, high-speed steel, tungsten carbide, and diamond-tipped blades. Different types of miter saw blades are designed to efficiently cut different types of material from wood to metal. It’s important to properly match a particular type of material with its respective type of blade in order to achieve a quality cut free from tear-outs or chipping.

The angled cutting teeth on miter saw blades determine how smooth or rough the cut will be depending on the contained geometry shape and tip selection (flat top grind FTG). This angle can range between 10 degrees up to 25 degrees which affects both performance and life expectancy when the blade comes into contact with material while cutting. Miter ranges up to 45 degrees are possible using special combinations like taper putty knives or combination blades that offer more angle flexibility than standard models. Furthermore, it’s important to match the correct tooth speed (TSP) rating for specific materials according to recommended Canadian tolerances. The formulation process for each individual material is critical when selecting a grade range typically followed by hardness and toughness testing for best results in extended performance capabilities when cutting difficult materials such as plywood or hardwood joinery applications like log construction projects meant for commercial use.

Importance of using the right blade for crown molding

Using the wrong saw blade for crown molding can produce cuts that are too rough, leading to an unsatisfying finished product. Furthermore, it can cause excessive strain on the saw which could damage or even break your saw and possibly injure you in the process. In order to make smooth, crisp cuts on crown molding, it is important to select a blade that is up to the task. Blades specifically designed for cutting crown molding are available from most major retailers and have certain features that make them ideal for this difficult job.

It is important to keep in mind several features when selecting a saw blade for crown molding: tooth configuration, hook angle, kerf size and plate thickness.

Tooth configuration indicates how aggressively the blades will cut into the material of your choice. Blades designed specifically for crown molding typically have a higher number of teeth per inch (TPI), ranging between 80-100 TPI which helps ensure smoother cuts with less vibration as each tooth makes very small contact with the wood at any given time during use. Hook angle refers to the sharp corner shape of each individual tooth which helps get through corners easily; 56 degree hook angle has been found to work well when cutting through hard woods like Maple or Oak so look for those when selecting blades specifically designed for crown molding. Kerf size refers to how much material is removed by each cut being made by the blade and should be chosen based on what type of material you are cutting; wider blades will hold more material but also more heat build up so they will require more cooling over time if used often while thinner blades cut faster but may vibrate more during use if they become too hot due finally finally plate thickness indicates how thick and durable your selected blade is – thicker plates help eliminate any warping or deformation over time which could lead unprofessional results after repeatedly making many identical cuts through challenging hard woods like maple or oak.

Features to Consider When Choosing a Miter Saw Blade for Crown Molding

With so many miter saw blades for crown molding on the market, it’s important to understand what features to look for when choosing the right blade for your application and project. Here are some important factors to keep in mind when selecting a miter saw blade:

Blade Size – Standard circular saw blades typically range from 6 ¼ inches up to 12 inches in diameter. When cutting crown molding, it’s best to opt for a larger blade which will provide enough power and speed needed to create perfect cuts and avoid any burning of the wood.

Tooth Count – The more teeth a blade has, the cleaner cut you’ll get without burning through the wood. Generally, blades with more teeth will cost more but are an important choice if crisp and clean cuts are desired. For example when cutting cabinet crown molding or other complex profile mouldings an 80 or 90-100 tooth miter saw blade would be an ideal choice.

Blade Material – Most miter saw blades come in either high-speed steel or carbide-tipped versions, with carbide-tipped being the better quality option since it offers increased durability and a longer lasting cutting edge.

Kerf Width – The kerf width is the size of the channel that is cut as a result of passing of a sawblade through material, also known as “blade width.” Larger kerf blades will require more power but offer quicker results while smaller kerfs give you more precise cuts but require use of slower feed rates — so keep this in mind when selecting your blade size.

Blade Diameter

When choosing a blade diameter for cutting crown molding, it’s important to remember that one size does not fit all. The best option depends on the type of material your are using. For example, if you’re cutting soft woods like pine or poplar, then a 7 1/4-inch blade is sufficient. However, if you’re working with harder woods such as oak and walnut, then you need a 10-inch blade that can handle the harder surface.

Other considerations include the type of cut and type of saw. For example, miter saws typically require larger blades than table saws do. Make sure you take into consideration all factors before settling on a blade diameter for your project.

Tooth Count

The type of blade often referred to as a “finish blade” has between 80 and 100 teeth. If the radius of the molding is 1-5/8 inches or less, then a finer, more detailed cut can be achieved using blades with fewer teeth (between 40 and 60).

A blade with more teeth will give you a smoother finish on wider molding because it will have more cutting edges. The ideal tooth count depends on the size of your project — if you’re working with larger crown moldings and/or wider cuts, then go for blades that have between 80 and 100 teeth; if you’re working on more detailed, smaller crown moldings, blades that range from 40-60 teeth should suffice.

For instance, an 80 tooth miter saw blade usually produces detail work much better than a 40 tooth saw.

Tips and Tricks for Using a Miter Saw Blade for Crown Molding

It is important to remember that when cutting crown molding, the flat saw blade works much better than other blades. Choosing the right saw blade can help you achieve the best results with minimal effort. Here are some tips and tricks to keep in mind when using a miter saw blade for crown molding:

-Choose a saw blade that fits the size of your miter saw. It should be big enough to cut large patterns, but small enough to avoid excessive wear on small pieces.

-Angle cuts are very important in crown molding projects so be sure to measure angles accurately and make parallel pieces. If needed, make a template for reference.

-Using accurate settings is paramount for achieving clean edges and sharp corners when cutting crown molding with a miter saw blade.

-When setting up your miter saw, use laser guides or markings on the back fence of your miter saw as indicators for where exactly you should be cutting your pieces for perfect joints every time.

-Be sure to use safety equipment such as goggles and gloves whenever you’re working with power tools such as compound and sliding miter saws so you don’t injure yourself during production work or intricate pattern work.

-It’s also important to apply a lubricant or wax on both sides of your miter blades before any cuts are made in order to reduce friction heat buildup while cutting; this will extend its life as well as give you better results with each cut!

Proper Cutting Technique

If you’re new to using a miter saw for crown molding, it’s important to learn the correct technique for cutting. This will help you get the best results with minimal waste. Here are a few tips to keep in mind:

- Using a clamp, secure the piece of crown molding that is being cut. This helps ensure a clean and accurate cut each time.

- Set your miter saw blade depth to the depth of the crown molding being cut so that it won’t hit the surrounding trim work when making your cuts.

- For each cut, measure twice and cut once; make sure your measurement is exact before proceeding with your cut.

- When actually cutting, hold the miter saw handle firmly as you start and finish each cut–this will ensure stability throughout the entire process and prevent kickback or other problems while cutting.

- Turn off your miter saw blade after completing each cut; this will help extend its life span by ensuring that there is no excess friction on it until it is needed again.

- Keep an eye on debris while using your miter saw; wear safety lenses or goggles to protect yourself from any flying objects that can potentially be released while cutting.

Blade Maintenance

In addition to selecting the correct saw blade for your project, it is essential to perform regular maintenance to keep your miter saw blades in good working condition. Regular maintenance will extend the life of your blades, maximise their cutting performance and minimise the risk of permanent damage.

Proper cleaning is essential when you maintain a miter saw blade for crown molding. Before cleaning, ensure that the blade has cooled down and all dust and debris has been removed from its surface using a vacuum or brush. To remove resin build-up, which may have accumulated on the blade over time, use a specialised blade cleaner – either an aerosol lubricant or a citrus-based cleaning solvent – and follow all manufacturer’s instructions carefully. Buff away any surface corrosion with steel wool while the cleaner is still present on the blade. When finished with this task, wipe down your miter saw blade with an anti-static cloth and apply a light coat of lubricant to prevent future rusting. Finally, check for any nicks or dings in the teeth of your miter saw that can be sharpened with a file before reattaching it to your machine’s arbor bolt and reassembling it into its housing frame securely.

Safety Precautions

Before setting up and operating your miter saw for cutting crown molding, make sure you are taking the appropriate safety precautions.

Make sure all guards are in place, and wear safety goggles to protect your eyes from sawdust or other flying debris. Be sure to secure your workpiece with clamps or a vice grip so that it does not move during cutting.

Plan ahead — never push material too far into a saw blade; this can damage the blade and lead to kickback. Secure yourself in place while using the saw; always keep a clear line of sight of the blade and do not allow any loose clothing near the moving parts.

When you are finished with the cut, be sure to disconnect power to the motor before cleaning up debris or making adjustments.

Step-by-Step Guide on Cutting Crown Molding with a Miter Saw Blade

A miter saw blade is a power tool designed to make precise cuts in crown molding. As its name implies, the blade is slanted at two angles (miter cut) with the teeth pointing up at a 45-degree angle. To be effective and accurate, there are several steps required for successfully cutting crown molding using a miter saw blade.

Step 1: Pour the Crown MoldingInto the Saw Pour in the crown molding carefully with one hand while holding it firmly against the back of the saw with your other hand to prevent slipping or buckling of the material as it goes through.

Step 2: Select and Lock In an Angle Use the laser guide to determine the exact angle you’d like to cut at. Turn on your saw and line up your material with this angle, keeping your hands away from any moving parts. Once you’re ready to make a cut, use your thumb or finger to lock in this angle by pushing down on locking mechanism on top of your saw blade handle.

Step 3: Guide The Blade Through The Molding With Light Pressure Start out gently as you move forward along material with light but steady pressure until complete desired cuts are made all across pieces of wood used in crown molding project. Be sure not to overexert and force excess pressure onto material as this can damage both miter saw and piece being cut.

Step 4: Unlock & Reset Saw Blades Angle As Needed Orientation can’t always be determined without first unlocking angle which requires disengaging locked button back into home position before rotating angled shaft around so that new settings match those desired settings already established within laser guides original reading once more adjustments have been made accordingly once again according locks dial has been pulled down properly so that cutting rotation carries forth evenly across remaining surface area left within multiple layered design structure making it easier create seamless appearance ultimately bringing ultimate vision life which was initially started during plan’s development cycle from initial conception until final deployment takes place effectively giving property new found visual injection potential buyers will surely appreciate now that every step taken along journey has been set into motion allowing such luxurious details reflect upon surfaces without fail leaving impeccable word class quality behind each time finished.

Measuring and Marking

It’s time to get started! Before you reach for the saw and start cutting, measuring and marking is key in a successful crown molding installation. Whether you use traditional methods of transferring measurements or speedy electronic gadgets, you need to ensure that your markings are precise. Here are some tips to ensure accuracy in your crown molding project:

-Measure all pieces twice before making any cuts and measure entire walls if possible. This will prevent mismeasurement which could have costly results.

-Mark all walls and the back of the molding with pencil markings where each cut, miter, and coping will be made. Use a framing square or a speed mark tool to make accurate lines for cuts, miters, copes, etc.

-Mark for miter or cope cuts by using two straight edges to establish the angle between two moldings as well setting exact degrees from 0° up to 45° on outside corners and from 0° up to 90° on inside corners.

-On inside corners, mark a line from each wall intersection onto both ends of the molding at 45° angles away from the corner. On outside corners, mark a line onto the end of the left side piece at 45° angle when facing towards it and down into wall intersection point on right side piece – this is a very important line that must be precisely marked as it is used both for cutting of miter as well against table saw blade when making copes.

Cutting the Crown Molding

Once you have chosen the right blade for your miter saw, the next step is to actually cut the crown molding. The secret to achieving a successful cut is in the technique. Here’s how to get it right:

1.Measure twice, cut once. This rule applies to all types of cutting, but is especially important for crown molding – it’s better to take your time and ensure a perfect fit than to rush and end up with incorrect measurements.

2.Attach a blade guard. Using a blade guard helps ensure safety as well as accuracy, so be sure to attach one before every use.

3.Set the material at an angle (~45°), and make sure it sits flat on both sides of the saw-base before cutting it carefully along the marked path with easy strokes of the saw handle

4.Support the length of crown on both sides while cutting; this will reduce vibration and yield a cleaner cut line

5.Somemiter saws come with a clamps that can hold dowels when cutting wide pieces; these are great if you own one!

Conclusion

In conclusion, choosing the right saw blade is an important step for successful crown molding installation. The number of teeth needed can vary depending on the size and complexity of your project. One of the most important factors for ensuring a quality cut is using a saw blade specifically designed for crown molding.

Using the wrong saw blade when cutting uneven shaped moldings can lead to inefficient cutting, damage to your materials, and inaccurate results. Finally, make sure your blade is fitted properly with a sharpened tooth profile made from high-quality steel to ensure long-lasting performance.

With these tips in mind, you can be sure that you’re able to get the best results from your miter saw when you begin cutting crown moldings.

FAQ’s

What is the trick to cutting crown molding?

The trick to cutting crown molding is to cut it upside down and backward using the appropriate miter and bevel settings.

How do you adjust a miter saw for crown molding?

To adjust a miter saw for crown molding, you need to set the miter angle and bevel angle according to the manufacturer’s instructions and the crown molding’s spring angle.

What is the best saw blade to cut crown molding?

A fine-toothed, carbide-tipped saw blade with at least 80 teeth is the best saw blade to cut crown molding.

Why is 31.6 on a miter saw?

31.6 degrees is the angle between the table and the blade on a miter saw, which is the most commonly used angle for cutting crown molding.

What angle is crown molding cut at?

Crown molding is typically cut at a 45-degree angle, but the angle may vary depending on the spring angle of the molding and the corner angle.

How do you align a miter slot blade?

To align a miter slot blade, you need to adjust the fence, blade, and miter gauge according to the manufacturer’s instructions.

How do you align a miter saw blade?

To align a miter saw blade, you need to adjust the bevel and miter settings, blade depth, and fence according to the manufacturer’s instructions.

What is the compound angle for crown molding?

The compound angle for crown molding is the combination of the miter angle and the bevel angle, which can vary depending on the molding’s spring angle and the corner angle.

Which saw blade makes the smoothest cut?

A blade with a high tooth count and a fine tooth pitch makes the smoothest cut, but the blade type also depends on the material being cut.

What is a 40 tooth saw blade used for?

A 40 tooth saw blade is used for making general-purpose cuts in wood, metal, and other materials, but it may not provide the smoothest cut.

See Also:

- Best circular saw blade

- Best chop saw blade for metal

- Best chain saw blade

- Best blade for radial arm saw

- Best band saw blade for stainless steel tubing