No woodworker wants to sacrifice accuracy for convenience, yet that’s often the trade-off when trying to decide which saw blade to use. You’re in luck; this article will provide you with a comprehensive guide on when and how to use a 12 inch miter saw blade.

Ensure your projects come together perfectly with the right saw blade!

Introduction

The 12 inch miter saw blade is an essential tool for many projects. It is a powerful, cutting tool designed to make precise cuts in various materials such aswood, metal, composites and plastic. While the blade can be used to cut straight lines, it is also ideal for making angle cuts at different degrees of accuracy. This versatile tool can be used in a variety of applications ranging from cutting decorative trim pieces to constructing furniture frames.

In this guide, you’ll learn the basics of how to choose and use a 12 inch miter saw blade for your projects. We’ll discuss the differences between types of blades and when each type is best used as well as tips on purchasing blades and properly maintaining them to get the best performance out of your saw. By the end of this guide you should have a better understanding of which type of blade will suit your project needs and how to use it properly for maximum precision and performance.

Understanding Miter Saw Blades

A miter saw blade is an essential component of any miter saw. It is installed in the miter saw and it is responsible for making precise cuts in different types of materials. Miter saw blades come in a variety of sizes and materials, each designed for a specific purpose. The 12-inch miter saw blade is one of the most popular choices because it can make very accurate cuts at greater depths than other blades. This size is perfect for cutting deeper into hardwoods, sheetrock, and laminate flooring.

In this article, we will discuss when to use a 12 inch miter saw blade to get the best results from your cut.

Types of Miter Saw Blades

No two miter saw blades are ever the same, as there are a variety of options available based on the job you’re attempting to complete. 12 inch miter saw blades are an excellent choice for a variety of projects, and these blades have several features that set them apart from other types of saw blades. Before deciding if a 12 inch miter saw blade is right for your job, it is important to understand what makes them unique and in what situations they should be used.

Most miter saws can accommodate a variety of blade sizes and types, but the most common sizes are 8 inch, 10 inch and 12 inch blades. Each size has its own advantages and disadvantages when it comes to cutting materials. In general, larger blades provide more power and stability when cutting thicker pieces or materials that require precision cuts. A 12 inch miter saw blade is the largest size available and provides users with increased cutting power along with improved visibility while on the job site. These large-diameter blades also offer greater accuracy when it comes to making precision cuts in challenging materials like steel or hardwood.

When choosing between different types of miter saw blades, there are several factors that need to be taken into consideration such as size, material type, tooth count teeth/inch (TPI), kerf width and hook angle. Generally speaking, lower TPI results in faster cuts but rougher edges while higher TPI result in slower cuts but smoother edges due to the extra teeth per blade configuration. In terms of hook angle this will affect how aggressively the blade digs into the material being cut so choosing the right hook angle for your project can be critical depending if you are working with softer woods or tougher metals. Lastly, while making your selection consider kerf width, which effects how much material is removed per cut. A wider kerf width will reduce total cutting time but also may produce unwanted tear out on surfaces or reduce accuracy in finer detailed cuts.

Miter Saw Blade Sizes

The size of a miter saw blade is measured by its diameter, ranging from six to fifteen inches. In most cases, the larger the saw blade diameter is, the harder and faster it can cut through wood. The size of the miter saw blade that one should use depends on several factors including the desired cutting shape, speed of cutting, cost, available power supply and materials to be cut.

Six-inch blades are typically used for light-duty cutting in soft woods and plywood where accuracy is not too important. They are also popular for craftsmen who use them for trimming edges or small radius curves in moldings.

Eight-inch blades can give more accurate cuts in lighter materials than smaller blades however they tend to be slower at cutting than larger diameter blades due to their reduced thickness which can lead to chattering when used on hardwoods.

Ten-inch blades provide an excellent balance between speed and accuracy with most users able to get an acceptable job quality out of them when used correctly with correct setting; they are commonly used by both professional tradesmen and home enthusiasts alike.

Twelve inch blades usually vary in tooth count depending on whether they are classified as general purpose or dedicated blades; they tend to provide good performance levels when used with moderate feed rates while still being able to handle harder woods with ease.

Generally considered large-diameter miter saws, fourteen-inch models provide a great level of stability as well as enabling faster feed rates for high production work environments, such as carpentry shops or demolition companies. Fifteen-inch blades are generally reserved for high production applications due employees operating these machines needing significant strength due their great weight and massive amounts of torque created during operation.

Miter Saw Blade Teeth

The number of teeth determines the type of miter saw blade used. To complicate matters, miter saw blades come in a variety of tooth configurations to accommodate various materials being cut. The most common tooth configuration is the alternate top bevel (ATB). The ATB grind has alternating teeth with a left-offset angle and a shorter face above it. This combination produces clean cuts at both top and bottom surfaces.

A triple-chip grind (TCG) blade has three sections or edges on each individual tooth for additional cutting power that produces cleaner cuts on hard or abrasive materials like melamine and plywood edges, countertops and laminate flooring.

What is a 12-inch Miter Saw Blade?

A 12-inch miter saw blade is the largest size of blades available for miter saws and is typically used for larger projects such as cutting large molding or baseboard.

The size of the blade directly correlates to the size of projects that it is able to cut since a larger blade will enable cuts with a greater depth. This can make larger projects easier due to the lack of multiple passes are needed in order to cut through with precision, however, when not properly used, it can be dangerous and require more power from the machine.

Understanding the blade size

The size of a miter saw blade is measured by the diameter from one tip to another. A 12-inch blade, for example, has an overall diameter of 12 inches. Of course, some blades are also designated in millimeters; for instance, a 12 inch blade might have a designation of 305mm.

When it comes to miter saw blades, size is not the only factor to consider. You’ll also need to think about the number of teeth on the blade and their pattern arrangement. More teeth will typically result in better accuracy or smoother cuts, but it might also mean longer cut times or reduced capacity when cutting through larger materials such as plywood or composite decking. It’s important to understand that there’s a tradeoff between speed and precision when it comes to miter saw blades, so be sure to evaluate your needs carefully before making a purchase.

Once you have chosen your ideal blade size and tooth count combination, you can then consider other features such as whether it should have an anti-vibration mechanism or degree markings on its base plate. Knowing what features are important can help you find the most suitable 12 inch miter saw blade for your needs.

Advantages and disadvantages of a 12-inch Miter Saw Blade

The 12-inch miter saw blade is one of the most popular blades for all types of woodworking and carpentry tasks. Using this blade can provide many distinct advantages, but it also has certain downsides that must be taken into account before making a purchase. With this guide, we’ll explore both of these factors to help you make an informed decision about whether a 12-inch Miter Saw Blade is right for you.

Advantages: Using a 12-inch miter saw blade allows you to work with bigger pieces of wood than you would otherwise be able to with a smaller blade. The longer teeth on the 12-inch blade mean that it can cut deeper into materials and offer better results when making longer cuts. The increased size also gives added stability while cutting, which makes the task simpler and produces more accurate results.

Disadvantages: Though advantageous, there are some downsides to using a 12-inch miter saw blade as well. The larger size may make narrow cuts and intricate projects difficult or impossible to complete with this type of blade due to its thickness and length. Additionally, even though it is capable of making bigger cuts than smaller blades, it cannot reach quite as deep as a 10 or 8 inch model can due to its size restrictions.

When to Use a 12-inch Miter Saw Blade?

When deciding when to use a 12-inch miter saw blade, the main considerations are the type of material you are cutting and the desired finish. The larger diameter blades can create smoother cuts in thicker material like wood, plastic and metal. For more delicate materials, smaller blades tend to produce better results.

Essentially for any regular miter cut, 12 inch blades should be your go-to choice. This is especially true when creating perfect angular cuts on intricate or detailed wooden pieces or furniture and décor projects. The larger blades also provide excellent cuts for crown moulding work where accuracy is essential.

For any long pieces of lumber that need straightening and cutting, it’s best to opt for a 12-inch miter saw blade as they will be powerful enough to cut cleanly though such thick materials and in one pass producing an elegant finish with minimal effort required on your part.

If you want a deeper or narrower cut in metals like aluminum alloys, copper or brass then smaller 9 or 10 inch miter saw blades may be more suitable for achieving those desired intents due to their greater accuracy than 12 inchers at those thinner depths of materials. That said remember that this only applies if precision precision is required above all else; if an effective job needs doing quickly then twelve inches is still the way to go!

Understanding the cutting requirements

To determine the type of blade you need for your miter saw, it is important to understand the cutting requirements. Different blades excel in different types of jobs, so it is essential to select the correct one for your project.

For instance, a 10-inch blade designed for crosscutting isn’t your best choice for cutting thick lumber due to its lack of depth. It can also make a difference if you’re dealing with hard or soft wood — some blades will provide better cutting performance on one material over another. Here are some general tips when selecting a miter saw blade:

- For ripping thick material (hard or soft woods), choose an appropriate 12 inch saw blade with 60 teeth (or more).

- For cutting laminate countertops and trim, choose a dedicated laminate blade like the Forrest SM12800300 circular saw blade which has 100 teeth and boasts anti-vibration technology.

- If you want a bit more control with delicate crosscutting tasks, consider a 12 inch combo saw blade with alternating tooth direction — this will help minimize chip out on fine woodworking projects including boxes and furniture.

- If you plan on dadoing frequently or need extra depth capacity, look for a high ATB angle 12 inch saw blade; these have up to 90 degree angle indicating more aggressive bevel angles which allow them to handle deeper cuts while providing super smooth finishes.

Understanding the Material type

Knowing the type of material you will be cutting is key when determining ton which blade you should use. Whether it is wood, plastic, metal, or some other material all have significantly different characteristics that require the need to use different blades. The most common types of material and the suitable saw blades are as follows:

Wood: A general purpose, standard 24 teeth per inch (TPI) blade is good for cutting softwoods, hardwoods, and plywood. A more coarse/aggressive blade such as 12 TPI will cut more quickly but may leave a rougher finish than a blade with finer teeth.

Plastic: Generally a fine-toothed (80 to100 TPI), similar to a “triple-chip” design work best when cutting plastics like PVC and polycarbonate sheeting.

Metal: Since metals are harder than wood or plastics they require a higher tooth count for a smooth finish — 80 to 120+ TPI depending on what type of metal you are cutting. Generally speaking cold rolled steel and aluminum both can be successfully cut with an 80-96 TPI sawblade.

How to Use a 12-inch Miter Saw Blade?

Using a 12-inch miter saw blade can provide a thorough and precise cut. For making crosscuts, especially in long pieces of wood, a 12-inch saw blade cuts faster, more accurate and deeper than smaller blades. Depending on the type of material you are cutting, there are different performance characteristics that you should be aware of before using your 12-inch miter saw blade.

Before beginning to cut any material with a 12-inch miter saw blade, make sure that the blade is secure in the saw. Be sure to refer to your owners manual for instructions on proper installation. To ensure its stability and prevent wobbling when you begin cutting, hold the wood firmly down against the table. This will keep your hand away from the rotation of the sawblade and reduce vibrations throughout the cutting process.

Cutting laminates such as plywood or particle board require slower speeds and feed with more downward pressure from the operator than when cutting solid wood materials like oak or pine. This will result in cleaner edges while minimizing chipping around your workpiece. Without ample speed and pressure during this type of cut, large chipping or fragmentation can occur due to tear out or demolition caused by stress occur under high velocity conditions on thin structures like laminates.

When cutting softer materials like aluminum or plastic be mindful not to push too hard onto your work piece; otherwise it may result in binding or kickback due to uneven tension within the blade itself because they tend to melt fairly easily while being cut under high rotational speeds at small diameters like twelve inches. To prevent melting as well as incrementally reducing friction heat build up try increasing your overall speed by one hundred percent (100%) varying from tooth area which is at maximum four hundred rpm’s (400 RPM’s) for aluminum then dropping it back down when reaching an acceptable level at five hundredth percentage (50%0) for plastic. The slower speed aids in keeping heat under control with controllable feed methods being used technique now called “Scraping” having amazing results for all soft materials, generating cleaner edges all whilst having little effecting fretting out force generated from friction posing no threat danger wise.

Setting up the Miter Saw

Setting up your miter saw for the 12 inch blade is critical for the best results when performing even the most basic of cuts. Here are a few important steps to follow when setting up your miter saw:

- Before you begin, ensure that your saw is unplugged.

- Use a hex key or use whichever type of wrench fits with your saw to loosen and remove the throat plate from under the blade itself.

- Place and secure your new blade on the arbor’s threads or assembly arm in accordance with your miter saw’s instructions manual and tighten it firmly to keep it in place but not over-tightened which could be cause for future problems instead of future solutions; be sure to wear soft gloves whenever you perform this process as sharp blade edges can cause potential injuries if handled improperly

4.Place back the throat plate into its original position beneath the blade and tighten it securely into place

- Make sure all clamps, handles, or other mechanisms are securely tightened and out of harm’s way before moving on to your next stage

6.With everything in position, plug in your miter saw before continuing on with making any further cuts

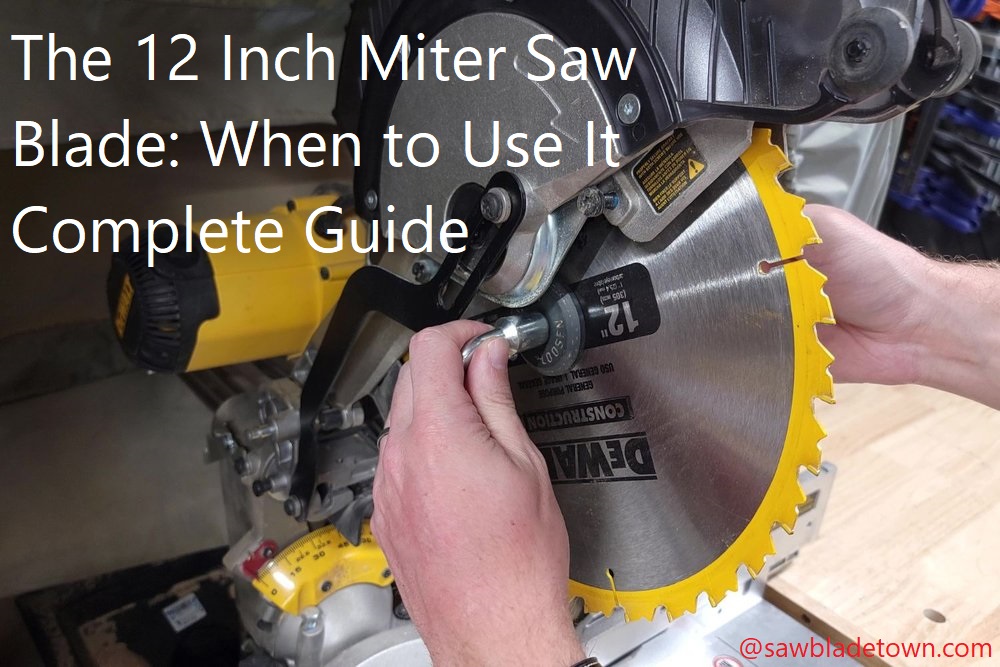

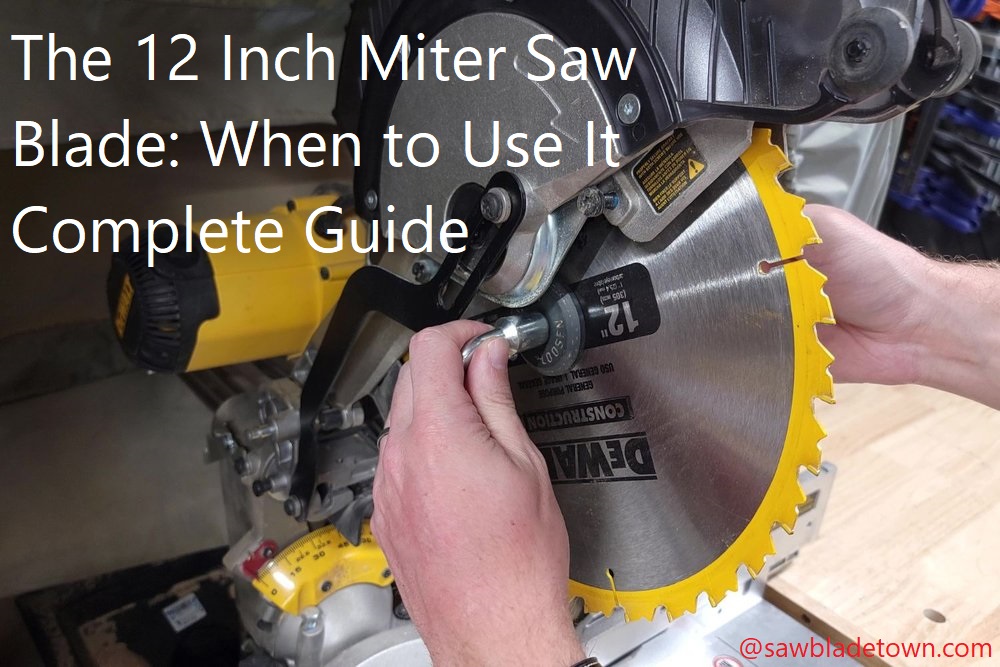

Mounting the 12-inch Miter Saw Blade

Once you have chosen the right miter saw blade that fits your needs and is compatible with your saw, the next step is to mount it on the saw. Be sure to refer to your owner’s manual when mounting a new saw blade on your miter saw. Generally speaking, mounting the 12-inch miter saw blade involves taking away or adding a few of the necessary pieces from the arbor assembly of the miter saw.

Firstly, loosen the arbor nut with an adjustable wrench in order for it to be removed if it is unable to be removed by hand. Hold down the shaft or spindle of the miter saw using a spin handle or using a second adjustable wrench in order for any components of the arbor assembly such as a washer or bearing plate not to rotate during this process. To mount and secure the blade onto its arbor, begin by sliding either side of its inner hub through alternating slots on both sides of your miter saw’s arbor assembly. Return all other pieces of an existing arbor assembly that have been taken off back in their position before tightening them along with an existing flat washer and an integrated star this back onto its original position in order for every component inside its assembly cabinet including a pulley retaining clip to stay securely intact.

Once you have reassembled all parts into their original positions, use one adjustable wrench on one side while holding down an opposing end with another adjustable wrench near its exterior edge before finally securing things up tight with it’s provided locking screws. Finally, slide it onto its accompanying spindle before tightening up everything one last time!

Conclusion

Choosing the right blade for your miter saw helps ensure that your project is completed safely and efficiently.

In conclusion, the 12” miter saw blade is ideal for larger projects as it will allow you to make deeper cuts quickly and decisively. It can also be used on smaller projects, but depending on the size of the workpiece being cut, a 10” or 8” blade may be better suited for accuracy.

In order to select the appropriate type of blade, you need to consider what material you are cutting, the size of your workpiece and how much detail you want in your finished product. When in doubt about which type of blade is best suited for any particular project, consult an experienced home improvement professional.

FAQ’s

What is a 12 miter saw used for?

A 12 miter saw is a power tool used for making angled cuts on wood, metal or other materials.

When would you use a miter saw?

A miter saw is used for making precise crosscuts, miters, and bevels on materials like wood, metal or plastic.

How do you use a miter saw blade?

To use a miter saw blade, install it onto the saw, align the material to be cut, adjust the angle and depth settings, hold the material securely, and then activate the saw blade.

What is the most common reason to use a miter saw?

The most common reason to use a miter saw is for cutting precise angles on material, such as for making frames or molding.

What is the most common use of a miter saw?

The most common use of a miter saw is for making crosscuts and angled cuts on materials like wood.

Why use a miter saw vs circular saw?

A miter saw is typically used for making precise angled cuts, while a circular saw is better for making straight cuts or long rip cuts.

Do I need a 12 miter saw?

The size of miter saw you need depends on the type and size of the material you plan to cut. A 12-inch miter saw is ideal for cutting larger material.

How do you use a miter saw for beginners?

For beginners, it’s important to read the manual, wear protective gear, secure the material being cut, and start with simple cuts at low speeds until you get comfortable with the tool.

What are 3 functions of the miter saw?

The 3 functions of a miter saw are to make crosscuts, miter cuts, and bevel cuts.

How do you cut perfectly with a miter saw?

To cut perfectly with a miter saw, use a sharp blade, properly align and clamp the material, set the appropriate angle and depth, and take your time making the cut.

See Also:

- Best circular saw blade

- Best chop saw blade for metal

- Best chain saw blade

- Best blade for radial arm saw

- Best band saw blade for stainless steel tubing